Method for synthesizing Cu-ZIF-67 by doping copper into zeolite-imidazolium framework

A zeolite imidazolium salt, cu-zif-67 technology, applied in the field of ZIF-67 synthesis, can solve problems such as low gas separation performance, affecting gas molecule transport, etc., achieve excellent thermal stability, reduce pollution, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

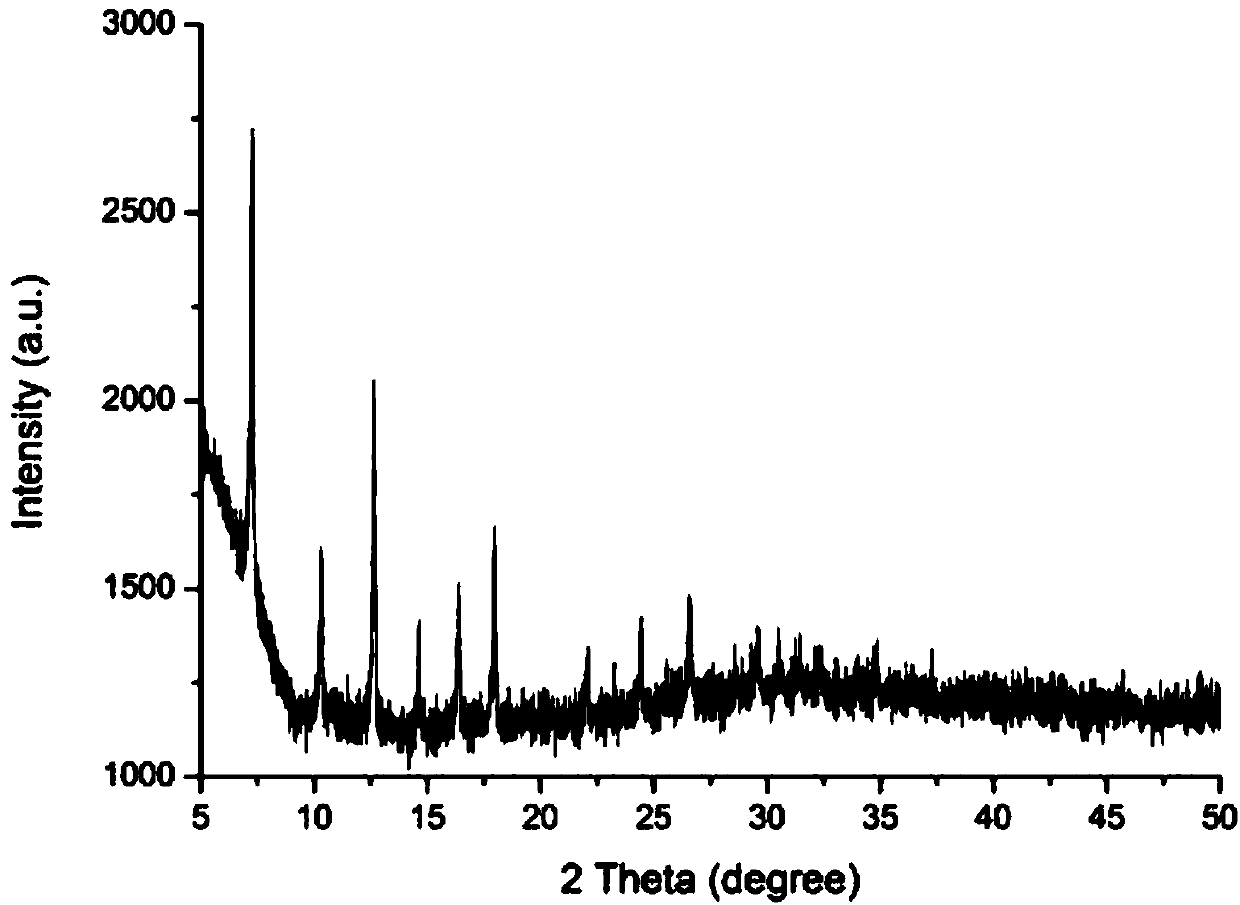

[0026] Embodiment one: the Cu(NO of 0.51g 3 ) 2 ·3H 2 O and 0.95g of Co(NO 3 ) 2 ·6H 2 O mixed, added 8ml deionized water, stirred and dissolved to obtain mixed solution A. Mix 23.22g of 2-methylimidazole (HmIm) and 80ml of deionized water, and continue stirring to dissolve to obtain mixed solution B. The mixed solution A and the mixed solution B were mixed and stirred for 60 minutes to obtain a homogeneous gel, and the homogeneous gel was centrifuged to separate the mother liquor, wherein the rotation speed was 7000 rpm, and the centrifugation time was 60 minutes. The solid sample collected after centrifugation was washed with deionized water, and then heated in an oven at 100°C for 12h, and the final product was Cu5-ZIF-67, figure 1 is the XRD pattern of the Cu5-ZIF-67.

