A staged combustion boiler system and method for oxygen-lean combustion catalytic oxidation of molten slag

A catalytic oxidation and lean-oxygen combustion technology, applied in the field of boilers, can solve problems such as the impact of ammonia injection, poor denitration efficiency, waste disposal problems, etc., and achieve the effects of reducing environmental pollution, reducing air pollution, high efficiency and low NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

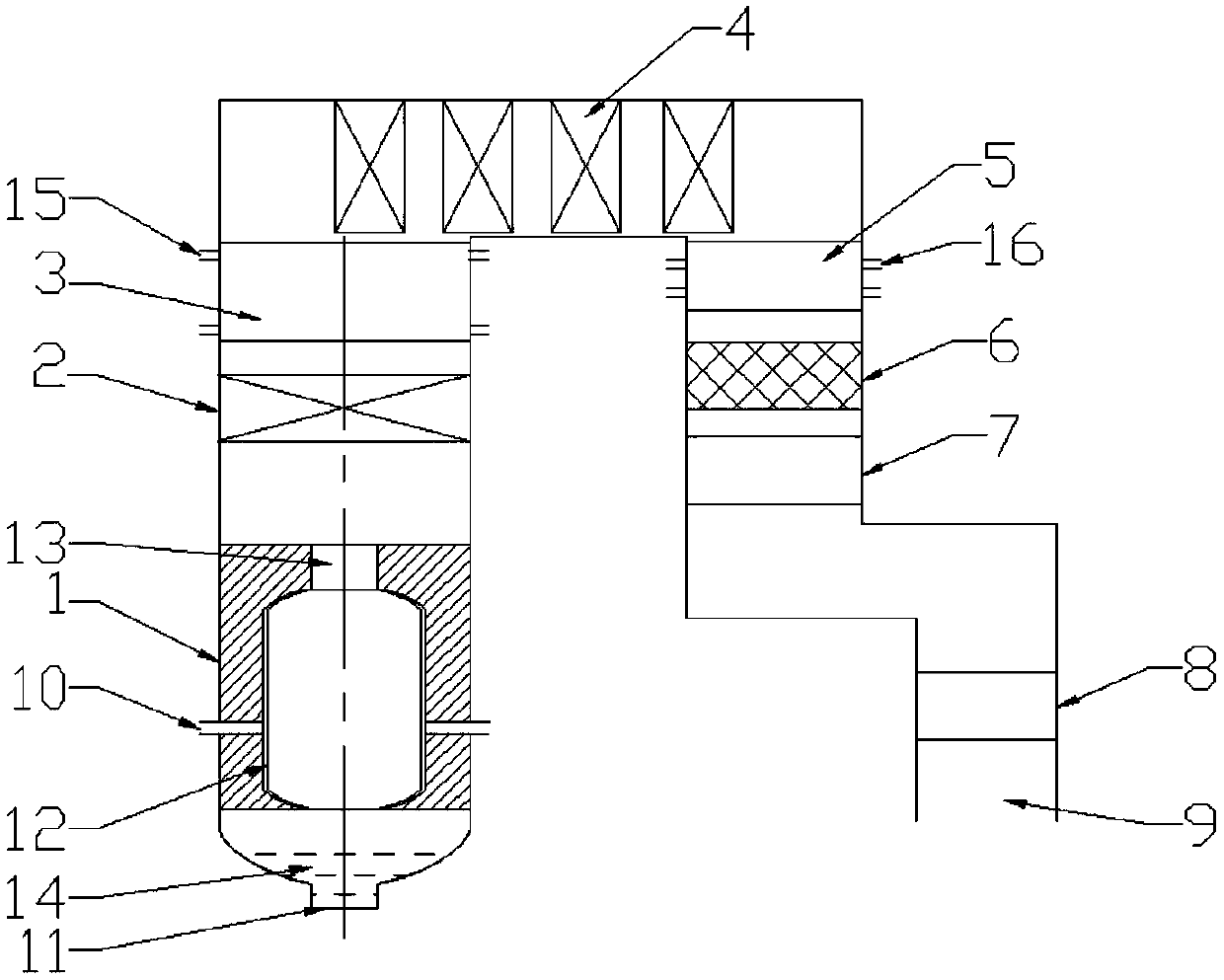

[0035] refer to figure 1 As shown, a staged combustion boiler system for oxygen-lean combustion catalytic oxidation of slag according to the present invention includes an oxygen-lean combustion chamber 1, a CO catalytic oxidation device 6 and other equipment of the boiler body.

[0036] The oxygen-lean combustion chamber 1 is located at the furnace of the boiler system, and other equipment of the boiler body includes a sparsely arranged convective heating surface 2, a secondary combustion chamber 3, a convective heating surface 4, an air supply chamber 5, an economizer 7, and an air preheater 8 And the smoke outlet 9, the CO catalytic oxidation device 6 is set between the economizer 7 and the supplementary air chamber 5.

[0037] The upper part of the oxygen-poor combustion chamber 1 is connected with the first vertical flue; the convection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com