Filter net with formaldehyde purification function and preparation method of filter net

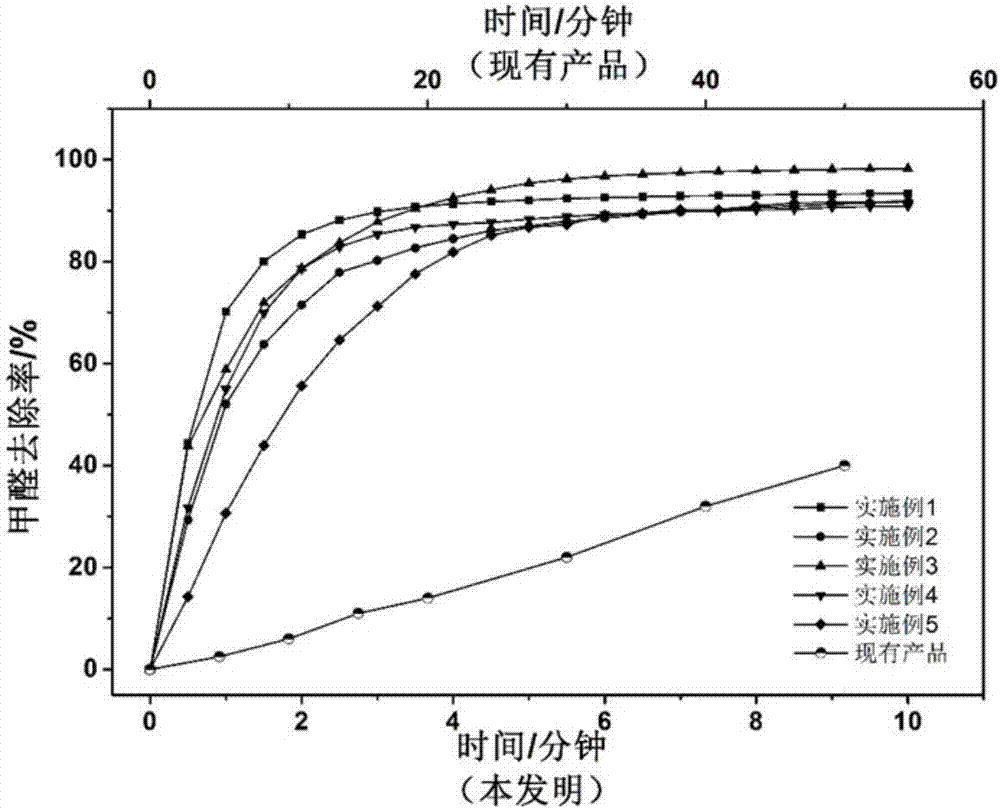

A formaldehyde purification and filter screen technology, applied in the field of air purification, can solve the problems of low efficiency of adsorption-type air purifiers, weak formaldehyde filtration effect, and unsatisfactory effects, achieve excellent aerodynamic performance, and enhance the removal of formaldehyde. The effect of small capacity and wind resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of a filter screen with formaldehyde purification function.

[0037] 1) Add 2g of polyvinylpyrrolidone and 1g of polyethylene glycol into 500g of deionized water, and dissolve with mechanical stirring at 85°C to obtain solution A;

