MEMS optical device, light absorption nano structure and preparation method thereof

A nanostructure and light absorption technology, applied in optical components, optics, nanotechnology, etc., can solve the problems of relying on control process accuracy, application field limitations, and high preparation costs, achieving simple and convenient process, low processing cost, and improved absorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the disclosed light-absorbing nanostructure comprises the following steps:

[0052] provide the basis;

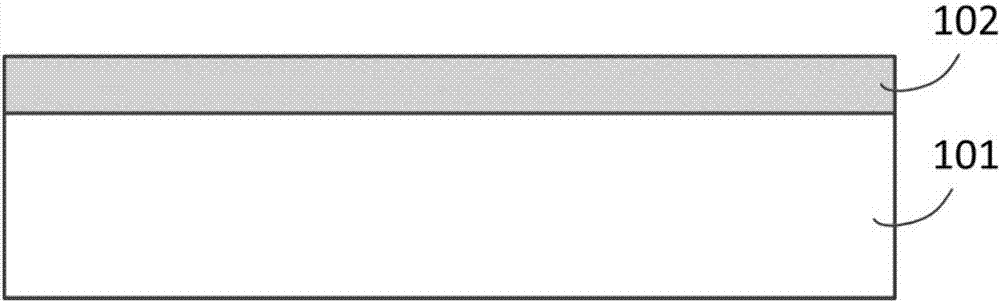

[0053] forming a polymer layer on the substrate;

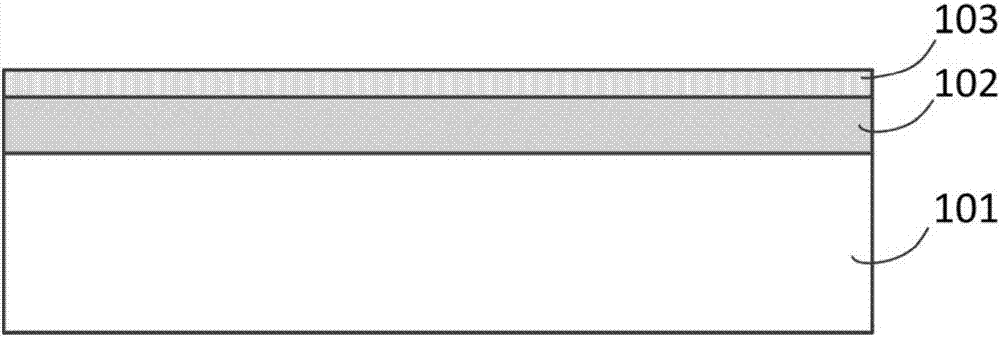

[0054] forming a nanoforest structure using the polymer layer; and

[0055] The nano-forest structure is covered with metal nanoparticles and / or metal nano-films.

[0056] Further, the preparation method of the light-absorbing nanostructure may further include: sequentially forming a specular metal reflection layer and a planar dielectric layer between the substrate and the polymer layer, and further, between the planar dielectric layer and the polymer layer A silicon thin film layer may be formed.

[0057] Furthermore, the preparation method of the light-absorbing nanostructure may further include: forming a titanium nitride adhesion layer between the specular metal reflection layer and the substrate.

[0058] Specifically, the different nano-forest structures are formed by using plasma...

Embodiment 1

[0068] In this embodiment, single crystal silicon is used as the substrate, and an aluminum mirror metal reflective layer and a silicon oxide planar dielectric layer are sequentially formed on the substrate by a sputtering process and a plasma-enhanced chemical vapor deposition (PEVCD) process, thus forming a multilayer optical Reflective and optically coupled substrates. The nanofiber forest structure is formed by sequentially bombarding the polyimide positive photoresist layer with oxygen and argon plasma, and the metal nanostructure is silver nanoparticles or silver nanofilms formed by sputtering metallic silver on the nanofiber forest structure . The method is realized based on conventional micro-nano processing technology, the preparation process is simple and convenient, and large-scale commercial production can be realized.

[0069] refer to Figures 1 to 7 , the preparation method of the light-absorbing nanostructure according to Embodiment 1 of the present disclosur...

Embodiment 2

[0090] In this embodiment, a silicon film layer is formed on a multi-layer light reflection and light coupling substrate, and a nanofiber forest structure is further formed on the silicon film layer, and a nanocone is formed by anisotropic etching using the nanofiber forest structure as a mask The nanofiber has a double-layer forest structure, and through subsequent metal sputtering, a metal nanofilm is formed on the upper nanofiber, and metal nanoparticles are formed on the lower nanocone, finally forming a double-layer light-absorbing nanostructure.

[0091] Please refer to Figures 8 to 12 , the preparation method of the light-absorbing nanostructure in Example 2 of the present disclosure specifically includes the following steps:

[0092] S21, providing a multilayer light reflection and light coupling substrate.

[0093] The multilayer light reflecting and light coupling substrate comprises Figure 8 Shown are a second substrate 201 , a specular metal reflection layer 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com