Double-membrane wastewater treatment system based on fully-automatic ultrafiltration and reverse osmosis (RO) and a method

A waste water treatment system, waste water treatment technology, applied in the direction of filtration treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of endangering production safety, harsh use conditions, easy to cause fire, etc., to reduce the cost of waste liquid treatment , Guaranteed flux and life, convenient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

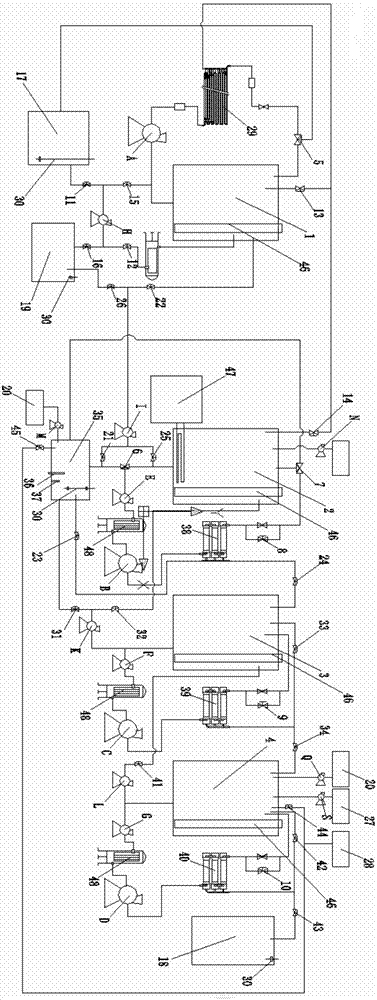

[0026] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] A double-membrane wastewater treatment system based on fully automatic ultrafiltration + RO reverse osmosis, including a raw liquid pool 17, a clear liquid storage pool 18, a concentrated liquid pool 19 and a circulation device. The first-level circulation loop, the second-level circulation loop, the third-level circulation loop and the fourth-level circulation loop, each circulation loop includes a circulating water tank and a membrane filter device.

[0028] A double-membrane wastewater treatment method based on fully automatic ultrafiltration+RO reverse osmosis, comprising the following steps:

[0029] S1: First, set the number of times of work through the PLC control system, and then the raw liquid in the raw liquid pool 17 is opened through the first-stage liquid intake valve 11 in the primary circulation circuit, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com