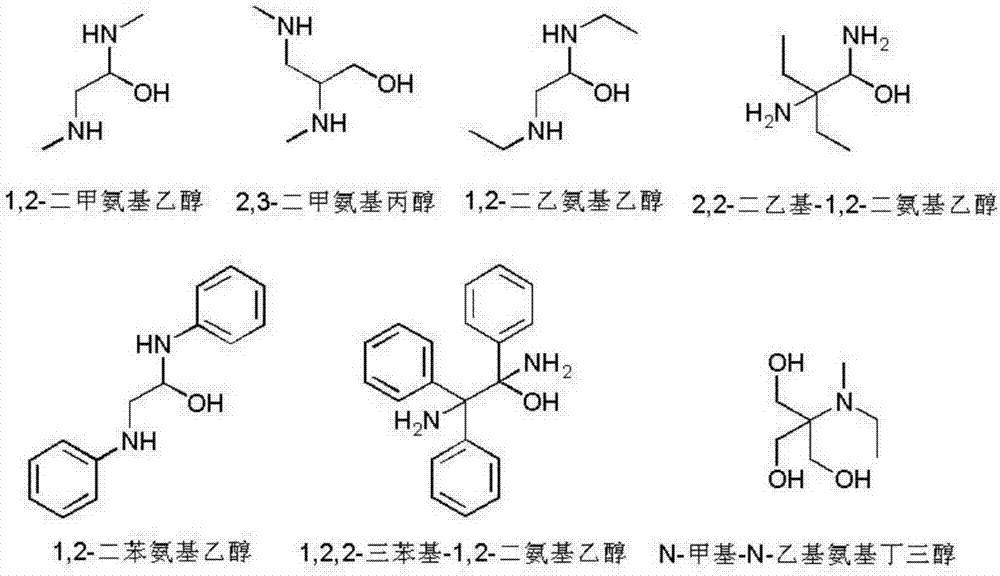

[0038] 2) Mix 1g of titanium dioxide, 1g of tin dioxide, 1g of silicon dioxide, 2g of magnesium oxide, 1g of activated carbon, 1g of calcium chloride, 1g of sodium carbonate and 4g of 1,2-dimethylaminoethanol to obtain mixture B;

[0039] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of mechanical stirring to obtain mixture C, which is filtered through a 200-mesh filter to obtain a formaldehyde purification composite material;

[0040]4) The aluminum honeycomb is placed in the formaldehyde purification composite material obtained in step 3), and the formaldehyde purification composite material is attached to the surface of the aluminum honeycomb by dippi...

Embodiment 2

[0042] Example 2: Preparation of a filter screen with formaldehyde purification function.

[0043] 1) Add 10g of polyvinylpyrrolidone and 6g of polyacrylamide into 800g of absolute ethanol, and dissolve with mechanical stirring at 60°C to obtain solution A;

[0044] 2) Mix 5.5g of titanium dioxide, 5.5g of tin dioxide, 4g of silicon dioxide, 6g of magnesium oxide, 30g of activated carbon, 7g of calcium chloride, 9g of sodium bicarbonate, 20g of 2,3-dimethylaminopropanol and 22g of 1,2- Diethylaminoethanol is mixed to obtain mixture B;

[0045] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of mechanical stirring to obtain mixture C, which is filtered through a 300-mesh filter to obtain a formaldehyde purification composite material;

[0046] 4) placing the plastic honeycomb in the formaldehyde purification composite material obtained in step 3), and attaching the formaldehyde purification composite material to the ...

Embodiment 3

[0048] Example 3: Preparation of a filter screen with formaldehyde purification function.

[0049] 1) Add 4g of polyvinylpyrrolidone and 2g of carboxymethyl cellulose into 550g of deionized water, and dissolve with magnetic stirring at 75°C to obtain solution A;

[0050] 2) Mix 2g of titanium dioxide, 2g of tin dioxide, 1g of silicon dioxide, 3g of magnesium oxide, 5g of activated carbon, 2g of calcium chloride, 3g of sodium sulfite and 10g of 1,2-diphenylaminoethanol to obtain mixture B;

[0051] 3) Add the mixture B obtained in step 2) to the solution A obtained in step 1), and disperse evenly by means of magnetic stirring to obtain mixture C, which is filtered through a 200-mesh filter to obtain a formaldehyde purification composite material;

[0052] 4) Adjust the viscosity of the formaldehyde purification composite material obtained in step 3) to 500cps, and spray it on the surface of the paper honeycomb to attach, with a thickness of 0.5mm, to obtain the formaldehyde fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com