Method for remanufacturing positive electrode material from waste lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in the fields of remanufacturing positive electrode materials from waste lithium ion batteries and recycling waste lithium ion batteries, can solve problems such as recycling and remanufacturing of lithium ion batteries that have not yet been discovered, and achieves improved electrochemical performance, Effective enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

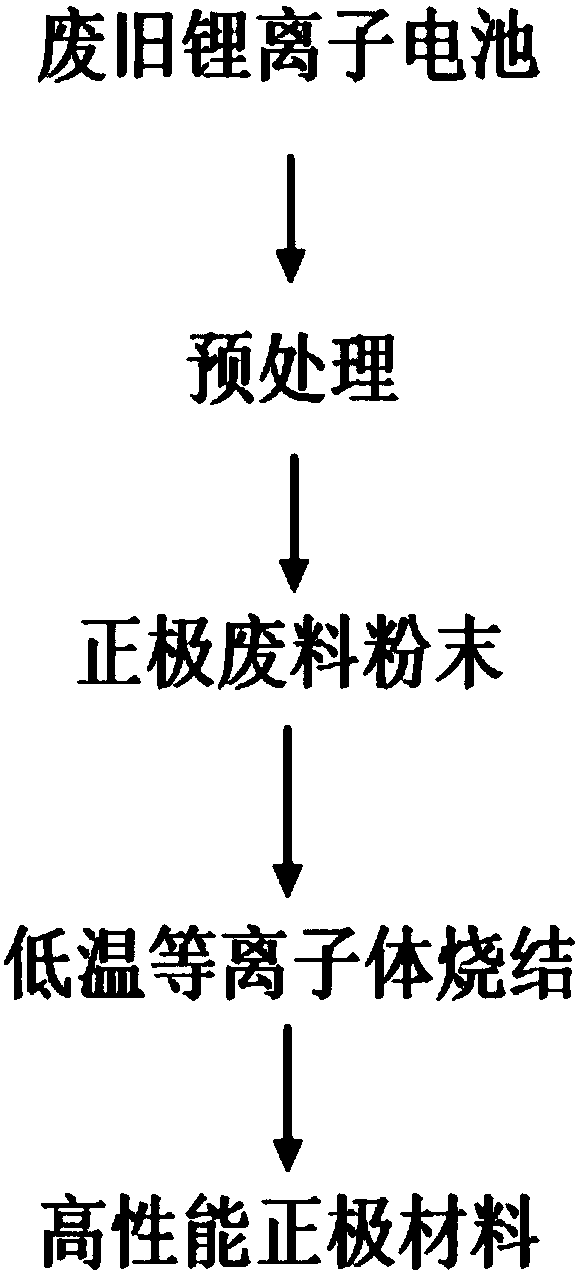

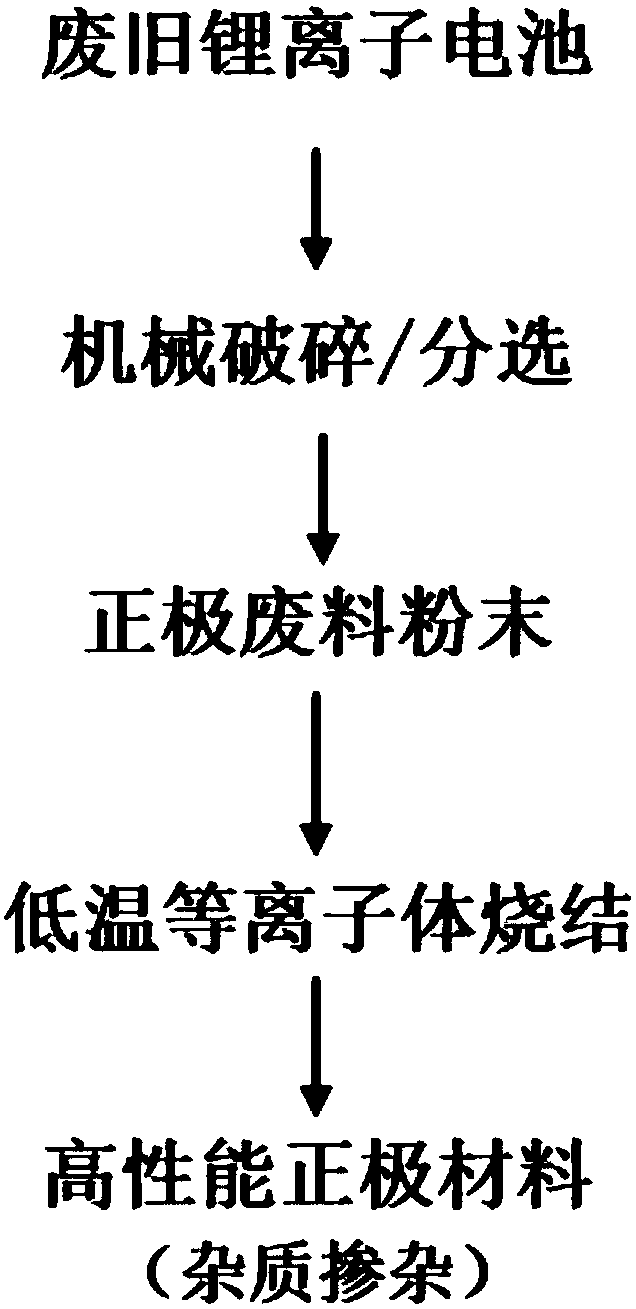

[0074] like figure 2 As shown, a method for remanufacturing a positive electrode material from a waste lithium ion battery includes the following steps:

[0075] (1) Mechanically crush a positive electrode waste or waste lithium-ion battery, and remove the outer shell of the lithium battery through multi-stage crushing, so that the plastic and iron filings are separated from the electrode active material under the action of gravity or magnetism, so as to realize the enrichment of the electrode material. Collected and sorted to obtain positive electrode waste powder.

[0076] (2) Control the composition of the obtained cathode waste powder, set the frequency of the plasma transmitter to 30MHz, the power to be 500W, select DC glow discharge, and then sinter in a low-temperature plasma of 600°C for 240min, and obtain the repairing improvement. High-performance cathode material after characterization.

[0077] (3) Take 5 g of the high-performance positive electrode material pre...

