Method for directly preparing erythromycin oxime by utilizing erythromycin fermentation liquid

A technology for erythromycin oxime and erythromycin, which is applied in the field of drug synthesis, can solve the problems of affecting the quality and yield of erythromycin oxime products, unstable chemical properties of erythromycin A, adding more organic solvents, etc. By-product formation, high product yield, and the effect of reducing the pressure of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

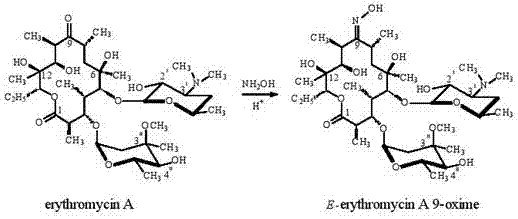

Image

Examples

Embodiment 1

[0030] Take 50L of erythromycin fermentation broth, under the conditions of pH 8.0 and pressure 0.2MPa, use an organic plate membrane with a pore size of 5-50nm to filter, during the process of peristaltic pump flow plus pure water dialysis; the obtained filtrate 110L is subjected to roll-type nanofiltration Membrane concentration, the membrane with a molecular weight cut-off of 700 or more, the pH of the filtrate during the concentration process is controlled at 6.5-7.5, the pressure is controlled at 4.0MPa, and the concentration of the obtained concentrated solution is 2.23g / 100ml; the concentrated solution is added with 50L butyl acetate and 10% hydrogen Sodium oxide solution for extraction, the pH of the extraction process is controlled at 10.0 to 10.5, stand still and separate phases, separate to obtain the upper layer of butyl acetate solution, add 1% activated carbon to filter, distill and concentrate the butyl acetate solution under reduced pressure, and cool down to bel...

Embodiment 2

[0034] Take 50L of erythromycin fermentation broth, under the conditions of pH 8.2 and pressure 0.22MPa, use an organic plate membrane with a pore size of 5-50nm to filter. During the process, a peristaltic pump flow is added to pure water for dialysis, and 110L of the obtained filtrate is concentrated by nanofiltration. For membranes with a molecular weight cut-off of 700 or more, the pH of the filtrate during the concentration process is controlled at 6.5 to 7.5, the pressure is controlled at 3.9MPa, and the concentration of the resulting concentrated solution is 2.12g / 100ml; Extraction, the pH of the extraction process is controlled at 9.0 to 9.5, stand still and separate the phases, separate to obtain the lower layer of dichloromethane solution, add 1.5% diatomaceous earth to filter, distill and concentrate the dichloromethane solution under reduced pressure, cool to below -15°C to crystallize, Insulated and stirred for 3 hours, centrifuged to obtain erythromycin crude base...

Embodiment 3

[0038] Take 50L of erythromycin fermentation broth, under the conditions of pH 7.8 and pressure 0.16MPa, filter it with an organic plate membrane with a pore size of 5-50nm. The nanofiltration membrane is a membrane with a molecular weight cut-off of more than 700. The pH of the filtrate during the concentration process is controlled at 6.5 to 7.5, and the pressure is controlled at 3.8MPa. The concentration of the concentrated solution is 2.22g / 100ml; Add 15% sodium carbonate solution for extraction, the pH of the extraction process is controlled at 9.5-10.0, stand still and separate the phases, separate to obtain the upper layer of methyl tert-butyl ether solution, add 0.5% polymer filter aid to filter, vacuum distillation and concentration The methyl tert-butyl ether solution was cooled to below -10°C for crystallization, kept stirring for 2 hours, and centrifuged to obtain crude erythromycin base. The obtained erythromycin crude base after drying has a content of 91.6% eryt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com