A kind of gauze for purifying air and preparation method thereof

A technology for purifying air and gauze, which is applied in the field of air purification, can solve the problems of power consumption, insufficient low-carbon environmental protection, and large volume, and achieve the effect of improving purification capacity and excellent purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

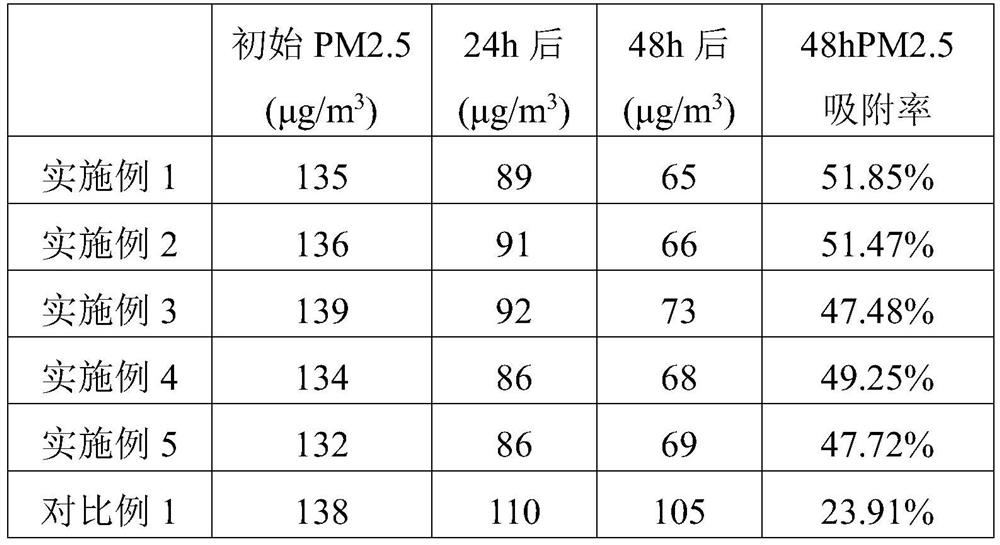

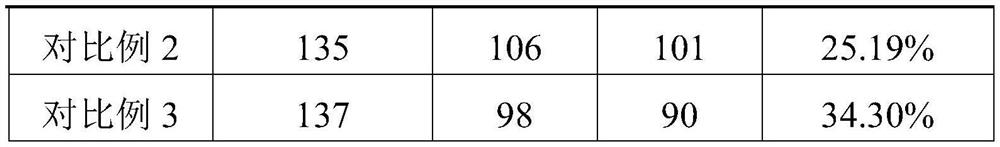

Examples

Embodiment 1

[0051] A preparation method of a gauze for purifying air:

[0052] (1) Disperse polyvinylidene fluoride emulsion and activated carbon fiber (manufactured by Nantong Xintong Activated Carbon Fiber Co., Ltd.) added with sodium bicarbonate in N,N-dimethylformamide solvent, and ultrasonically disperse at a power of 500kw for 10min , to obtain the emulsion mixture;

[0053] Carry out electrospinning to the emulsion mixture, the process of described electrospinning is: power supply voltage control is 30KV, the ambient temperature of spinning is 25 ℃, and relative humidity is 60%RH; The number of needles in the spinning unit is 50; obtain the precursor;

[0054] (2) Mix silver nitrate and polyvinylidene fluoride emulsion in N,N-dimethylformamide solvent evenly to form an impregnating liquid, immerse the raw silk in step (1) in the impregnating liquid for 4 hours, and soak in the original silk A homogeneous fiber wall is formed on the surface to form composite spinning;

[0055] (3...

Embodiment 2

[0060] A preparation method of a gauze for purifying air:

[0061] (1) Disperse the polybutylene terephthalate emulsion and activated carbon fiber added with 4,4-oxobisbenzenesulfonyl hydrazide in dichloromethane solvent, and ultrasonically disperse for 10 minutes at a power of 500kw to obtain an emulsion mixture ;

[0062] Carry out electrospinning to the emulsion mixture, the process of described electrospinning is: power supply voltage control is 25KV, and the ambient temperature of spinning is 23 ℃, and relative humidity is 45%RH; The number of needles in the spinning unit is 30; obtain the precursor;

[0063] (2) Mix silver fluoride and polybutylene terephthalate emulsion in dichloromethane solvent to form an impregnating solution, immerse the precursor in step (1) in the impregnating solution for 4 hours, and place it on the surface of the precursor Form a homogeneous fiber wall to form composite spinning;

[0064] (3) The composite spinning in the step (2) is woven i...

Embodiment 3

[0069] A preparation method of a gauze for purifying air:

[0070] (1) Disperse polyethylene terephthalate emulsion and activated carbon fiber added with azodicarbonamide in dichloromethane solvent, and ultrasonically disperse for 10min at a power of 500kw to obtain an emulsion mixture;

[0071] Carry out electrospinning to the emulsion mixture, the process of described electrospinning is: the power supply voltage is controlled to 50KV, the ambient temperature of spinning is 27 ℃, the relative humidity is 70%RH; The needle head quantity of silk unit is 70; Obtain precursor silk;

[0072] (2) Silver sulfate and polyethylene terephthalate emulsion are mixed uniformly in dichloromethane solvent to form an impregnating solution, and the precursor in step (1) is immersed in the impregnating solution for 4 hours to form on the surface of the precursor Homogeneous fiber wall, forming composite spinning;

[0073] (3) The composite spinning in the step (2) is woven into a plain weave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com