Nanometer cross-linked sodium hyaluronate gel, preparation method and applications thereof

A technology of cross-linking hyaluronic acid and hyaluronic acid, which is applied in the field of moisturizing masks and essences, can solve problems such as inability to enter the skin, and achieve moisturizing effect to repair skin, better moisturizing and wrinkle repair effect, and long acting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

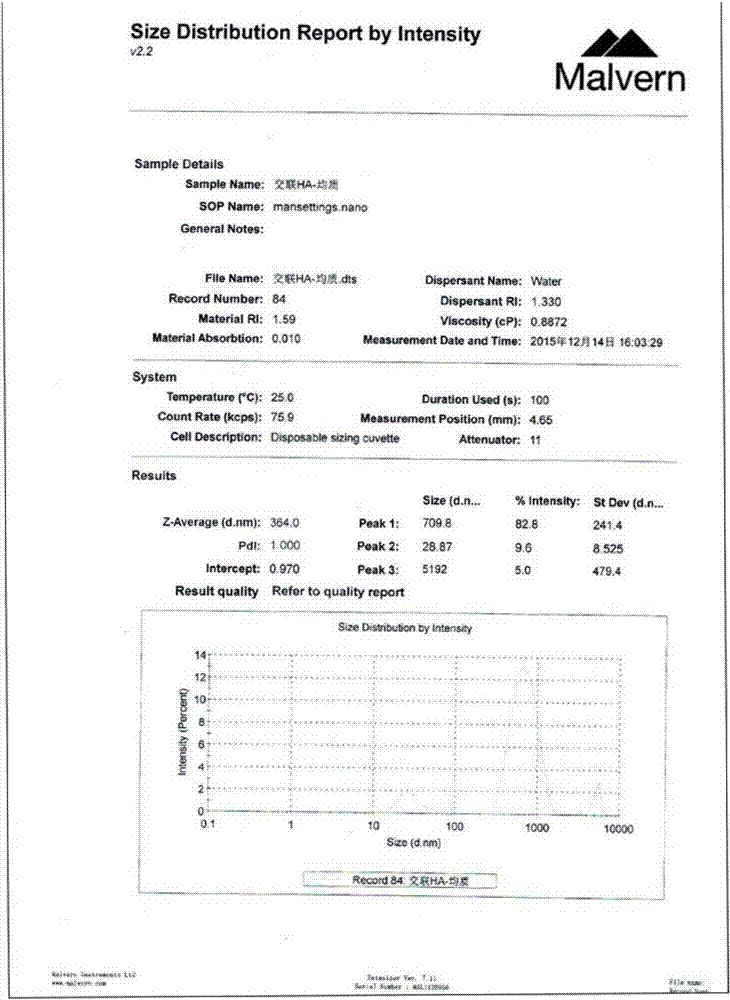

[0032] The average particle diameter of the nano-crosslinked hyaluronic acid gel in this embodiment is 364nm.

[0033] The preparation method of the above-mentioned nano-crosslinked hyaluronic acid gel comprises the following steps:

[0034] ① Add 25% to 45% (40wt% in this example) of 15 to 25 times its weight (20 times in this example) of cross-linked sodium hyaluronate dry powder at a temperature lower than 40°C Aqueous acetone solution, fully stirred to obtain a suspension.

[0035] The cross-linked sodium hyaluronate dry powder is first prepared by the method disclosed in the Chinese patent document CN 103923328A (application number 201410153564.9) entitled "High-quality cross-linked sodium hyaluronate gel and its preparation method". Sodium hyaluronate gel was combined, and then the gel was vacuum-dried at a temperature lower than 30°C to obtain a dry powder for future use.

[0036] ②Put the suspension obtained in step ① into a high-pressure homogenizer for 1-3 times of...

Embodiment 2)

[0045] The average particle diameter of the nano-crosslinked hyaluronic acid gel in this embodiment is 486 nm.

[0046] The rest of the preparation method of the above nano cross-linked hyaluronic acid is the same as the preparation method of the nano cross-linked hyaluronic acid in Example 1, the difference is:

[0047] What used in step ① is in the 30% acetone aqueous solution.

[0048] Step ② Send the suspension obtained in step ① into a high-pressure homogenizer for homogenization twice, and the pressure of the high-pressure homogenizer is 150Mpa.

