A kind of antitumor pharmaceutical composition and its preparation method and application

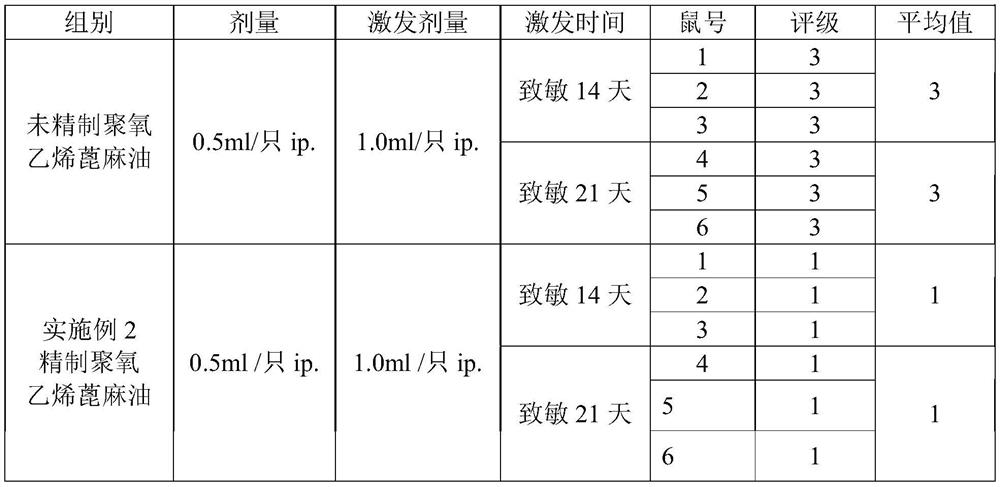

A composition and anti-tumor technology, applied in the field of anti-tumor drugs, can solve problems such as difficult to effectively control adverse reactions of products, high safety risks of clinical medication, and poor drug compliance of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

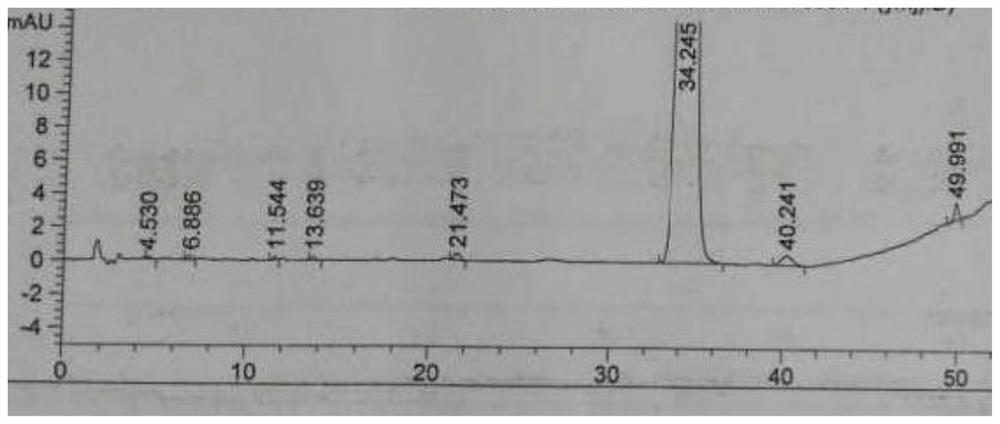

[0046] Embodiment 1 polyoxyethylene castor oil refining method

[0047] Take 1 part by weight of polyoxyethylene castor oil and add 1.4 parts by weight of acetonitrile to dissolve it, add 1.4 parts by weight of cyclohexane to extract, stir at 150r / min for 15min, put it in a water bath at 30°C, and let it stand for stratification to obtain the acetonitrile solution of the lower layer; Acetonitrile solution, adding 1.4 parts by weight of cyclohexane for extraction, stirring at 150r / min for 15min, standing in a water bath at 60°C for stratification, and obtaining the lower layer of acetonitrile solution; repeating the extraction with cyclohexane for 4 times, and the final acetonitrile extract in In a water bath at 40°C, acetonitrile was removed by rotary evaporation to obtain refined polyoxyethylene castor oil.

Embodiment 2

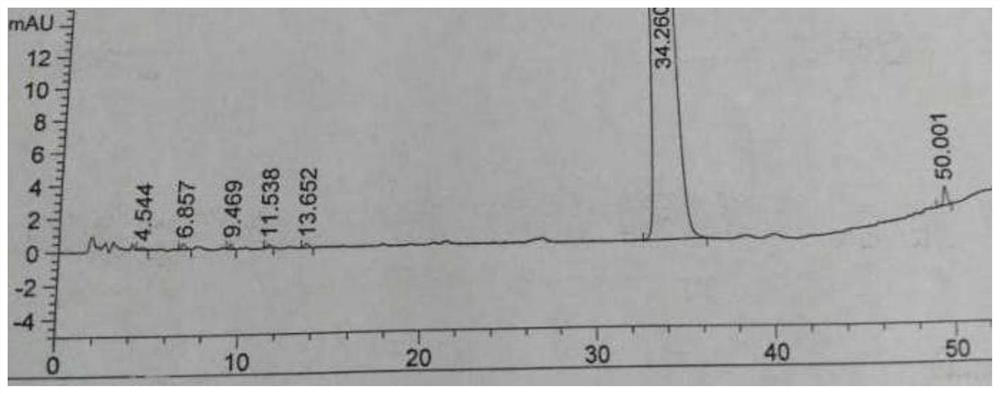

[0048] Embodiment 2 polyoxyethylene castor oil refining method

[0049] Take 1 part by weight of polyoxyethylene castor oil and add 1.6 parts by weight of acetonitrile to dissolve it, add 1.6 parts by weight of cyclohexane to extract, stir at 150r / min for 15min, put it in a water bath at 55°C, and let it stand for stratification to obtain the acetonitrile solution of the lower layer; Acetonitrile solution, adding 1.6 parts by weight of cyclohexane for extraction, stirring at 150r / min for 15min, standing in a water bath at 55°C for stratification to obtain the lower layer of acetonitrile solution; repeated extraction with cyclohexane for 3 times, and the final acetonitrile extract in In a water bath at 55°C, remove acetonitrile by rotary evaporation to obtain refined polyoxyethylene castor oil.

Embodiment 3

[0050] Embodiment 3 polyoxyethylene castor oil refining method

[0051] Take 1 part by weight of polyoxyethylene castor oil and add 1.8 parts by weight of acetonitrile to dissolve it, add 1.8 parts by weight of cyclohexane to extract, stir at 150r / min for 15min, put it in a water bath at 60°C, and let it stand for stratification to obtain the acetonitrile solution of the lower layer; Acetonitrile solution, adding 1.8 parts by weight of cyclohexane for extraction, stirring at 150r / min for 15min, standing in a water bath at 30°C, standing for stratification to obtain the lower layer of acetonitrile solution; repeating the extraction with cyclohexane for 3 times, the final acetonitrile extract in In a water bath at 60°C, remove acetonitrile by rotary evaporation to obtain refined polyoxyethylene castor oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com