A kind of cross-linking agent for imitating reactive pigment printing and preparation method thereof

A pigment printing and imitation activity technology, which is applied in dyeing, textiles and papermaking, etc., can solve the problems of loss of imitation activity of paint, low molecular weight of polyethylene glycol, influence on dry rubbing fastness and printing feel, etc., and achieve dry and wet friction Improvement of fastness and soaping fastness, improvement of water solubility and storage stability, effect of increasing content and crosslinking point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

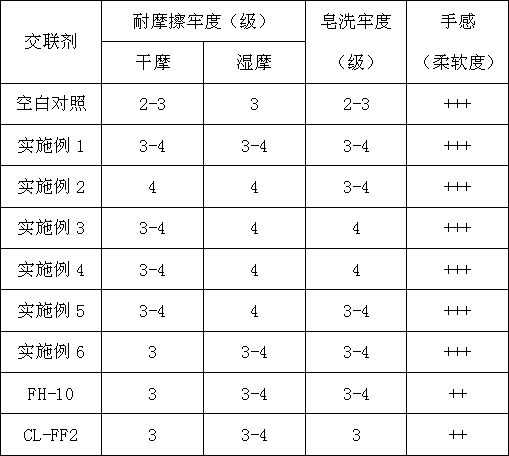

Examples

Embodiment 1

[0027] (1) Under nitrogen protection, mix 70 parts of hexamethylene diisocyanate trimer, 10 parts of polyethylene glycol with a molecular weight of 1000, 2 parts of dimethylolpropionic acid, 1 part of trimethylolpropane, N- Add 30 parts of methylpyrrolidone into the reactor, stir and raise the temperature to 80°C and keep it warm for 2 hours;

[0028] (2) Add 1 part of polyethylene glycol monomethyl ether with a molecular weight of 500, and react at 80° C. for 1.5 hours to obtain a prepolymerized product;

[0029] (3) Lower the temperature of the prepolymerized product to 50°C, add 25 parts of end-capping agent methyl ethyl ketone oxime dropwise, and keep the reaction at 50°C for 3 hours;

[0030] (4) Add 1.5 parts of neutralizing agent triethylamine, react for 20 minutes, add 160 parts of deionized water and stir rapidly to disperse to obtain crosslinking agent emulsion.

Embodiment 2

[0032] (1) Under nitrogen protection, mix 70 parts of hexamethylene diisocyanate trimer, 15 parts of polyethylene glycol with a molecular weight of 2000, 2 parts of dimethylolpropionic acid, 1 part of trimethylolpropane, N- Add 30 parts of methylpyrrolidone into the reactor, stir and raise the temperature to 80°C and keep it warm for 2 hours;

[0033] (2) Add 1.5 parts of polyethylene glycol monomethyl ether with a molecular weight of 500, and react at 85° C. for 1 hour to obtain a prepolymerized product;

[0034] (3) Lower the temperature of the prepolymerization product to 50°C, add 28 parts of end-capping agent methyl ethyl ketone oxime dropwise, and keep the reaction at 50°C for 3 hours;

[0035] (4) Add 1.5 parts of neutralizing agent triethylamine, stir for 20 minutes, add 170 parts of deionized water and stir quickly to disperse to obtain crosslinking agent emulsion.

Embodiment 3

[0037] (1) Under nitrogen protection, mix 80 parts of hexamethylene diisocyanate trimer, 10 parts of polyethylene glycol with a molecular weight of 2000, 3 parts of dimethylolpropionic acid, 1 part of trimethylolpropane, N- Add 40 parts of ethylpyrrolidone into the reactor, stir and raise the temperature to 80°C and keep it warm for 2 hours;

[0038] (2) Add 2 parts of polyethylene glycol monomethyl ether with a molecular weight of 750, and heat-preserve at 85° C. for 1 hour to obtain a prepolymerized product;

[0039] (3) Cool the prepolymerized product to 50°C, add 30 parts of end-capping agent methyl ethyl ketone oxime dropwise, and keep the reaction at 50°C for 3 hours;

[0040] (4) Add 2.3 parts of neutralizing agent triethylamine, stir for 20 minutes, add 190 parts of deionized water and stir quickly to disperse to obtain crosslinking agent emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com