Embodiment 3

[0049] (Example 3, Nano cross-linked sodium hyaluronate medical dressing)

[0050] The nano-crosslinked sodium hyaluronate dressing of this embodiment belongs to the second class of medical devices, including a carrier layer and a repair solution, the repair solution penetrates the carrier layer, and the weight percentage of each component in the repair solution is the hyaluronic acid composition 0.1% to 1% (0.2% in this embodiment), and the balance is PBS; the hyaluronic acid composition includes 25% to 30% (28% in this embodiment) of 100nm to 500nm nanotransplant Combined with sodium hyaluronate gel and the remaining amount of hyaluronic acid gel, the hyaluronic acid gel is composed of 10% to 20% (15% in this embodiment) hyaluronic acid gel with a molecular weight lower than 300,000 and 80% to 90% (85% in this embodiment) of hyaluronic acid gel with a molecular weight higher than 300,000, and the above contents all refer to mass percentages.

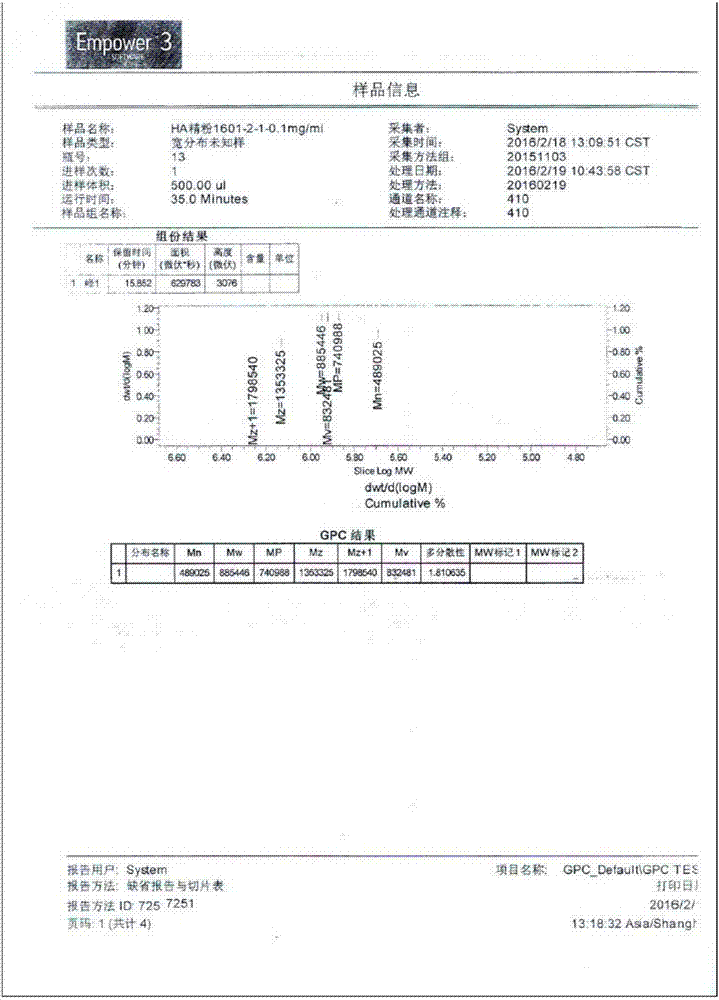

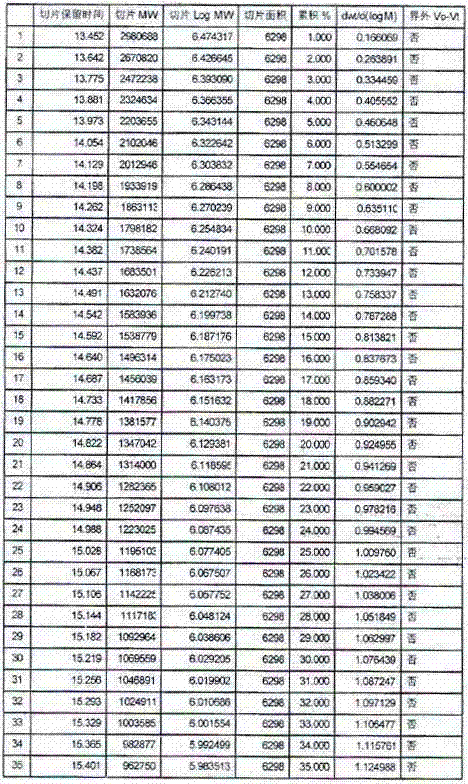

[0051] The molecular weight an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com