A PD/W that improves the performance of hydrogen sensors 18 o 49 Preparation method of composite material

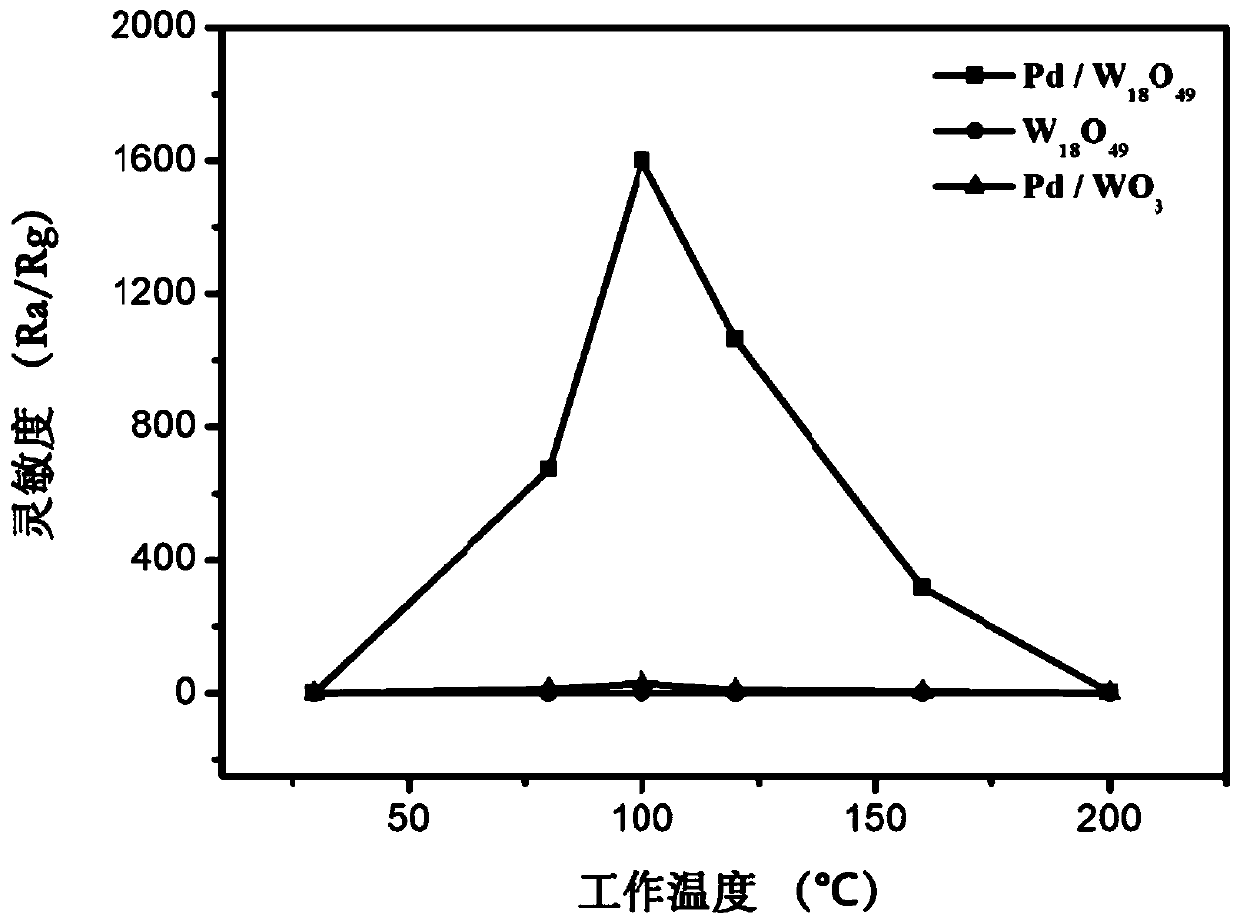

A technology of W18O49 and composite materials, applied in the field of preparation of Pd/W18O49 composite materials, can solve problems such as poor hydrogen response, and achieve the effects of low cost, abundant oxygen vacancies, and excellent gas sensing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 0.1g of tungsten hexachloride to 20mL of methanol solution under the condition of magnetic stirring, stir magnetically for 30min to obtain a uniform solution, and then put the uniform solution formed by them into a 25mL reaction kettle at 160°C Hydrothermal reaction 12h.

[0044] (2) The product obtained in step (1) is centrifuged, and the centrifuged product is first washed with ethanol for 3 times and then with deionized water for 3 times, and then put into a drying box for drying to obtain a sea urchin-like W 18 o 49 powder.

[0045] (3) Take 50 mg of dried sea urchin-shaped W 18 o 49 The powder was evenly dispersed in 100mL of deionized water, stirred magnetically for 30min to obtain a uniform solution, and then 3mL of 2.5mmol L -1 PdCl 2 The solution was stirred magnetically for 24h.

