Titanium silicalite molecular sieves as well as synthesis method and application thereof

A technology of titanium-silicon molecular sieve and synthesis method, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of poor stability and low catalyst activity of titanium-silicon materials, and achieve selectivity improvement and preparation The process is simple and conducive to the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

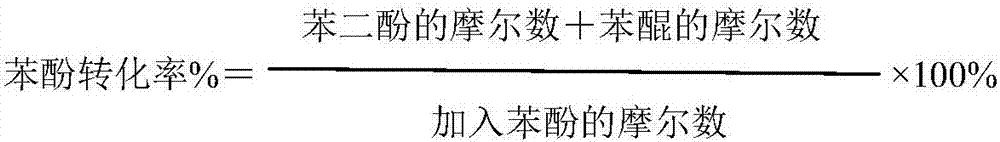

Examples

preparation example Construction

[0015] As previously mentioned, the present invention provides a kind of synthetic method of titanium silicon molecular sieve, this method comprises:

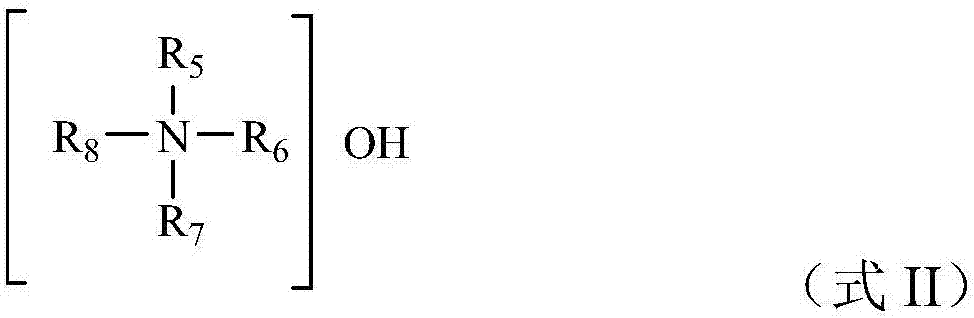

[0016] (1) mixing and contacting a precious metal source, an ammonia source, and optionally water to obtain a first mixture;

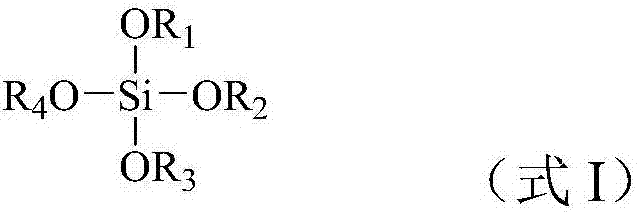

[0017] (2) In the presence of a templating agent, mixing the titanium source, the first mixture, and optionally water to obtain a second mixture;

[0018] (3) mixing the second mixture, the organic silicon source, and optionally water to obtain a third mixture;

[0019] (4) subjecting the third mixture to hydrothermal crystallization, and recovering titanium-silicon molecular sieves;

[0020] Wherein, at least one of step (1), step (2) and step (3) is carried out in the presence of vanadium source.

[0021] According to the present invention, preferably step (1) is carried out in the presence of a vanadium source, thereby improving the catalytic activity of the titanium-silicon molecular sieve.

[00...

Embodiment approach

[0028] According to a preferred embodiment of the present invention, the preferred stage (1) and stage (3) meet one or both of the following conditions:

[0029] Condition 1: the temperature of stage (1) is lower than the temperature of stage (3), preferably, the temperature of stage (1) is 10-50°C lower than the temperature of stage (3), preferably 20-40°C lower;

[0030] Condition 2: the time of stage (1) is less than the time of stage (3), preferably, the time of stage (1) is 5-24 hours shorter than the time of stage (3), preferably 6-12 hours shorter.

[0031] According to a preferred embodiment of the present invention, the temperature in stage (2) is lowered to not higher than 50°C, preferably 30-50°C, and the residence time is at least 1 hour, preferably 1-5h.

[0032] According to the method of the present invention, the heating rate and cooling rate for adjusting the temperature to the temperature of each stage can be selected according to the type of the reactor used...

Embodiment 1

[0082] (1) The precious metal source palladium chloride, vanadium source vanadium nitrate and ammonia (concentration is 20% by weight) are mixed and contacted to obtain a mixture; precious metal source: ammonia source (weight ratio)=2:20, solute content is 1% by weight, mixed Contact conditions include: 30°C, normal pressure, 4h;

[0083] (2) The mixture is then mixed with tetrabutyl titanate and tetrapropyl ammonium hydroxide;

[0084] (3) Then add tetraethyl orthosilicate, carry out hydrothermal crystallization after mixing, the hydrolysis rate of organosilicon source is 15%; Silicon source: titanium source: precious metal source: vanadium source: templating agent: the molar ratio of water=100 :2:1:1:15:1000;

[0085] Hydrothermal crystallization: go through the first stage at 140°C for 6 hours in a sealed reactor, then cool the mixture down to 30°C and experience the second stage for 2 hours, then continue to go through the third stage at a temperature of 170°C in a sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com