Embodiment 2

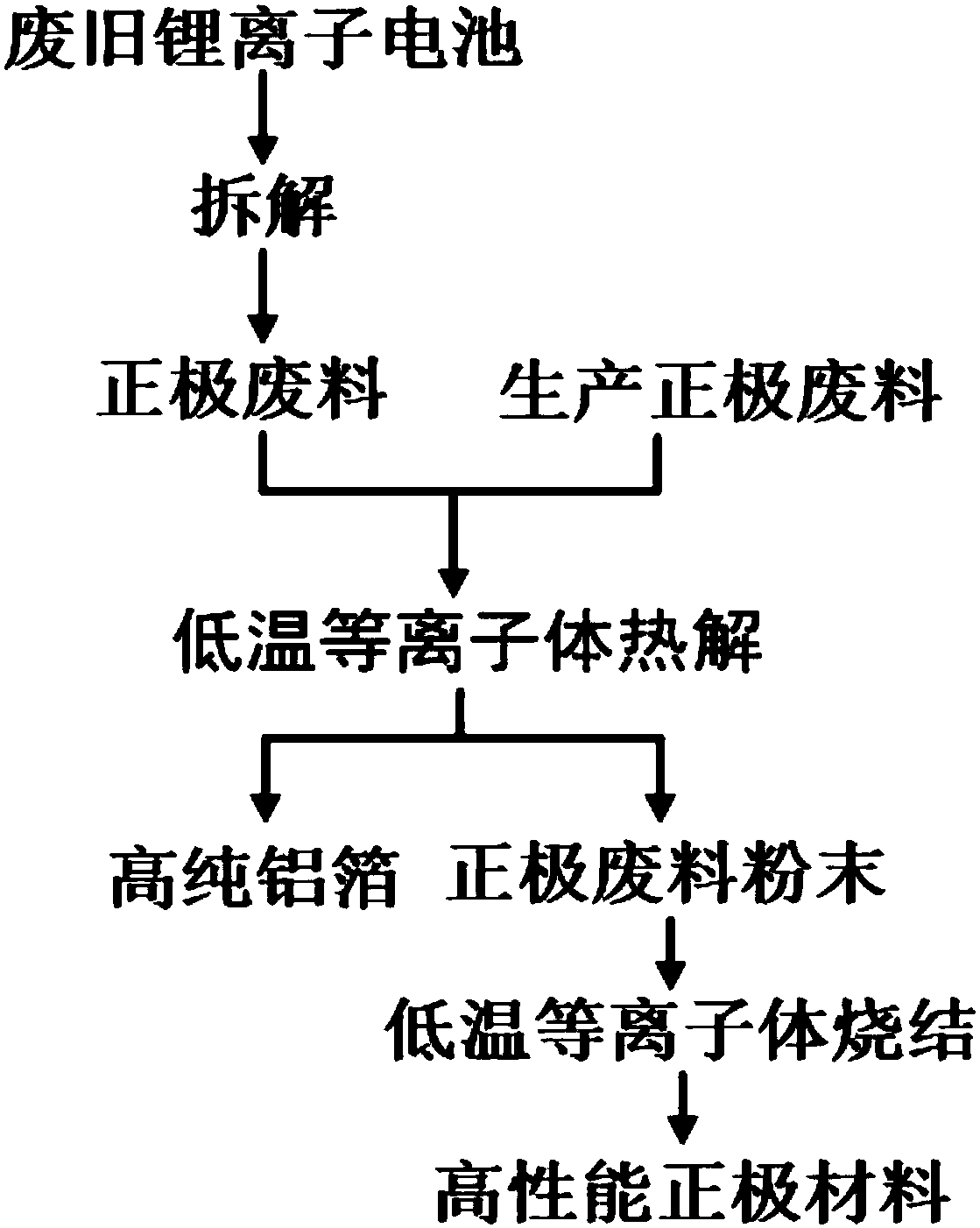

[0079] A method for remanufacturing a positive electrode material by using a waste lithium ion battery, comprising the following steps:

[0080] (1) The waste lithium-ion battery is directly disassembled to obtain a positive electrode waste with aluminum foil. The frequency of the plasma transmitter is set to 30MHz, the power is 500W, the dielectric barrier discharge is selected, and the obtained positive electrode waste is strengthened under a low temperature plasma of 500 ℃ for 240min, the binder is decomposed, and the high-purity aluminum foil is separated, and the positive electrode is obtained at the same time. Scrap powder (may contain acetylene black etc.).

[0081] (2) Control the composition of the obtained cathode waste powder, set the frequency of the plasma transmitter to 25MHz, the power to be 400W, select the dielectric barrier discharge, and then sinter in a low-temperature plasma of 500℃ for 150min to obtain the repair modification. high-performance cathode ma...

Embodiment 3

[0084] A method for remanufacturing a positive electrode material by using a waste lithium ion battery, comprising the following steps:

[0085] (1) Directly collect the discarded positive electrode containing aluminum foil current collector to obtain a positive electrode waste with aluminum foil. The frequency of the plasma transmitter is set to 25MHz, the power is 400W, the high-frequency induction glow discharge is selected, and the obtained cathode waste is strengthened under the low temperature plasma of 400℃ for 150min, and the binder is decomposed, thereby separating the high-purity aluminum foil. At the same time, positive electrode waste powder is obtained.

[0086] (2) Control the composition of the obtained cathode waste powder, set the frequency of the plasma transmitter to 20MHz and the power to 350W, select high-frequency induction glow discharge, and then sinter in a low-temperature plasma of 400°C for 100min to obtain Repair the modified high-performance catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com