Bio-based degradable polyester fiber and preparation method thereof

A technology for degrading polyester and bio-based, applied in the direction of single-component polyetherester rayon, melt spinning, stretch spinning, etc., can solve the spinning processing requirements and processing difficulties, and the low viscosity of polyester materials cannot meet and other problems to achieve the effect of enhancing biodegradable performance, increasing hydrophilic performance and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

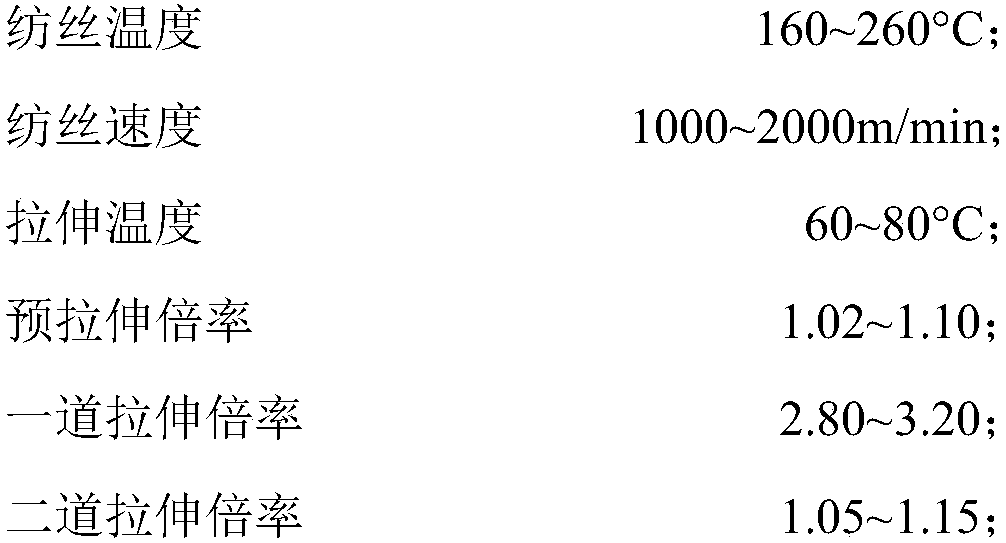

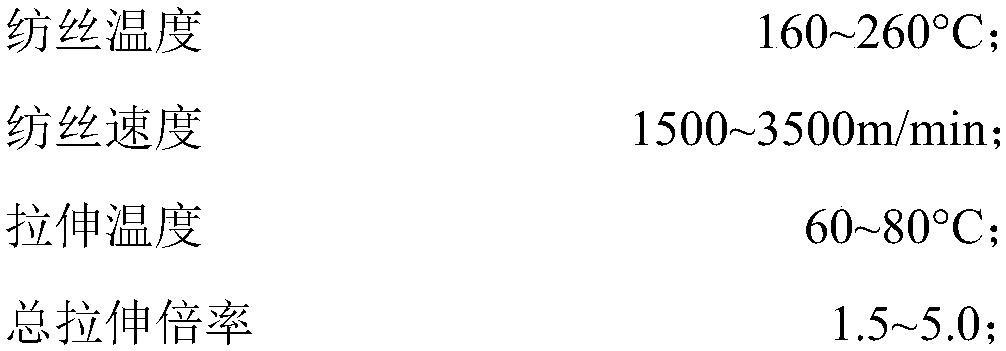

Embodiment 1

[0063] A preparation method of bio-based degradable polyester staple fiber, the specific steps are as follows:

[0064] (1) Esterification reaction;

[0065] Mix 1,2-propanediol, 1,2-butanedioic acid and tetrabutyl titanate evenly, then carry out esterification reaction until the esterification rate is 92% to obtain an esterified product; 1,2-propanediol and 1,2-butanediol The molar ratio when the acids are mixed is 1.2:1.0, the added amount of tetrabutyl titanate is 150ppm of the added amount of 1,2-butanedioic acid, the temperature of the esterification reaction is 200°C, and the pressure is 0.3MPa;

[0066] (2) Segmented precondensation reaction;

[0067] (2.1) the first precondensation reaction, add polyethylene glycol to the esterified product of step (1) and carry out the first precondensed reaction after mixing; the molar ratio of polyethylene glycol and esterified compound is 0.5:1.0 , the temperature of the first precondensation reaction is 220°C, the pressure is 0....

Embodiment 2

[0079] A preparation method of bio-based degradable polyester staple fiber, the specific steps are as follows:

[0080] (1) Esterification reaction;

[0081] Mix 1,2-pentanediol, 1,4-pentanedioic acid and tetrabutyl titanate uniformly and carry out esterification reaction until the esterification rate is 92% to obtain an esterified product; 1,2-pentanediol and 1, The molar ratio when mixing 4-glutaric acid is 1.2:1.0, the amount of tetrabutyl titanate added is 150ppm of the added amount of 1,4-glutaric acid, the temperature of the esterification reaction is 240°C, and the pressure is 0.3MPa ;

[0082] (2) Segmented precondensation reaction;

[0083] (2.1) the first precondensation reaction, add polyethylene glycol to the esterified product of step (1) and carry out the first precondensed reaction after mixing; the molar ratio of polyethylene glycol and esterified compound is 0.5:1.0 , the temperature of the first precondensation reaction is 220°C, the pressure is 0.1MPa, an...

Embodiment 3

[0092] A preparation method of bio-based degradable polyester staple fiber, the specific steps are as follows:

[0093] (1) Esterification reaction;

[0094] Mix 1,3-pentanediol, 1,5-pentanedioic acid and tetrabutyl titanate uniformly, then carry out esterification reaction until the esterification rate is 92% to obtain an esterified product; 1,3-pentanediol and 1, The molar ratio when mixing 5-glutaric acid is 1.2:1.0, the amount of tetrabutyl titanate added is 150ppm of the added amount of 1,5-glutaric acid, the temperature of the esterification reaction is 240°C, and the pressure is 0.3MPa ;

[0095] (2) Segmented precondensation reaction;

[0096] (2.1) the first precondensation reaction, add polyethylene glycol to the esterified product of step (1) and carry out the first precondensed reaction after mixing; the molar ratio of polyethylene glycol and esterified compound is 0.5:1.0 , the temperature of the first precondensation reaction is 220°C, the pressure is 0.1MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com