Red fluorescent substance and method for production thereof

A red fluorescent material technology, applied in the field of red fluorescent material, can solve the problems of long decay time and achieve the effects of high emission efficiency, short fluorescence lifetime, and high emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

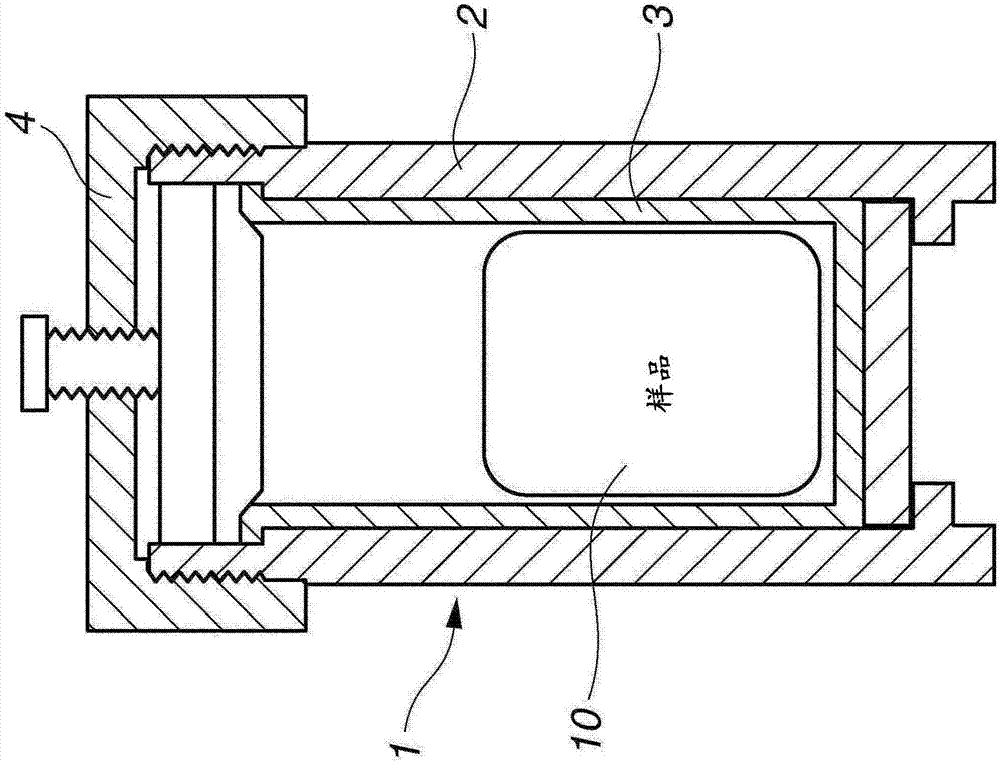

Method used

Image

Examples

Embodiment

[0088] Hereinafter, the present invention will be described in more detail based on Examples and Reference Examples, which are not intended to limit the scope thereof.

reference example 1

[0090] (Preparation K 2 MnF 6 )

[0091] K 2 MnF 6 sample.

[0092] A polyvinyl chloride resin reaction vessel was prepared having two chambers separated by an ion exchange membrane of fluoroplastic placed in the center of the vessel, wherein each chamber was provided with an anode and a cathode, both of which were made of platinum plates. One chamber with the anode is filled with an aqueous solution of hydrofluoric acid containing manganese(II) fluoride dissolved therein. Another chamber with a cathode is filled with an aqueous solution of hydrofluoric acid. Both electrodes were connected to a power supply, and the solution was subjected to electrolysis at a voltage of 3V with a current of 0.75A. After electrolysis, an aqueous solution of hydrofluoric acid saturated with potassium fluoride is supplied in excess to the reaction solution in the chamber with the anode. The resulting reaction product was recovered by filtration as a yellow solid. K 2 MnF6 .

Embodiment 1

[0094] Fill a two liter polyethylene beaker with 232cm 3 40% by weight of fluorotitanic acid (40% H 2 TiF 6 , from MoritaChemical Industries Co., Ltd.), 454cm 3 50% HF (50% high-purity hydrofluoric acid, semiconductor grade (SA grade), from Stella Chemifa Corporation) and 570cm 3 Pure water to start the first step. After stirring and mixing, a solution was obtained, which was named the first solution. The next step involved filling a one-liter polyethylene beaker (which had been placed in a water bath with ice) with 720 g (407 cm 3 ) Aqueous cesium hydroxide solution (comprising 50% by weight of CsOH from Nihon Kagaku Sangyo Co., Ltd.). Further fill the beaker with stirring to 248cm 3 water, then fill it into 89cm little by little 3 50% HF. After continued stirring and cooling, a solution was obtained, which was named the second solution. 11.9 g of K prepared in Reference Example 1 were provided to the first solution 2 MnF 6 (powder form), stir to complete dissoluti...