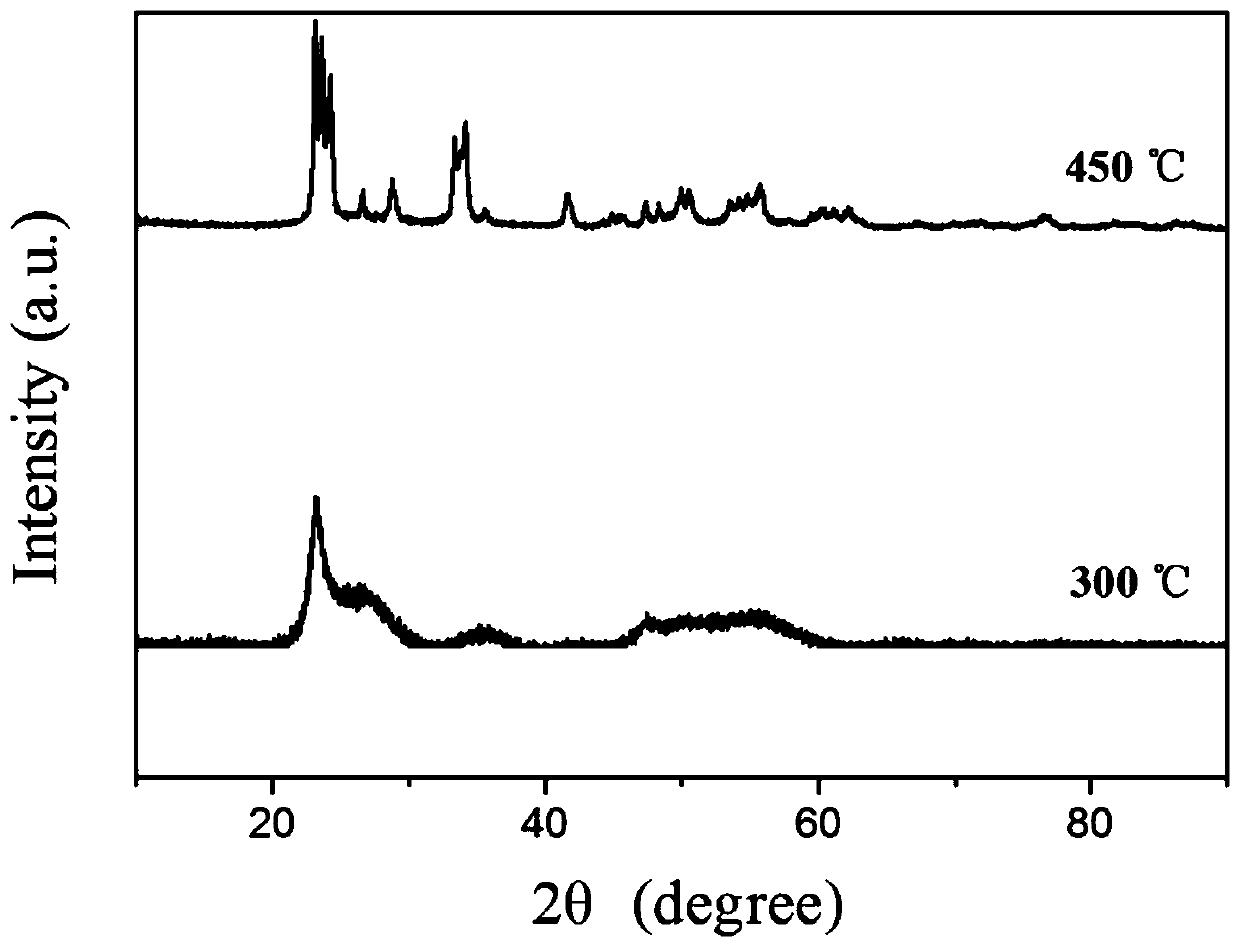

[0046] (4) The product obtained by ultrasonic stirring is washed, dried, and then annealed in air at 300°C for 2 hours to obtain the Pd / W 18 o 49 composite material. ...

Embodiment 2

[0056] (1) Add 0.08g of tungsten hexachloride to 20mL ethanol solution under the condition of magnetic stirring, and stir magnetically for 30min to obtain a uniform solution, and then put the uniform solution formed by them into a 25mL reaction kettle at 140°C Hydrothermal reaction 16h.

[0057] (2) The product obtained in step (1) is centrifuged, and the centrifuged product is first washed with ethanol for 3 times and then with deionized water for 3 times, and then put into a drying box for drying to obtain a sea urchin-like W 18 o 49 powder.

[0058] (3) Take 50 mg of dried sea urchin-shaped W 18 o 49 The powder was evenly dispersed in 100mL of deionized water, stirred magnetically for 30min to obtain a uniform solution, and then 3mL of 2.5mmol L -1 PdCl 2 The solution was stirred magnetically for 24h.

[0059] (4) The product obtained by ultrasonic stirring is washed, dried, and then annealed in air at 300°C for 2 hours to obtain the Pd / W 18 o 49 composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com