Purification method of plant endogenous brassinolide based on boron affinity solid phase extraction

A technology of brassinosteroids and boron affinity, applied in the field of analytical chemistry, can solve the problems of affecting derivatization efficiency, lower sensitivity, low recovery rate, etc., and achieve the effects of easy operation, reduced sample usage, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

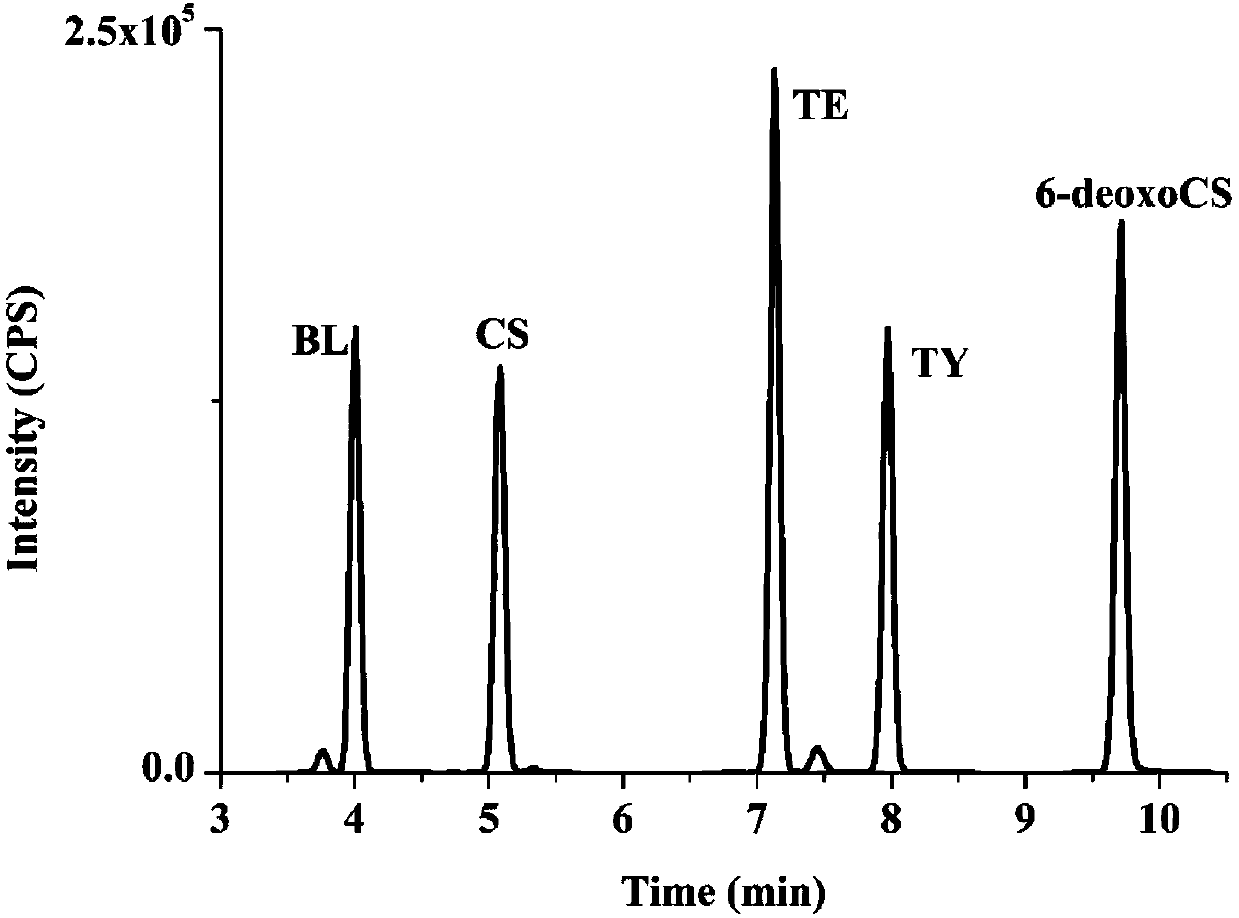

[0044] Example 1, Determination of Brassinolide in Paddy Nipponbare Flowering Stage Ear

[0045] Weigh 10 mg of the ground plant sample (wild-type rice Nipponbare flowering stage panicle) and put it into a 2 mL centrifuge tube, add 1 mL of an aqueous methanol solution with a concentration of 60% extraction solvent by mass, then add 25-100 pg of a stable isotope internal standard, and mix well . Ultrasonic extraction at room temperature for 1 h. The supernatant was obtained by centrifugation, and the supernatant was loaded onto a boron affinity solid-phase extraction column (1CC, 100mg, BondElut PBA, Agilent). 5% methanol solution of formic acid, methanol and water rinse the solid phase extraction column in sequence, then use 5% hydrogen peroxide to oxidize the complex formed by the combination of BRs and boron affinity material, and then use 5% ammonia solution to hydrolyze the oxidation product, After rinsing with water to remove the generated boric acid, BRs was finally elut...

