Oil-gas blocking and sealing material

A plugging material and oil and gas technology, applied in the field of oil drilling, can solve problems such as the inability to block and block oil and gas, and the lack of sensitive properties of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1.1 Sample preparation

[0065] Hexadecyl methacrylate, undecylenic acid, and styrene were dissolved in xylene to prepare a monomer solution with a mass concentration of 40 wt%, wherein the mass fraction of cetyl methacrylate was 30.0%, and undecyl The mass fraction of alkenoic acid is 7.0%, the mass fraction of styrene is 3.0%, and the rest is xylene. Ethylene-propylene rubber particles with a median diameter of 5 mm were swelled in a monomer solution for 6 hours in a diffusion-controlled manner to obtain a prepolymer. After adding 50wt% white carbon black to the obtained prepolymer, high-energy electron irradiation is carried out at room temperature to initiate the monomer to carry out graft polymerization reaction inside and on the surface of the rubber particle, and the irradiation intensity is 120kGy; After drying under vacuum for 12 hours at °C, it was pulverized to obtain an oil-gas blocking and plugging material with a particle size of 30-60 mesh.

[0066] 1.2...

Embodiment 2

[0075] Dissolve octadecyl acrylate, hexenoic acid, and styrene in dichloromethane to prepare a monomer solution with a mass concentration of 52.5 wt%, wherein the mass fraction of octadecyl acrylate is 45.30%, and the mass fraction of hexenoic acid The fraction is 4.35%, the mass fraction of styrene is 2.85%, and the rest is dichloromethane. Diffusion-controlled swelling of isoprene rubber particles with a median diameter of 8 mm in the monomer solution for 8 hours to obtain a prepolymer. After adding 30wt% magnesium stearate to the resulting prepolymer, Co 60 Irradiation is used to initiate the graft polymerization reaction of monomers in the interior and surface of rubber particles, and the irradiation intensity is 180kGy; after that, the product is vacuum-dried at 80°C for 8 hours, and then pulverized to obtain an oil-gas blocking seal with a particle size of 20-80 meshes. blocking material.

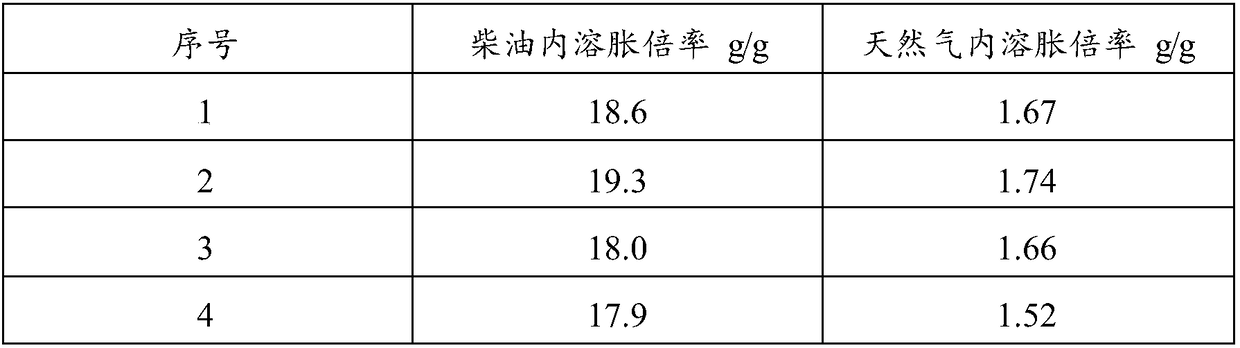

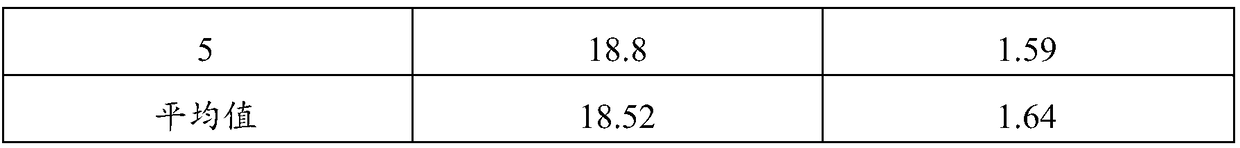

[0076] According to the test method of Example 1, the oil and gas sensitivity t...

Embodiment 3

[0080]Dissolve lauryl methacrylate, undecylenic acid, and styrene in benzene to prepare a monomer solution with a mass concentration of 20 wt%, wherein the mass fraction of lauryl methacrylate is 12.5%, undecylenic acid The mass fraction of acid is 4.70%, the mass fraction of styrene is 2.80%, and the rest is benzene. The butyl rubber particles with a median diameter of 2 mm were subjected to diffusion-controlled swelling in the monomer solution for 36 hours to obtain a prepolymer. After adding 80wt% silicon dioxide to the obtained prepolymer, add 0.1wt% initiator 2-hydroxyl-methylphenylpropane-1-ketone that accounts for the total amount of the system, and initiate the monomer to carry out in the inside and surface of the rubber particle The graft polymerization reaction was irradiated with an ultraviolet light source with a wavelength of 264nm, and the reaction lasted for 12 hours; after that, the product was vacuum-dried at 50°C for 12 hours, and then pulverized to obtain an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com