Embodiment 2

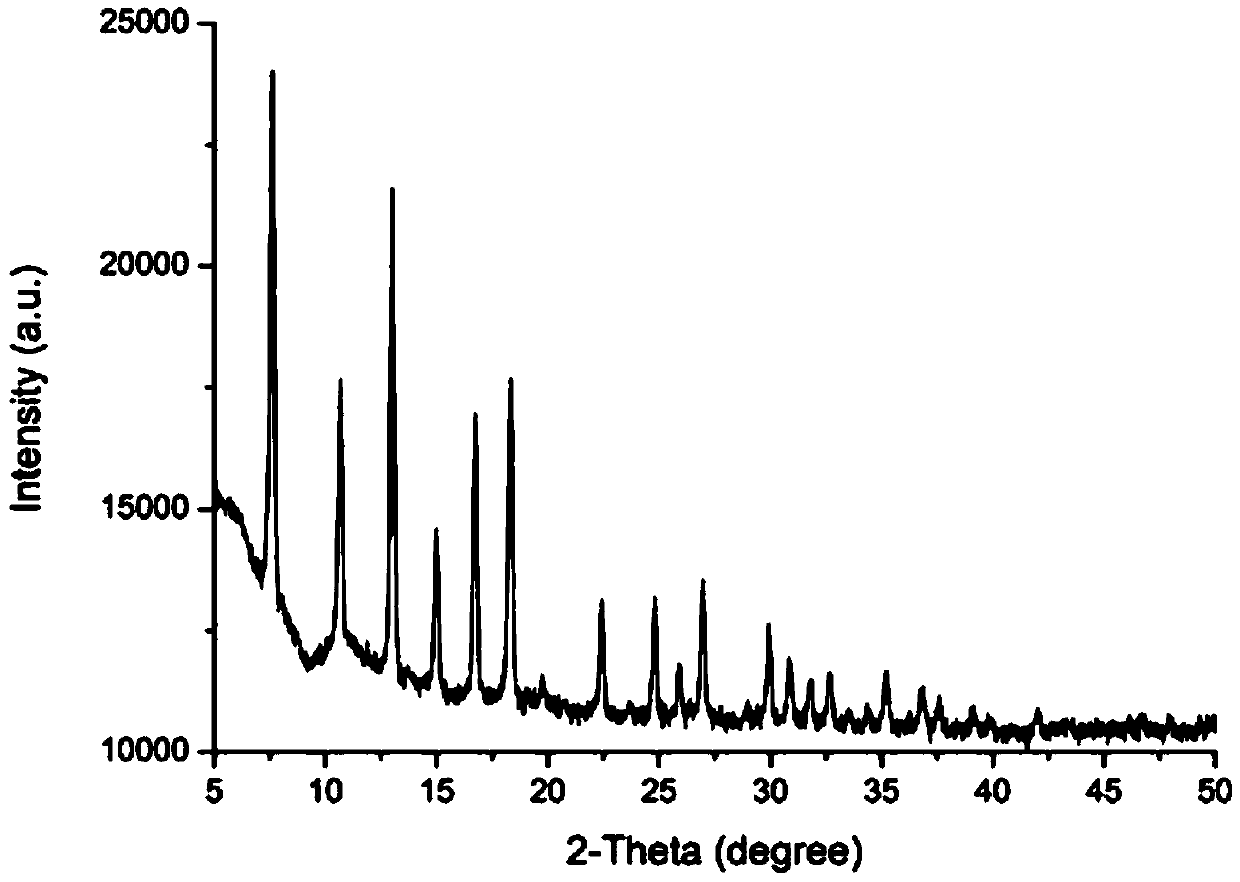

[0027] Embodiment two: the Cu(NO of 0.15g 3 ) 2 ·3H 2 O and 0.95g of Co(NO 3 ) 2 ·6H 2 O mixed, added 8ml deionized water, stirred and dissolved to obtain mixed solution A. 11.62 g of 2-methylimidazole (HmIm) and 40 ml of deionized water were mixed and continuously stirred to dissolve to obtain a mixed solution B. The mixed solution A and the mixed solution B were mixed and stirred for 60 minutes to obtain a homogeneous gel, and the homogeneous gel was centrifuged to separate the mother liquor, wherein the rotation speed was 9000 rpm, and the centrifugation time was 80 minutes. The solid sample collected after centrifugation was washed with deionized water, and then heated in an oven at 100°C for 24h, and the final product was Cu15-ZIF-67, figure 2 is the XRD pattern of the Cu15-ZIF-67.