Embodiment 2

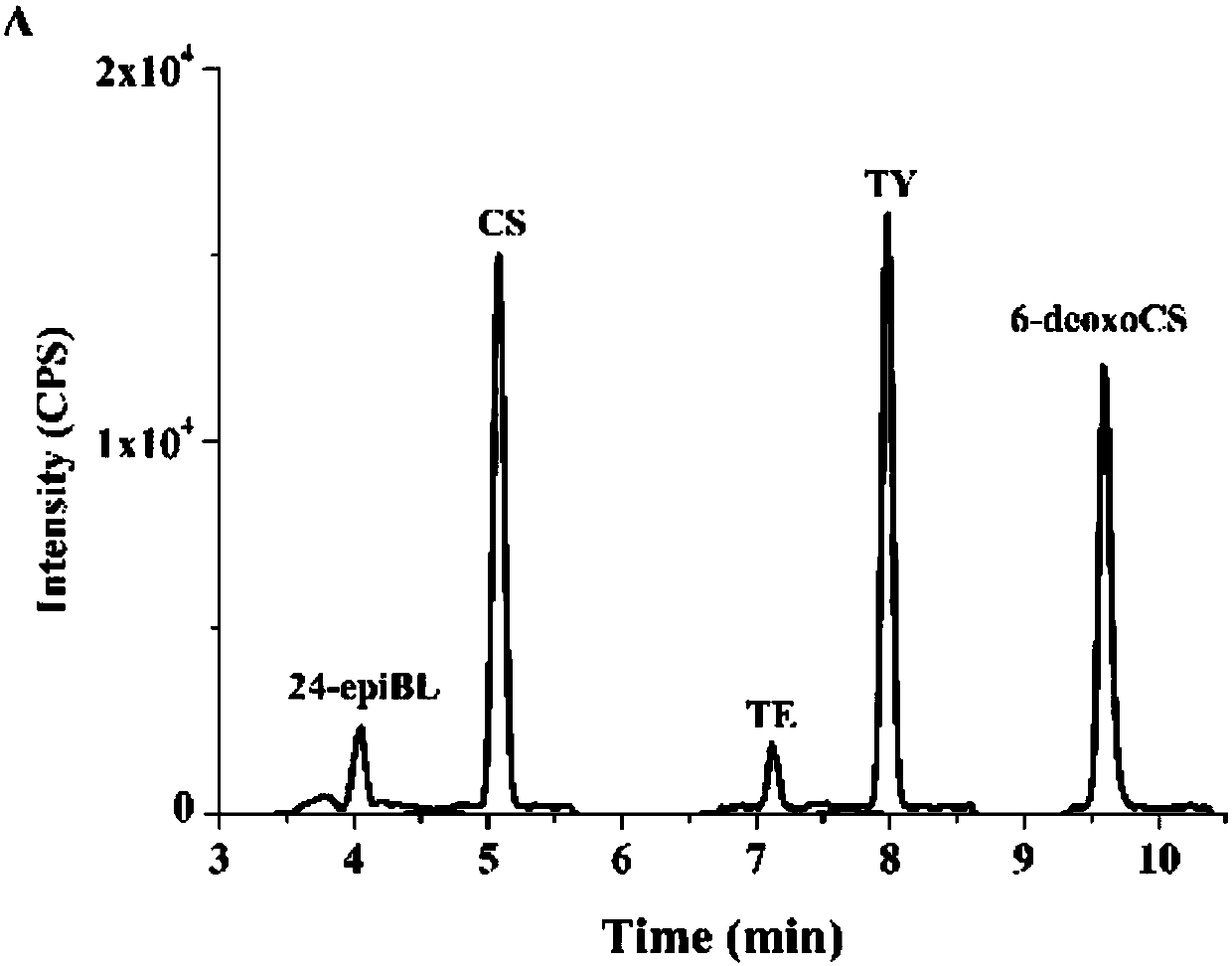

[0046] Example 2, Determination of Brassinolide in Rice Nipponbare Leaves

[0047] Weigh 10 mg of the ground plant sample (rice Nipponbare leaf) into a 2 mL centrifuge tube, add 1 mL of 80% methanol, then add 25-100 pg of stable isotope internal standard, and mix well. Ultrasonic extraction at room temperature for 1 h. Centrifuge to get the supernatant, and interact the supernatant with a boron affinity solid-phase extraction column (1CC, 100mg, Bond Elut PBA, Agilent), and use a formic acid aqueous solution with a mass percent concentration of 5%, and a formic acid mass percent concentration of 5% methanol solution of formic acid, methanol and water rinse the solid phase extraction column in sequence, then use 10% hydrogen peroxide to oxidize the complex formed by the combination of BRs and boron affinity material, and then use 10% ammonia solution to hydrolyze the oxidation product, After rinsing with water to remove the generated boric acid, BRs was finally eluted in rever...

