Phaseolin polypeptide preparation method and obtained phaseolin polypeptide

A protein polypeptide and conditional technology, which is applied in the field of protein polypeptide and protein polypeptide preparation, can solve the problems of uncontrollable hydrolysis degree, unfavorable absorption and utilization, amino acid destruction, etc., and achieve the effect of short preparation time, easy control and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

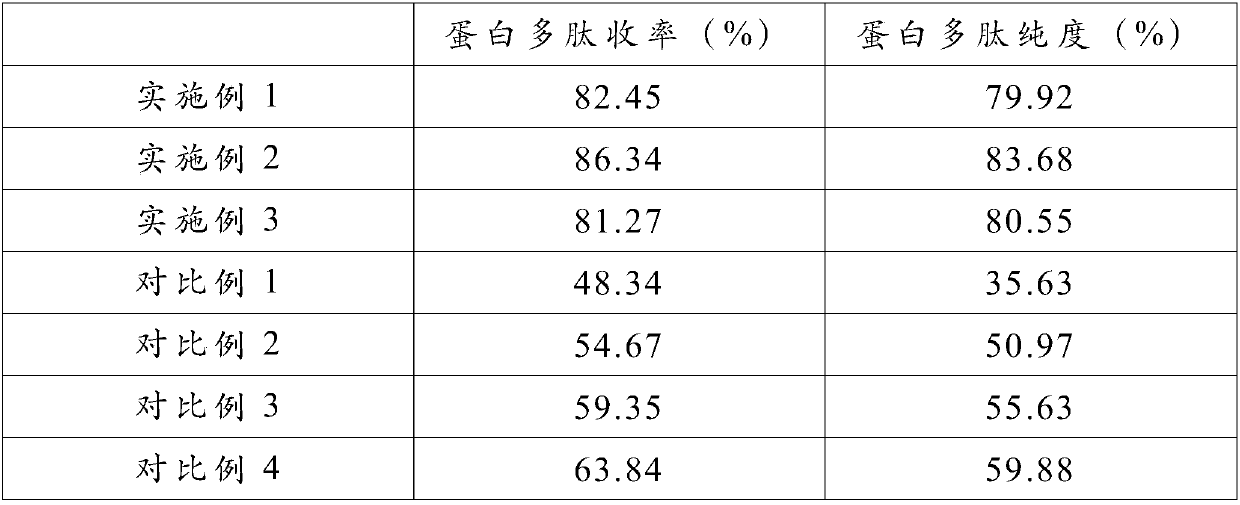

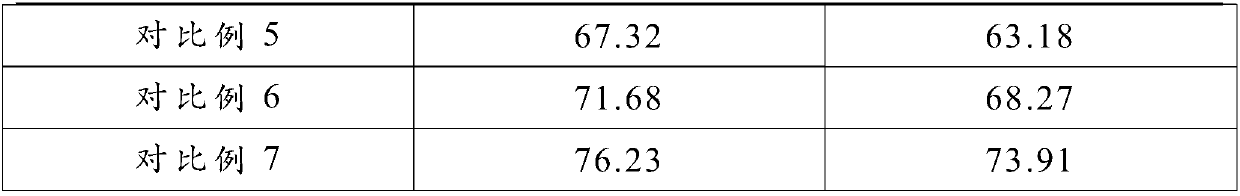

Examples

Embodiment 1

[0032] Embodiment 1, the preparation of a kind of protein polypeptide

[0033] Step 1. Grinding 10 parts of oysters, 15 parts of deer blood, 6 parts of leeches and 30 parts of water to obtain a mixed slurry;

[0034] Step 2, pass AC current into the mixed solution obtained in Step 1, the frequency of the AC current is 8200Hz, the voltage is 2000V, process for 8min, cut off the power supply, then after 20min by constant voltage reverse current treatment, the constant voltage The voltage of the reverse current is 500V, and the constant voltage forward current is passed through for 16min, and the voltage of the constant voltage forward current is 500V to obtain the mixed solution I;

[0035] Step 3, place the mixed solution I obtained in step 1 at room temperature and stir for 20min, then add elastase, the addition of the elastase is 0.3‰ of the total weight of the mixed solution I, and after 1h under neutral greenhouse conditions, heat up to Inactivate the enzyme at 75°C, centr...

Embodiment 2

[0038] Embodiment 2, the preparation of a kind of protein polypeptide

[0039] Step 1, grinding 16 parts of oysters, 15 parts of deer blood, 8 parts of leeches and 35 parts of water to obtain a mixed slurry;

[0040] Step 2, pass AC current into the mixed solution obtained in Step 1, the frequency of the AC current is 9000Hz, the voltage is 2500V, process for 6min, cut off the power supply, then after 15min by constant voltage reverse current treatment, the constant voltage The voltage of the reverse current is 530V, and the constant voltage forward current is passed through for 10min, and the voltage of the constant voltage forward current is 530V to obtain the mixed solution I;

[0041] Step 3, place the mixed solution I obtained in step 1 at room temperature and stir for 25 minutes, then add elastase, the amount of elastase added is 0.5‰ of the total weight of the mixed solution I, after 1.5h under neutral greenhouse conditions, heat up Inactivate the enzyme at 90°C, centr...

Embodiment 3

[0044] Embodiment 3, the preparation of a kind of protein polypeptide

[0045] Step 1, grinding 20 parts of oysters, 15 parts of deer blood, 10 parts of leeches and 40 parts of water to obtain a mixed slurry;

[0046] Step 2, pass AC current into the mixed solution obtained in Step 1, the frequency of the AC current is 9500Hz, the voltage is 3000V, process for 4min, cut off the power supply, then after 10min by constant voltage reverse current treatment, the constant voltage The voltage of the reverse current is 600V, and the constant voltage forward current is passed through for 16 minutes, and the voltage of the constant voltage forward current is 600V to obtain the mixed solution I;

[0047] Step 3, place the mixed solution I obtained in step 1 at room temperature and stir for 30 minutes, then add elastase, the addition of the elastase is 0.8‰ of the total weight of the mixed solution I, and after 2 hours under neutral greenhouse conditions, heat up to Inactivate the enzyme ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com