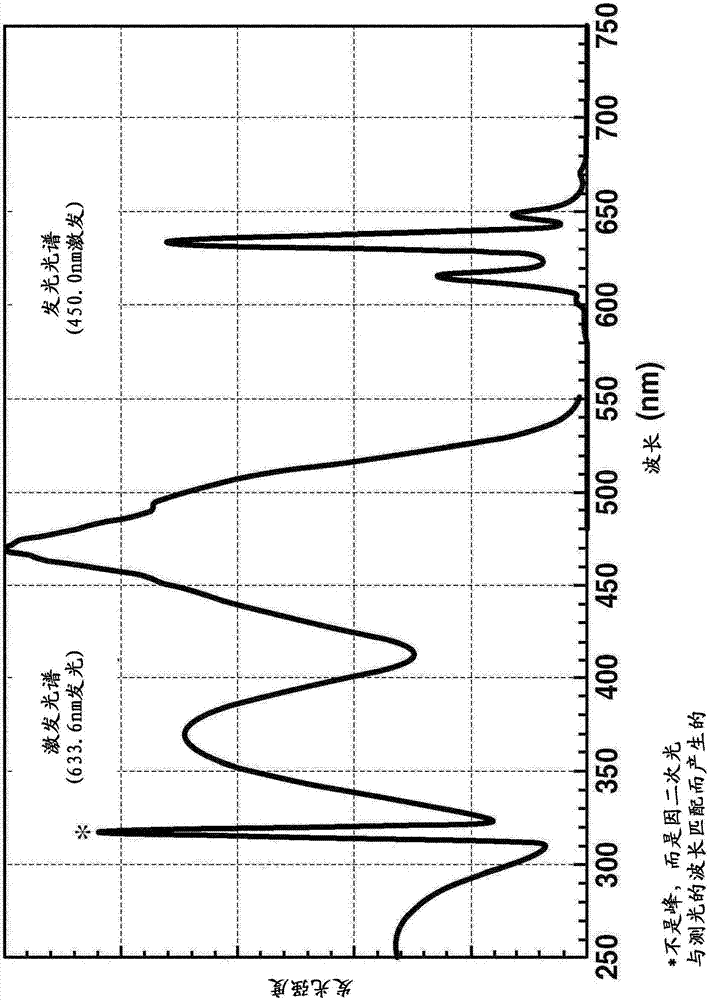

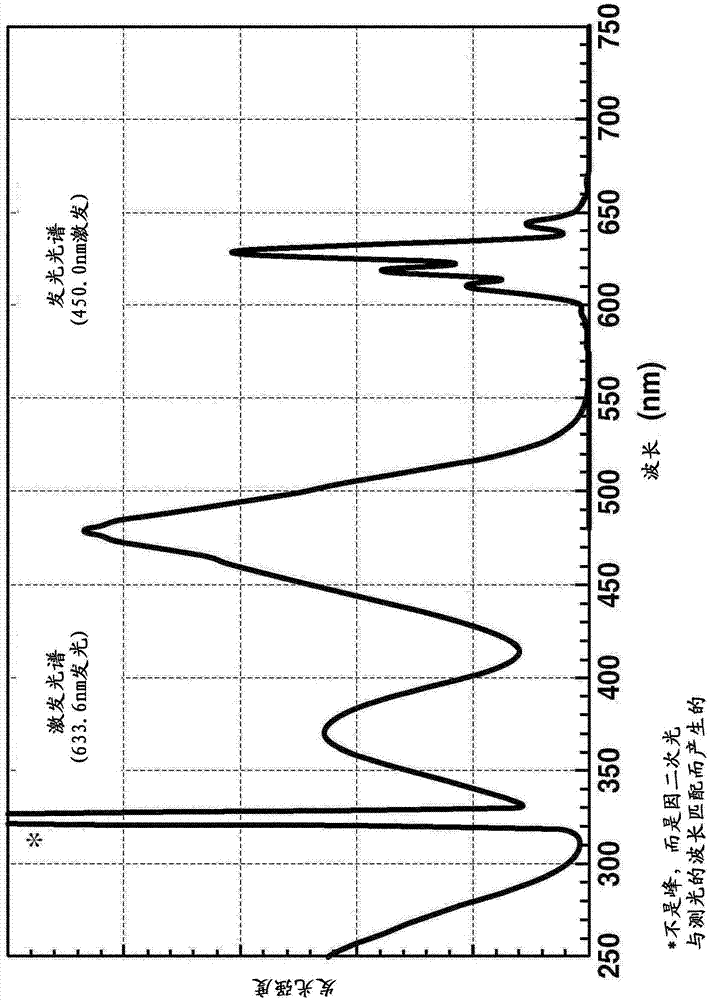

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminescence spectroscopy | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com