Nano TiO2 in-situ hybridization antibacterial waterproof coating treatment agent and preparation method thereof

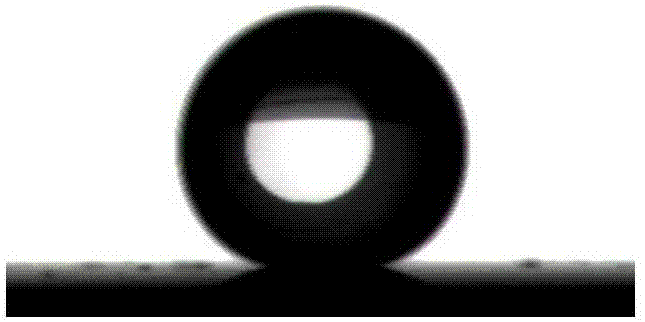

A waterproof coating and coating treatment technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of small size, easy deposition, easy volatilization, etc., to achieve good hydrophobic effect, Damage reduction, non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of nano TiO 2 The preparation method of in-situ hybridization antibacterial waterproof coating treatment agent is characterized in that comprising the following steps:

[0033] Step (1) Prepare titanate alcohol solution: take 15 parts of butyl titanate and dissolve in 100 parts of anhydrous butanol solvent, stir evenly to obtain titanate alcohol solution;

[0034] Step (2) Prepare the acid catalyst solution: take 5 parts of glacial acetic acid and 20 parts of deionized water, stir evenly, add a small amount of hydrochloric acid dropwise, and adjust the pH value of the solution to 2-3;

[0035] Step (3) Prepare the alcohol solution of isooctyltrimethoxysilane: take 50 parts of silane coupling agent and dissolve in 40 parts of anhydrous butanol solvent, stir evenly to obtain the alcohol solution of silane coupling agent;

[0036] Step (4) Nano TiO 2 Sol preparation: under nitrogen protection and stirring, slowly add the acid catalyst solution prepared in step (2)...

Embodiment 2

[0039] A kind of nano TiO 2 The preparation method of in-situ hybridization antibacterial waterproof coating treatment agent is characterized in that comprising the following steps:

[0040] Step (1) Prepare titanate alcohol solution: take 15 parts of isopropyl titanate and dissolve in 100 parts of anhydrous butanol solvent, stir evenly to obtain titanate alcohol solution;

[0041] Step (2) Prepare the acid catalyst solution: take 5 parts of glacial acetic acid and 20 parts of deionized water, stir evenly, add a small amount of hydrochloric acid dropwise, and adjust the pH value of the solution to 2-3;

[0042] Step (3) Prepare the alcohol solution of isooctyltrimethoxysilane: take 50 parts of silane coupling agent and dissolve in 40 parts of anhydrous butanol solvent, stir evenly to obtain the alcohol solution of silane coupling agent;

[0043] Step (4) Nano TiO 2 Sol preparation: under nitrogen protection and stirring, slowly add the acid catalyst solution prepared in step...

Embodiment 3

[0046] A kind of nano TiO 2 The preparation method of in-situ hybridization antibacterial waterproof coating treatment agent is characterized in that comprising the following steps:

[0047] Step (1) Prepare titanate alcohol solution: take 15 parts of butyl titanate and dissolve in 100 parts of anhydrous butanol solvent, stir evenly to obtain titanate alcohol solution;

[0048] Step (2) Prepare the acid catalyst solution: take 5 parts of glacial acetic acid and 20 parts of deionized water, stir evenly, add a small amount of hydrochloric acid dropwise, and adjust the pH value of the solution to 2-3;

[0049] Step (3) Prepare the alcohol solution of isobutyltrimethoxysilane: take 50 parts of silane coupling agent and dissolve in 40 parts of anhydrous butanol solvent, stir evenly to obtain the alcohol solution of silane coupling agent;

[0050] Step (4) Nano TiO 2 Sol preparation: under nitrogen protection and stirring, slowly add the acid catalyst solution prepared in step (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com