Method for preparing sponge supported iron oxide nanoparticle composite material synthesized in situ

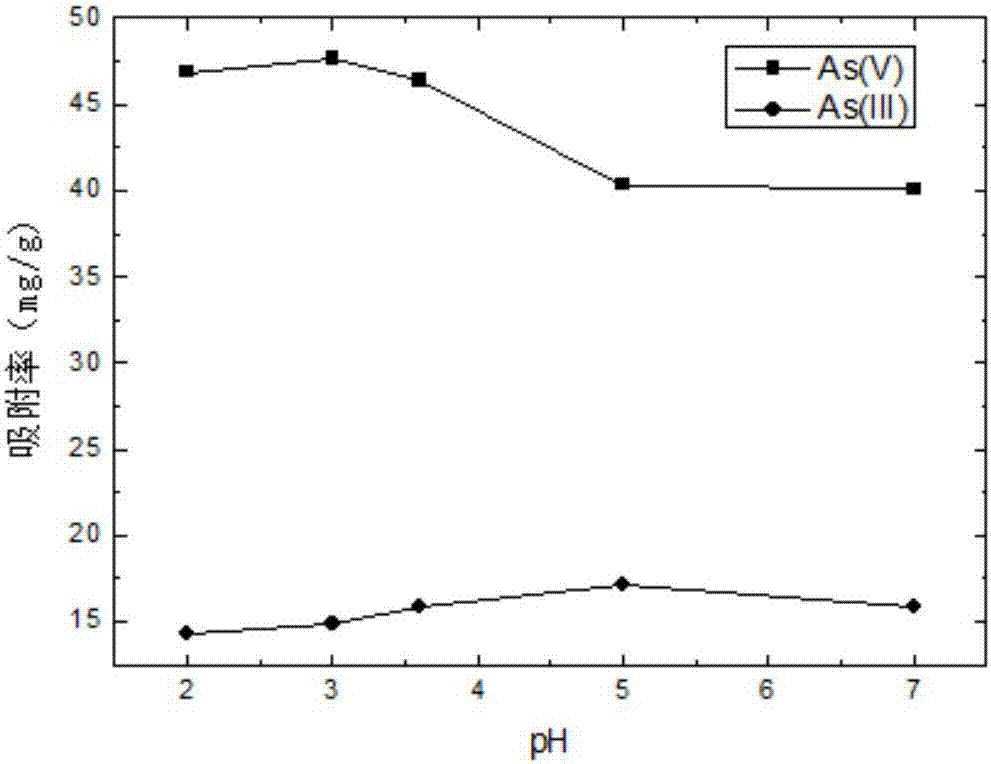

A technology of iron oxide nano and composite materials, which is applied in the field of material chemistry, can solve the problems of not being able to overcome the Brownian motion of particles and the difficulty of magnetic separation, and achieve the effects of easy separation, recycling and reuse, low cost, and small diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