Embodiment 3

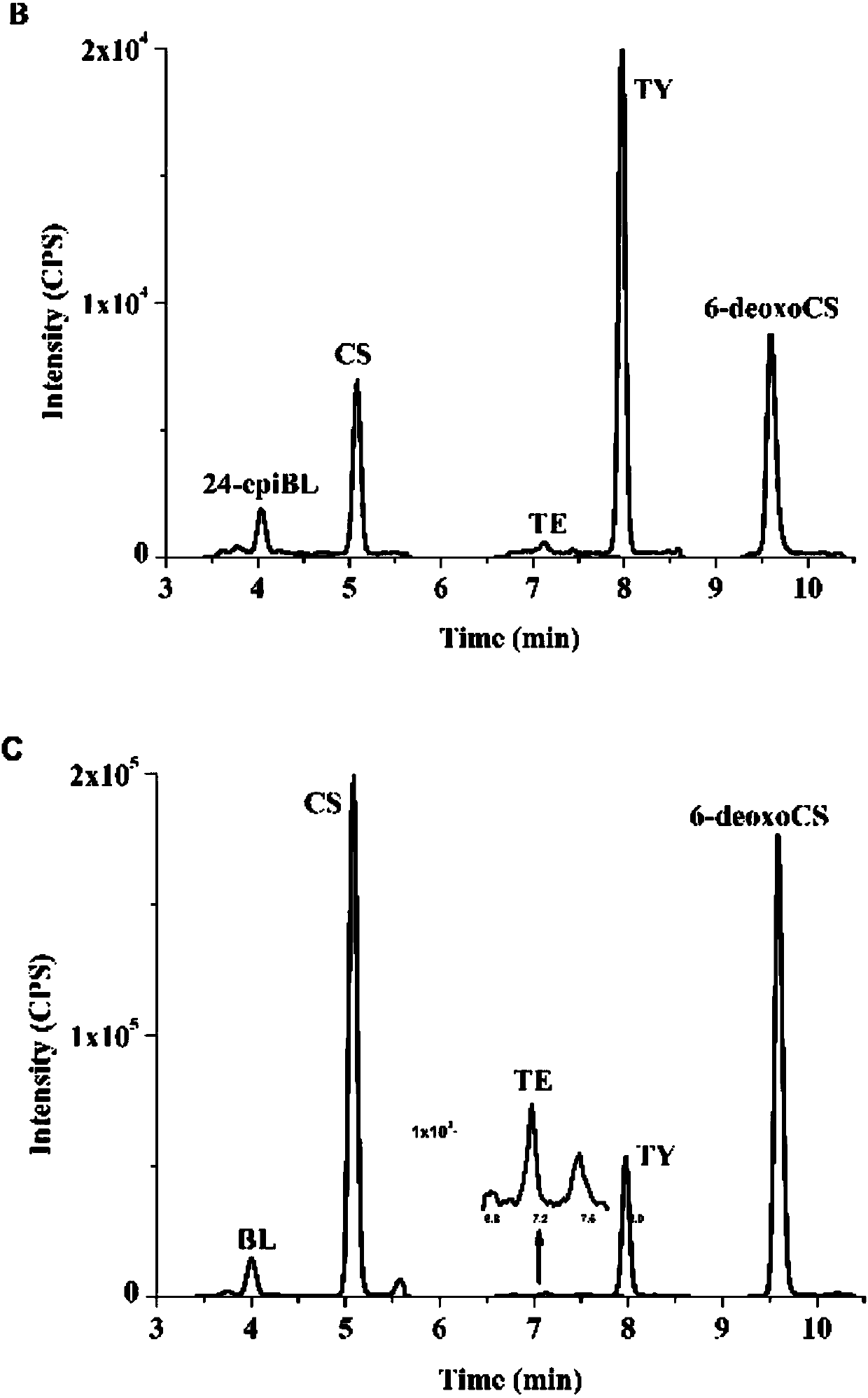

[0048] Embodiment 3, the mensuration of brassinolide in rice Nipponbare stem

[0049] Weigh 10 mg of the ground plant sample (rice Nipponbare stem) into a 2 mL centrifuge tube, add 1 mL of methanol, then add 25-100 pg of stable isotope internal standard, and mix well. Ultrasonic extraction at room temperature for 1 h. Centrifuge to take the supernatant, and interact the supernatant with 5 mg of boron-affinity material (Benzeneboronic acid, polymer-supported, boronic acid group content 2.6-3.2mmol / g, Alfa Aesar) dispersed in solid phase extraction, expressed in mass percent Concentration is 5% formic acid aqueous solution, formic acid mass percent concentration is 5% formic acid methanol solution, methanol and water rinse the solid phase extraction column successively, then use 5% ammonia solution containing 5% hydrogen peroxide to oxidatively hydrolyze BRs and The complex formed by the combination of the boron affinity material was washed with water to remove the generated bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com