Fertilizer for improving saline-alkali soil

A technology for improving fertilizer and saline-alkali land, applied in the direction of nitrogen fertilizer, potassium fertilizer, phosphorus fertilizer, etc., can solve the problems of crop disease, slow release, insufficient fermentation, etc., to kill pathogenic bacteria and parasite eggs, increase organic matter transformation, and increase reproduction number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

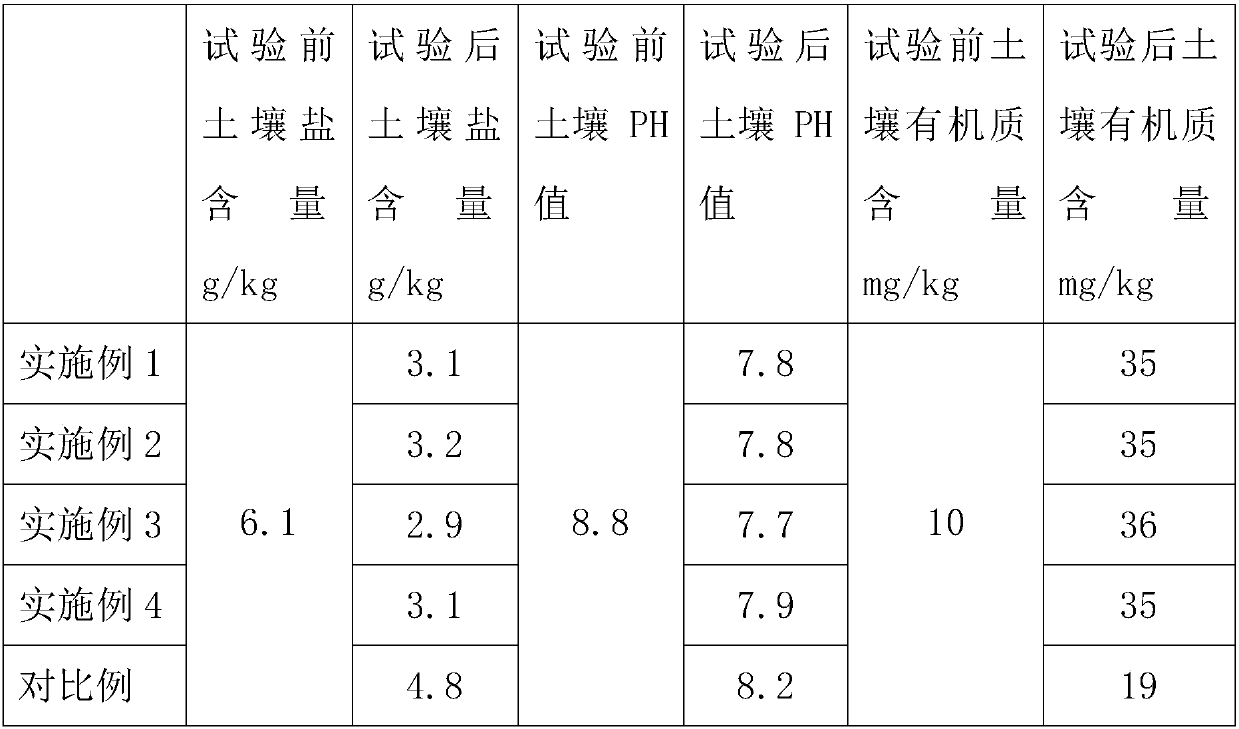

Examples

Embodiment 1

[0017] 1) Chopped 28 parts of straw and 25 parts of rotten grass, with a length of 1 cm, and set aside;

[0018] 2) Mix and granulate 15 parts of urea, 13 parts of superphosphate, 7 parts of potassium sulfate and 2 parts of trace elements, and set aside;

[0019] 3) Mix 40 parts of sheep manure with the straw and rotten grass prepared in step 1), add distilled water to 0.1 part of microbial inoculum for dilution, the volume ratio of microbial inoculum to distilled water is 1:200, and dilute the diluted The microbial agent is evenly sprayed on the mixture, and then 6 parts of corn flour are added to the mixture for composting and fermentation. The fraction is 8%-20%, and the fermentation time is 8 days;

[0020] 4) Mix the fertilizer granules prepared in step 2) and the fermented fertilizer prepared in step 3) evenly, and apply them to saline-alkali soil.

Embodiment 2

[0022] 1) Chopped 31 parts of straw and 27 parts of rotten grass, the length is 2cm, set aside;

[0023] 2) Mix and granulate 17 parts of urea, 15 parts of superphosphate, 9 parts of potassium sulfate and 3 parts of trace elements, and set aside;

[0024] 3) Mix 43 parts of cow dung with the straw and rotten grass prepared in step 1), add distilled water to 0.2 parts of microbial inoculum for dilution, the volume ratio of microbial inoculum to distilled water is 1:200, and dilute the diluted The microbial agent is evenly sprayed on the mixture, and then 9 parts of corn flour are added to the mixture for composting and fermentation. The fraction is 8% to 20%, and the fermentation time is 10 days;

[0025] 4) Mix the fertilizer granules prepared in step 2) and the fermented fertilizer prepared in step 3) evenly, and apply them to saline-alkali soil.

Embodiment 3

[0027] 1) Chopped 34 parts of straw and 30 parts of rotten grass, the length is 2cm, set aside;

[0028] 2) 18 parts of urea, 16 parts of superphosphate, 12 parts of potassium sulfate and 4 parts of trace elements are mixed and granulated, and set aside;

[0029] 3) Mix 47 parts of pig manure with the straw and rotten grass prepared in step 1), add distilled water to 0.2 parts of microbial inoculum for dilution, the volume ratio of microbial inoculum to distilled water is 1:200, and dilute the diluted The microbial agent is evenly sprayed on the mixture, and then 12 parts of corn flour are added to the mixture for composting and fermentation. The fraction is 8% to 20%, and the fermentation time is 12 days;

[0030] 4) Mix the fertilizer granules prepared in step 2) and the fermented fertilizer prepared in step 3) evenly, and apply them to saline-alkali soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com