Preparation method of catalyst for methanol electrocatalytic reforming

A reforming catalyst and electrocatalysis technology, applied in the field of materials, can solve the problems that MOFs are rarely used in the field of catalysis, and achieve the effects of shortening the preparation time, making the preparation method simple and easy, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

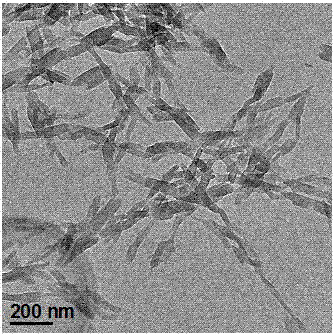

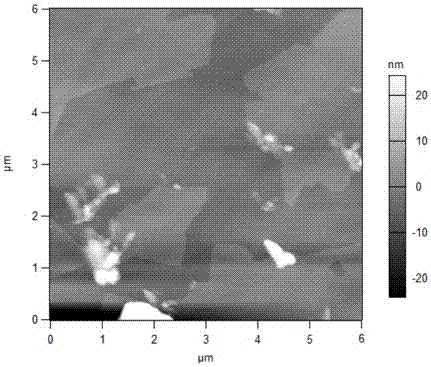

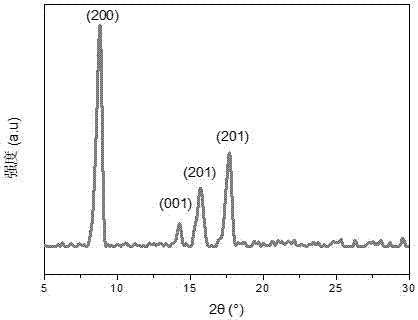

[0024] Measure the mixed solution of 2mL deionized water, 2mL ethanol and 32mL DMF in a 100mL blue cap bottle, then weigh 0.12g BDC and dissolve it in the mixed solution, then dissolve the same molar amount of CuCl2• 2H2O and CoCl2• 6H2O, add 0.8 mL of triethylamine, stirred rapidly for 5 minutes, screwed on the bottle cap and continued ultrasonic reaction for 8 hours (1600W, 40KHZ). The precursor obtained above was centrifuged, then washed 5 times with absolute ethanol, and CoCu-BDC was obtained by freeze-drying, and its TEM and AFM photos and XRD patterns were as follows: figure 1 , figure 2 as well as image 3 As shown, the structure of CoCu-BDC MOF nanosheets can be seen from the TEM image. Through the AFM test, the thickness of the ultra-thin MOF nanosheets is 3-5 nm, and the wide-angle XRD results are consistent with the structure of CoCu-BDC materials reported in the literature.

[0025] The obtained nanosheet MOF material and carbon black were mixed at a mass ratio ...

Embodiment 2

[0028] Measure the mixed solution of 2mL deionized water, 2mL ethanol and 32mL DMF in a 100mL blue cap bottle, then weigh 0.12gBDC and dissolve it in the mixed solution, then dissolve the same molar amount of CoCl2• 6H2O in it, then add 0.8mL triethyl Amine, stirred rapidly for 5 minutes, screwed on the bottle cap and continued ultrasonic reaction for 8 hours (1600W, 40KHZ). The precursor obtained above was centrifuged, washed five times with absolute ethanol, and CoCu-BDC was obtained by freeze-drying. The structure of the obtained nanosheet MOF material was characterized by TEM, SEM and XRD. The CoCu-BDC MOF nanosheet structure can be seen from the TEM image. Through AFM testing, the thickness of the ultrathin MOF nanosheet is 3-5 nm. The wide-angle XRD results are consistent with the structure of Co-BDC materials reported in the literature.

[0029] The obtained nanosheet MOF material and carbon black were mixed at a mass ratio of 1:1, dispersed in a mixed solution of deio...

Embodiment 3

[0032] Measure the mixed solution of 2mL deionized water, 2mL ethanol and 32mL DMF in a 100mL blue cap bottle, then weigh 0.12gBDC and dissolve it in the mixed solution, then dissolve the same molar amount of CuCl2• 2H2O in it, then add 0.8mL triethyl Amine, stirred rapidly for 5 minutes, screwed on the bottle cap and continued ultrasonic reaction for 8 hours (1600W, 40KHZ). The precursor obtained above was centrifuged, washed five times with absolute ethanol, and CoCu-BDC was obtained by freeze-drying. The structure of the obtained nanosheet MOF material was characterized by TEM, SEM and XRD. The coiled structure of CoCu-BDC MOF nanosheets can be seen from the TEM image. Through AFM test, the thickness of the ultrathin MOF nanosheets is 3-5 nm , and its wide-angle XRD results are consistent with the structure of Cu-BDC materials reported in the literature.

[0033] The obtained nanosheet MOF material and carbon black were mixed at a mass ratio of 1:1, dispersed in a mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com