Embodiment 3

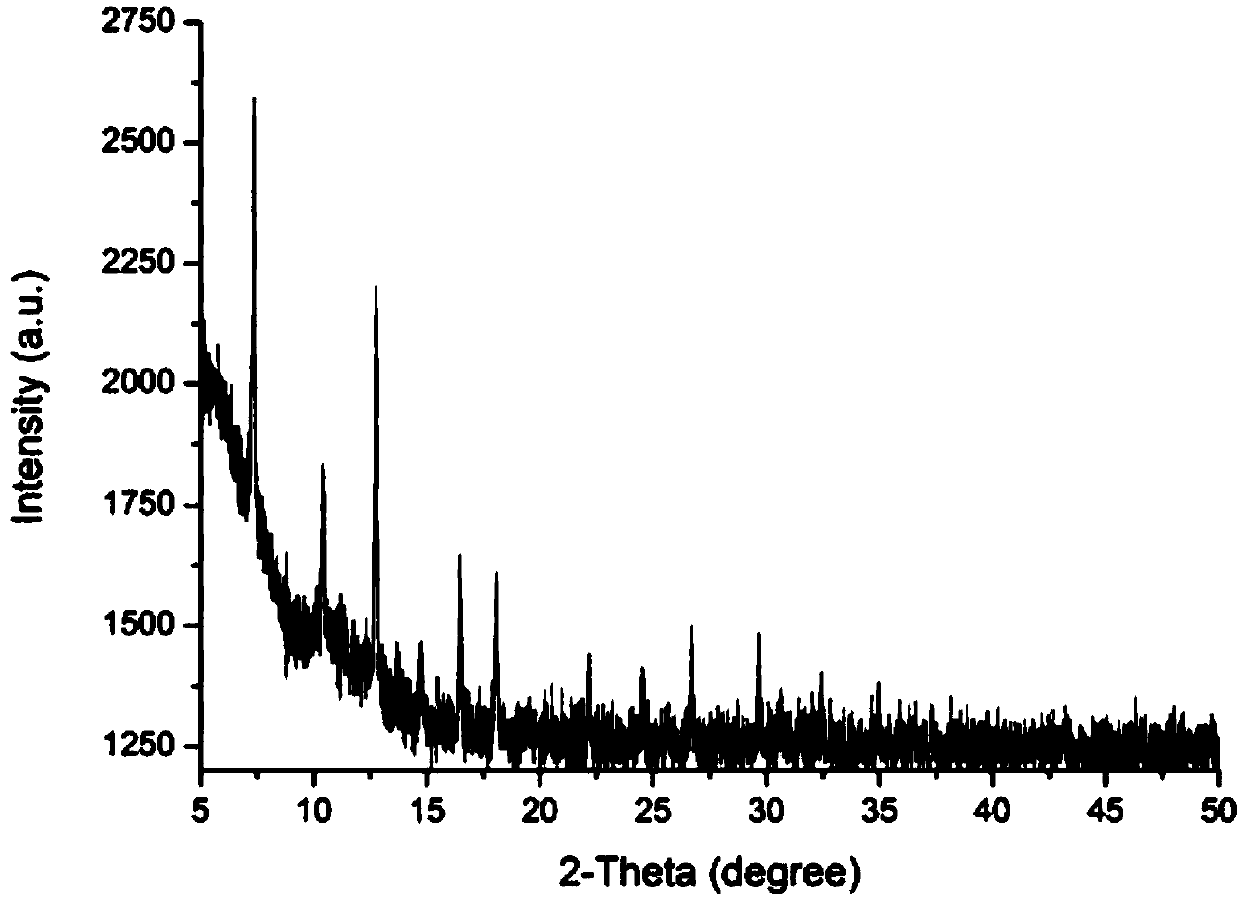

[0028] Embodiment three: the Cu(NO of 0.15g 3 ) 2 ·3H 2 O and 0.95g of Co(NO 3 ) 2 ·6H 2 O mixed, added 4ml deionized water, stirred and dissolved to obtain mixed solution A. Mix 23.22g of 2-methylimidazole (HmIm) with 70ml of deionized water, and continue stirring to dissolve to obtain mixed solution B. The mixed solution A and the mixed solution B were mixed and stirred for 5 minutes to obtain a homogeneous gel, and the homogeneous gel was centrifuged to separate the mother liquor, wherein the rotation speed was 12000 rpm, and the centrifugation time was 70 minutes. The solid sample collected after centrifugation was washed with deionized water, and then heated in an oven at 100°C for 12h, and the final product was Cu15-ZIF-67, image 3 is the XRD pattern of the Cu15-ZIF-67. Because the mixing and stirring time of the solution of this embodiment is shorter, the output of synthesis is less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com