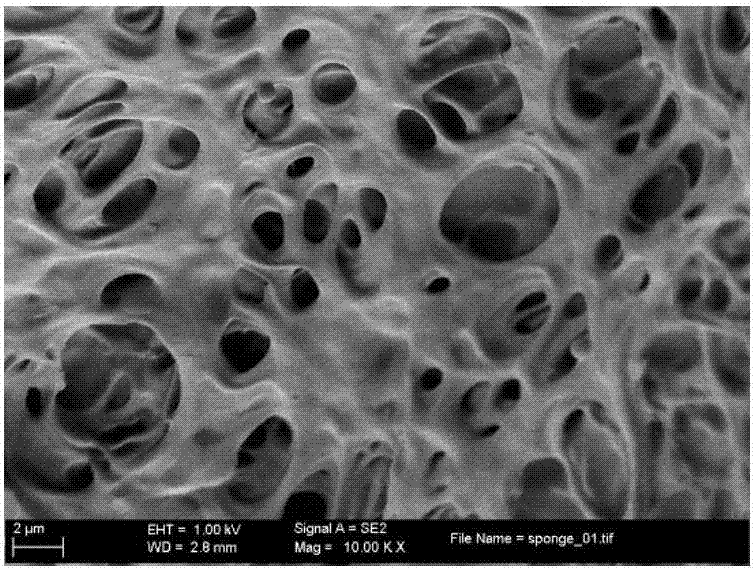

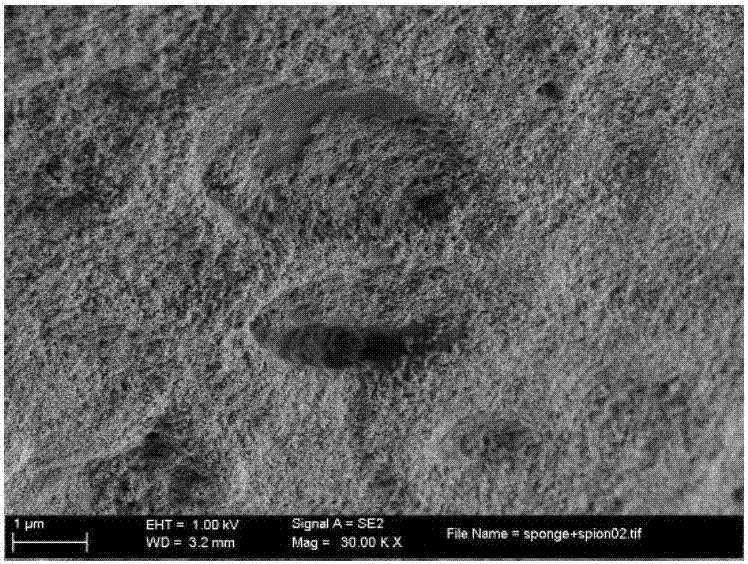

[0053] Use a crusher to crush the blocky sponge into powder, wash it once with 0.2M hydrochloric acid solution, wash it several times with deionized water, put it in an oven at 40°C, and dry it for 24 hours for later use; prepare FeCl 3 .6H 2 O solution: 6.48g FeCl 3 .6H 2 Dissolve O in 0.2M hydrochloric acid solution and stir until it is completely dissolved, and pass nitrogen gas for 30-60 minutes; weigh 4g of washed and dried sponge powder, add 500mL 0.7M ammonia water, pass nitrogen gas for 45 minutes, and then heat the ammonia water Mix the system with sponge powder to 70°C, and keep nitrogen flowing; when the mixed system of ammonia water and sponge is heated to 70°C, add the prepared FeCl 3 .6H 2 O solution was stirred and reacted for 30min, then 2.44g FeCl was added 2 .4H 2 O powder, stirred rapidly and reacted at 70°C for 45min; after that, cooled to room temperature, separated the solid-liquid of the in-situ synthesized sponge-loaded iron oxide nanoparticle comp...

Embodiment 2

[0057] Use a crusher to crush the blocky sponge into powder, wash it once with 1.0M hydrochloric acid solution, wash it several times with deionized water, put it in an oven at 60°C, and dry it for 12 hours; prepare FeCl 3 .6H2O solution: 4.92g FeCl 3 .6H 2 O and 1.86 FeCl 2 .4H 2 O was dissolved in 0.2M hydrochloric acid solution and stirred until it was completely dissolved, and nitrogen gas was passed in for 60 minutes; 3 g of the cleaned and dried sponge powder was weighed, added to ammonia water, and nitrogen gas was passed in for 60 minutes; then, the mixed system of ammonia water and sponge was heated to 65 ℃, keep nitrogen flowing; when the mixed system of ammonia water and sponge is heated to 65 ℃, add the prepared FeCl 3 .6H 2 O and FeCl 2 .4H 2 O mixed solution was stirred and reacted for 45 min; after that, cooled to room temperature, the in situ synthesized sponge-loaded iron oxide nanoparticle composite material was separated from solid and liquid, and the ...

Embodiment 3

[0061] Use a crusher to crush the blocky sponge into powder, wash it once with 1.0M hydrochloric acid solution, wash it several times with deionized water, put it in an oven at 60°C, and dry it for 12 hours; prepare FeCl 3 .6H 2 O, FeCl 2 .4H 2 O and sponge solution: 3.24g FeCl 3 .6H 2 O and 1.24 g FeCl 2 .4H 2 O was dissolved in 0.2M hydrochloric acid solution and stirred until completely dissolved; Weighed 4g of prepared, washed and dried sponge powder, soaked in it, and passed nitrogen gas for 60 minutes; heated ammonia water to 70°C, continued to maintain nitrogen gas flow, and added the Prepared FeCl 3 .6H 2 O, FeCl 2 .4H 2 O and the sponge mixed solution were stirred and reacted for 30 minutes; after that, cooled to room temperature, the in-situ synthesized sponge-loaded iron oxide nanoparticle composite material was separated from solid and liquid, and the excess ammonia solution on the surface was cleaned with deionized water, and then cleaned once with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com