Wood adhesive and preparation method thereof

A technology of wood adhesives and additives, applied in the direction of adhesive additives, monocarboxylate copolymer adhesives, adhesive types, etc., can solve toughness, poor freeze-thaw resistance stability, and adhesive layer strength Great impact, speed up the side reaction rate and other issues, to achieve the effect of improving storage stability, good product stability, and good resistance to thawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

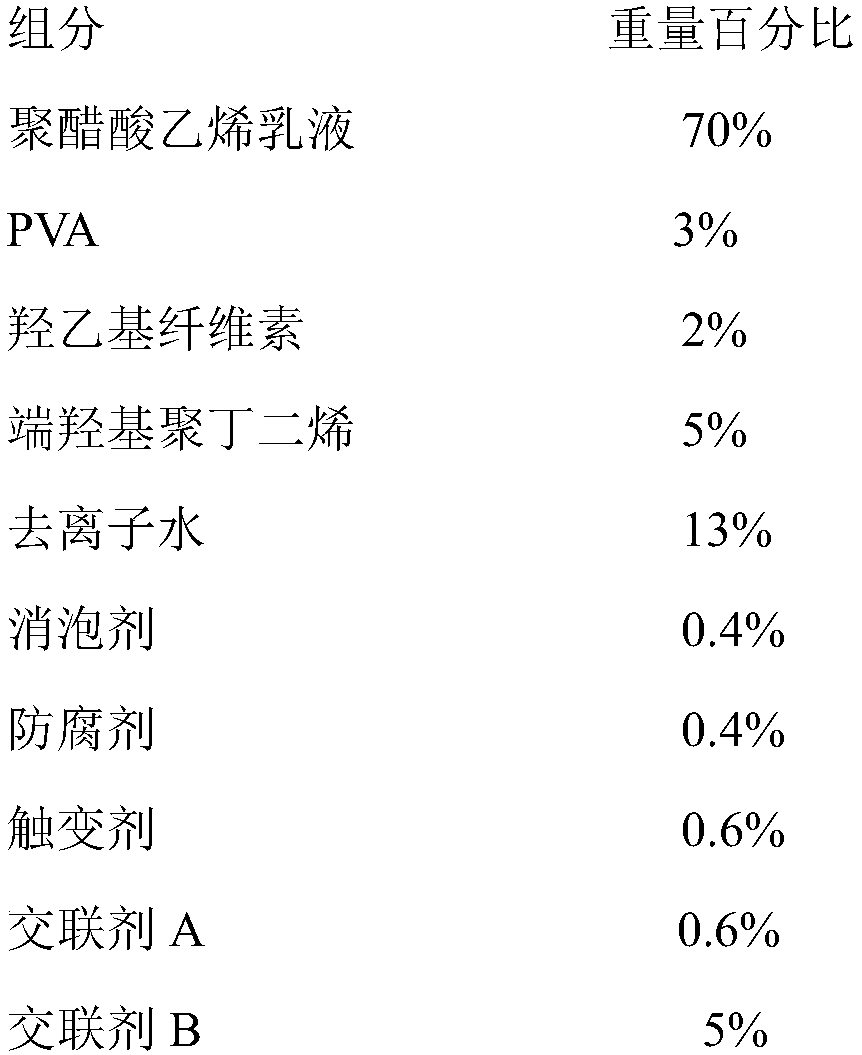

Embodiment 1

[0043]

[0044] The above raw materials are commercially available, wherein the defoamer is mineral oil, the preservative is benzoxazolones, the thixotropic agent is fumed silica, and the cross-linking agent A is polymethylene phenyl isocyanate. Agent B is polymethylene polyphenylisocyanate.

[0045] Weigh the raw materials according to the above weight ratio, add deionized water into the reactor, slowly add defoamer, hydroxyl-terminated polybutadiene, PVA at a stirring rate of 100r / min, keep the stirring rate constant, and raise the temperature to 80 ℃, slowly add hydroxyethyl cellulose and cross-linking agent A, then stir at constant temperature and speed for 2 hours, then lower the temperature to 60°C, add polyvinyl acetate emulsion, stir for 30 min at a stirring speed of 500r / min, and slowly add cross-linking agent B. Stir for 2 hours, then add thixotropic agent and preservative, stir for 1 hour at a stirring rate of 800r / min, take samples for inspection, filter, and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com