Solid lubricant, lubricating coating agent for metal material, surface-treated metal material, and method for forming lubricating coating for metal material

A technology of solid lubricants and metal materials, applied in the direction of lubricating compositions, base materials, additives, etc., can solve problems such as poor economy, high price of molybdenum disulfide, and pollution of the operating environment, to prevent ablation or seizure, Excellent environmental protection and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

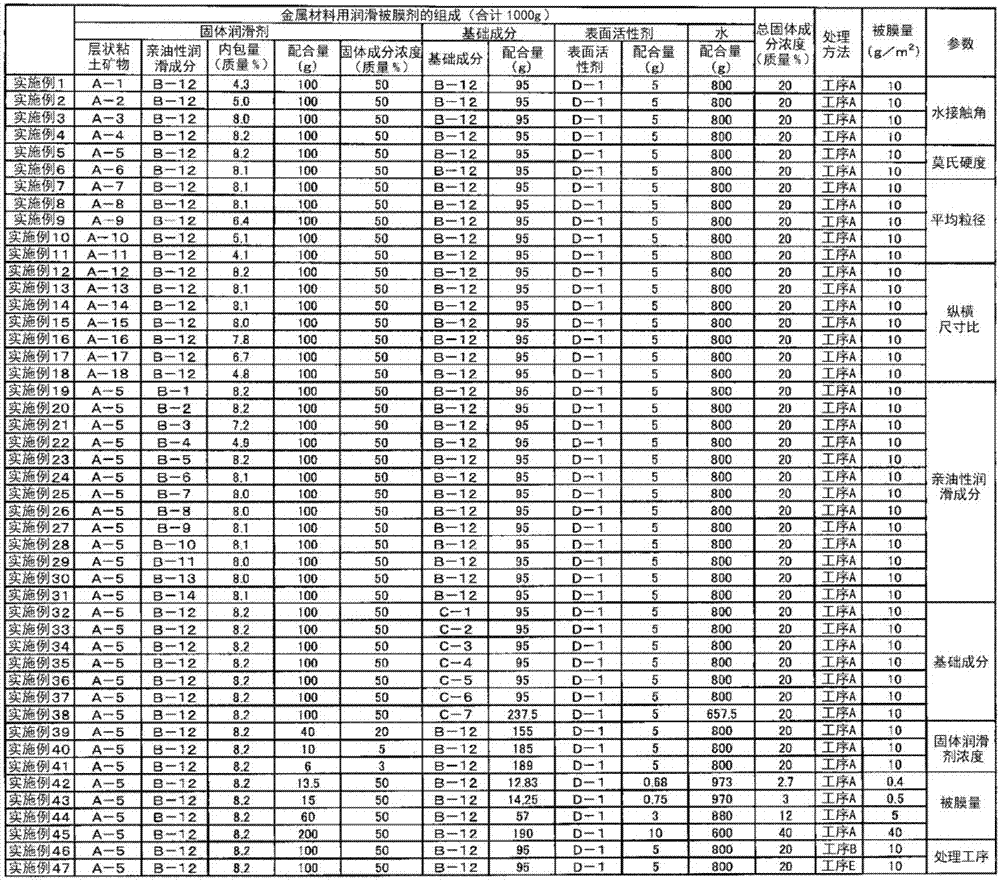

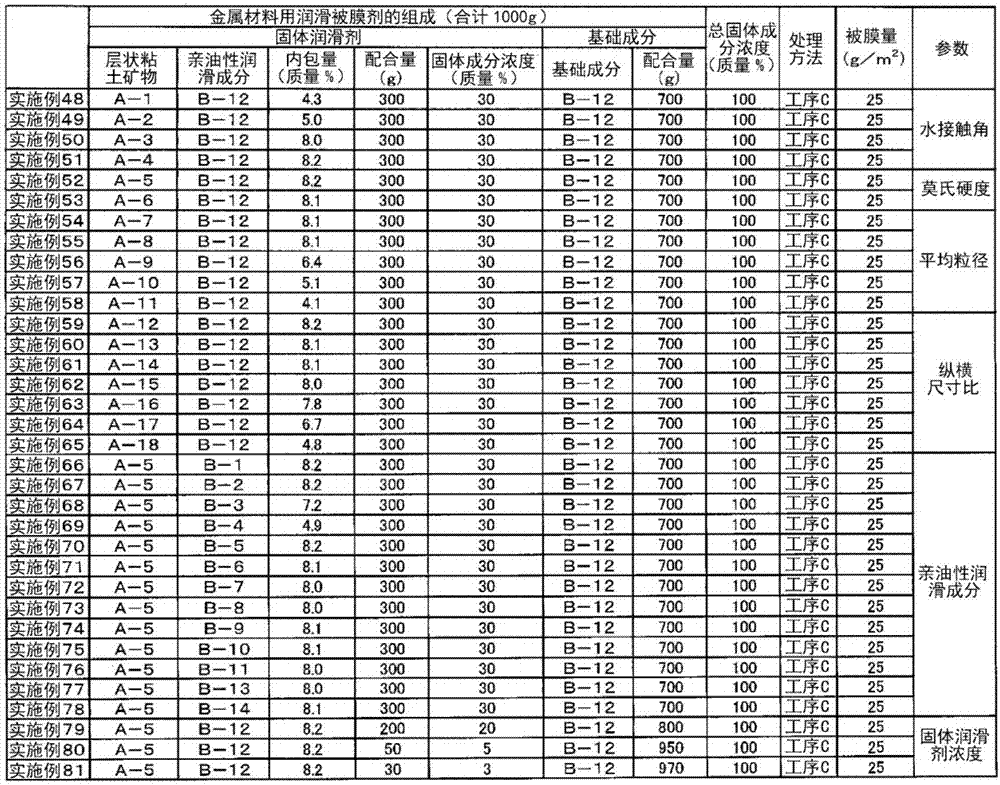

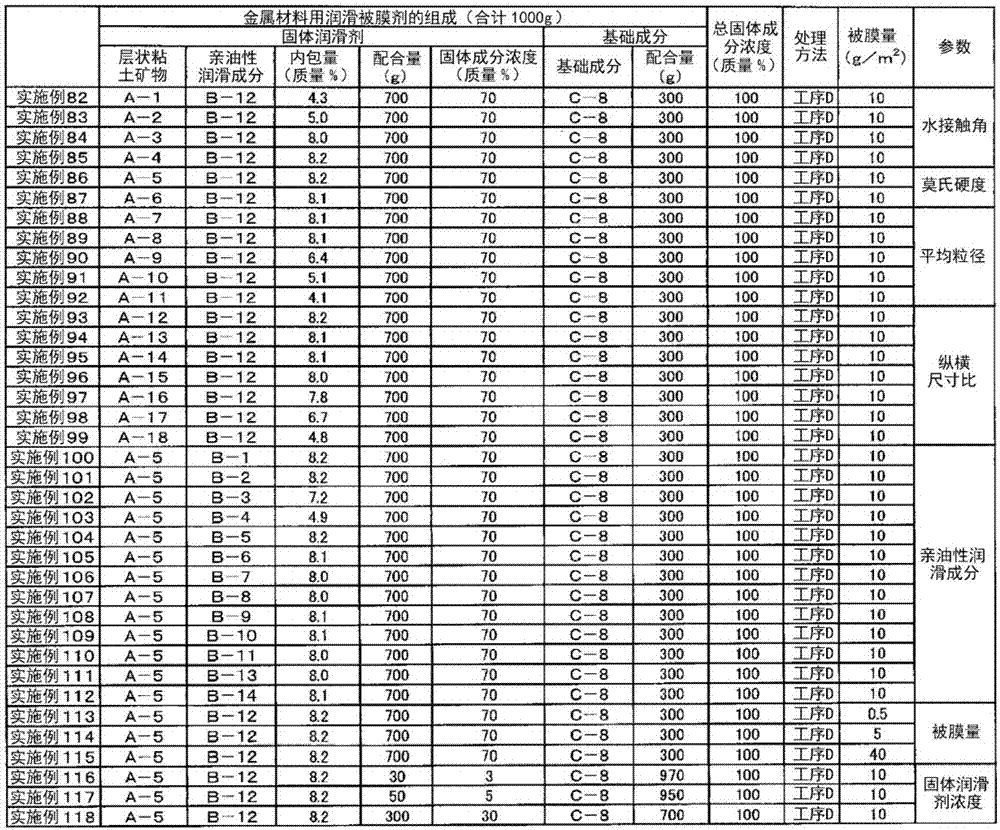

[0090] The effect of this invention was verified using an Example and a comparative example. When producing the lubricating coating agents for metal materials used in Examples and Comparative Examples, details of each component are shown below.

[0091] [Description of raw materials used in the manufacture of lubricating coatings]

[0092]The details of the layered clay mineral (the layered clay mineral before enclosing a lipophilic lubricating component) used in the test are shown below. The average particle size of layered clay minerals is measured under the following conditions by volume-based laser diffraction after the layered clay minerals are redispersed in water for 3 minutes by ultrasonic waves to form primary particles .

[0093] Measuring machine name: Horiba Manufacturing Co., Ltd. LA-920

[0094] Number of data imports: 10 times

[0095] Number of operations: 30 times

[0096] Ultrasonic Intensity: 7

[0097] Ultrasonic time: 3 minutes

[0098] Dispersion m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com