Production method of flexible self-support lithium-sulfur-battery positive-electrode material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor cycle life of lithium-sulfur batteries, poor conductivity of active materials, large changes in electrode volume, etc., to achieve good practicality Sexuality, low cost, and the effect of alleviating the loss of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

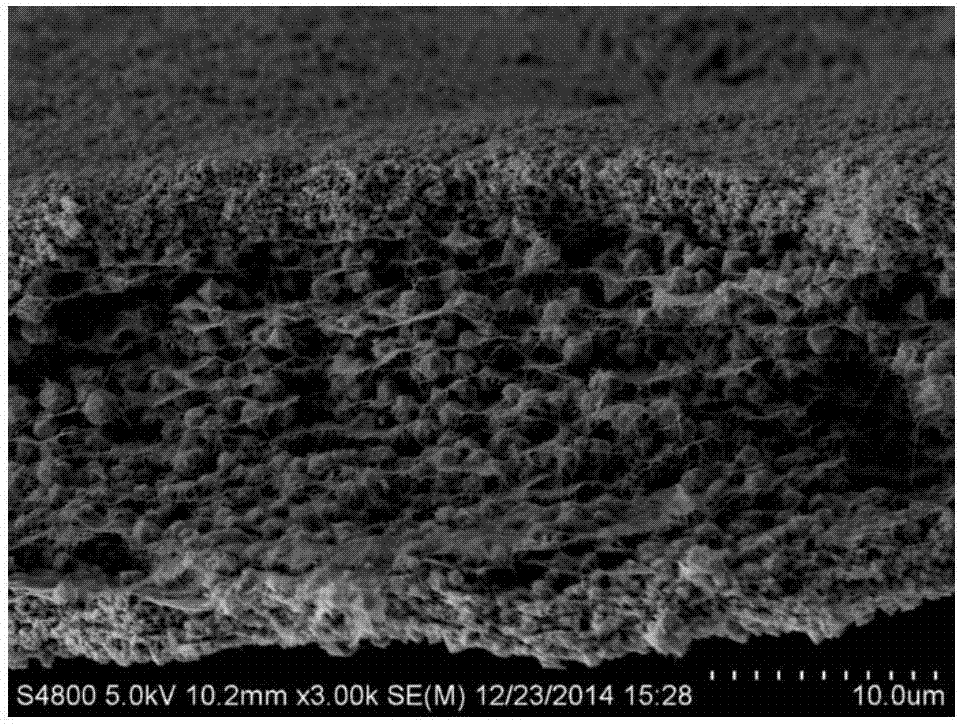

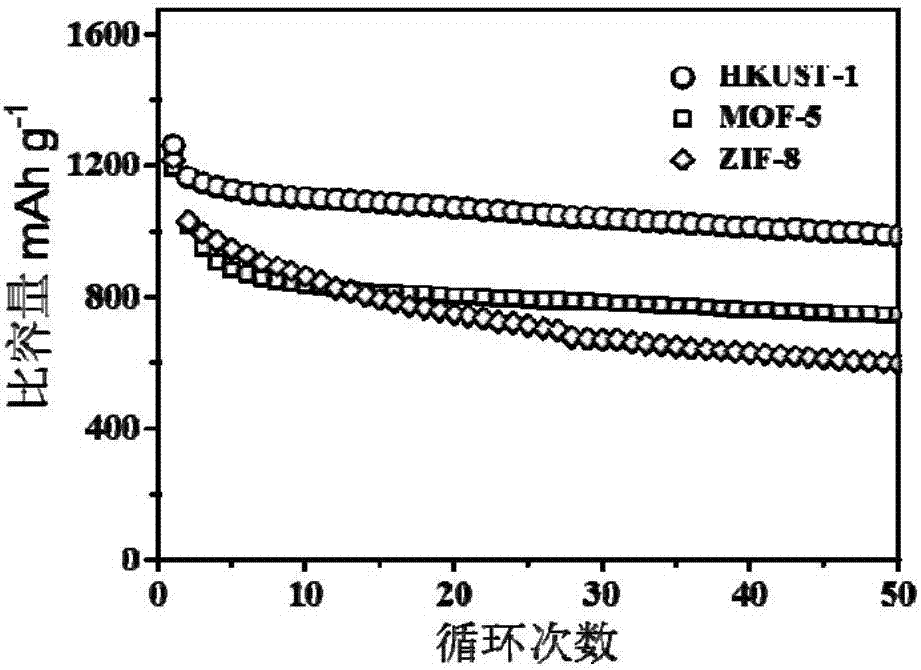

[0021] Copper nitrate and aminoethanol were uniformly mixed in the solution, and the copper hydroxide nanowire dispersion was obtained after soaking for 2 days. The single-walled carbon nanotubes were heated and oxidized in nitric acid at 80° C. for 1 day to obtain carbon nanotubes with negatively charged surfaces. The obtained 1mg copper hydroxide nanowires and 2mg carbon nanotubes are uniformly dispersed and mixed in water according to a certain mass ratio, then suction-filtered and dried on a porous substrate with a diameter of 2cm to obtain a self-supporting copper hydroxide / carbon nanotube composite membrane. The obtained copper hydroxide / CNT composite film was soaked in 20 mM trimesic acid water / ethanol mixed solution, and the solvent volume ratio was 1:1. A self-supporting HKUST-1 / CNT composite film was obtained after soaking at room temperature for 1 h. Dissolve sublimed sulfur in CS with stirring at room temperature 2 Get S / CS in 2 solution. The obtained solution ...

Embodiment 2

[0023] The zinc nitrate and aminoethanol were uniformly mixed in the solution, and the zinc hydroxide nanowire dispersion was obtained after soaking for 2 days. The single-walled carbon nanotubes were heated and oxidized in nitric acid at 80° C. for 1 day to obtain carbon nanotubes with negatively charged surfaces. The resulting 1 mg zinc hydroxide nanowires and 2 mg carbon nanotubes were uniformly dispersed and mixed in water, filtered on a porous substrate with a diameter of 2 cm, and dried to obtain a self-supporting zinc hydroxide / carbon nanotube composite membrane. The obtained zinc hydroxide / CNT composite film was soaked in 25 mM 2-methylimidazole water / ethanol mixed solution, and the solvent volume ratio was 4:1. A self-supporting ZIF-8 / CNT composite film was obtained after soaking at room temperature for 24 h. Dissolve sublimed sulfur in CS with stirring at room temperature 2 Get S / CS in 2 solution. The obtained solution was added to the obtained ZIF-8 / CNT composit...

Embodiment 3

[0025] The zinc nitrate and aminoethanol were uniformly mixed in the solution, and the zinc hydroxide nanowire dispersion was obtained after soaking for 2 days. The single-walled carbon nanotubes were heated and oxidized in nitric acid at 80° C. for 1 day to obtain carbon nanotubes with negatively charged surfaces. The resulting 1 mg zinc hydroxide nanowires and 2 mg carbon nanotubes were uniformly dispersed and mixed in water, filtered on a porous substrate with a diameter of 2 cm, and dried to obtain a self-supporting zinc hydroxide / carbon nanotube composite membrane. The obtained zinc hydroxide / CNT composite film was soaked in 20 mM terephthalic acid water / ethanol mixed solution, and the solvent volume ratio was 4:1. A self-supporting ZIF-5 / CNT composite film was obtained after soaking at 120°C for 12 h. Dissolve sublimed sulfur in CS with stirring at room temperature 2 Get S / CS in 2 solution. The obtained solution was added to the obtained ZIF-5 / CNT composite film acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com