A kind of flexible graphene-based composite film and its preparation method and application as electromagnetic shielding material

A technology of flexible graphite and composite materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve problems such as poor conductivity, achieve high conductivity, good electromagnetic shielding performance, and uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

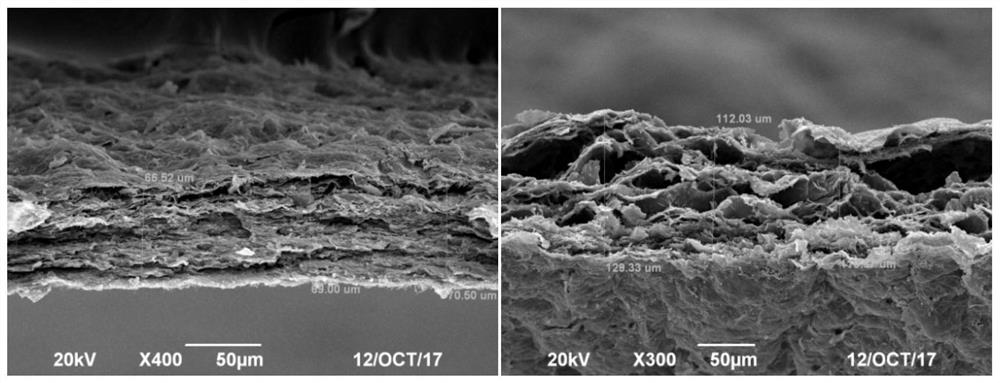

Image

Examples

Embodiment 1

[0050] (1) Weigh 30 mg of graphene oxide, add it to a beaker, add 160 ml of absolute ethanol, and work for 15 minutes under the cell pulverizer to obtain a uniform dispersion. Then add 33 wt% of silver-loaded carbon nanofibers and 17 wt% of magnetic ferric iron tetroxide powder according to the mass fraction, and continue to disperse the mixed solution with a cell pulverizer.

[0051] (2) Evenly disperse 30 mg of sodium alginate powder into 40 ml of distilled water, mix with the dispersion in step (1), and then work for 15 minutes under the cell pulverizer.

[0052] (3) The mixed solution obtained in the step (2) is vacuum filtered to obtain a composite film, which is left to dry at normal temperature and pressure for 12 hours.

[0053] (4) Remove the film obtained in step (3), seal it and place it in a polytetrafluoroethylene-lined stainless steel autoclave to which 4 drops of hydrazine hydrate has been added dropwise, heat it to 100°C and keep it at a constant temperature fo...

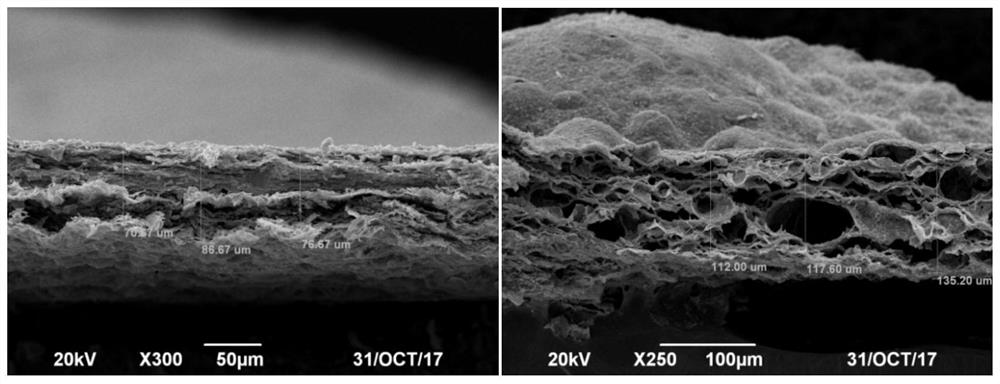

Embodiment 2

[0056] (1) Weigh 30 mg of graphene oxide, add it to a beaker, add 160 ml of absolute ethanol, and work for 15 minutes under the cell pulverizer to obtain a uniform dispersion. Then add 43wt% of silver-loaded carbon nanofibers and 14wt% of magnetic ferric iron tetroxide powder according to the mass fraction, and continue to disperse the mixed solution with a cell pulverizer.

[0057] (2) Evenly disperse 30 mg of sodium alginate powder into 40 ml of distilled water, mix with the dispersion in step (1), and then work for 15 minutes under the cell pulverizer.

[0058] (3) The mixed solution obtained in the step (2) is vacuum filtered to obtain a composite film, which is left to dry at normal temperature and pressure for 12 hours.

[0059] (4) Remove the film obtained in step (3), seal it and place it in a polytetrafluoroethylene-lined stainless steel autoclave to which 4 drops of hydrazine hydrate has been added dropwise, heat it to 110°C and keep it at a constant temperature for ...

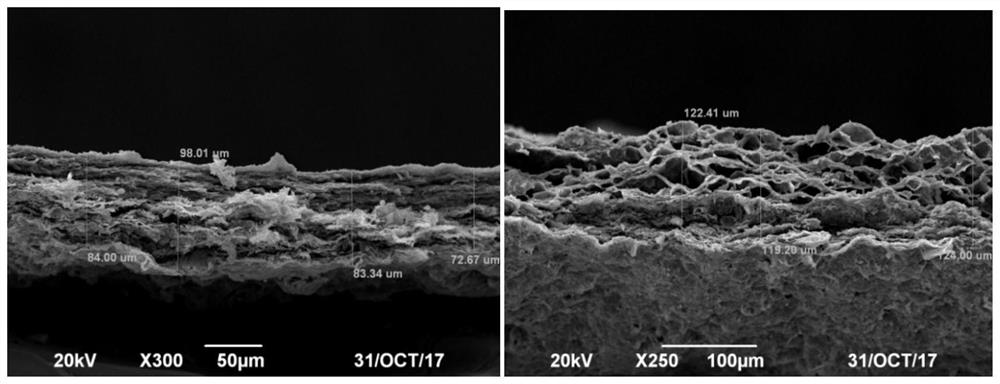

Embodiment 3

[0062] (1) Weigh 30 mg of graphene oxide, add it to a beaker, add 160 ml of absolute ethanol, and work for 15 minutes under the cell pulverizer to obtain a uniform dispersion. Then add 33wt% of silver-loaded carbon nanofibers and 33wt% of magnetic ferric iron tetroxide powder according to the mass fraction, and continue to disperse the mixed solution with a cell pulverizer.

[0063] (2) Evenly disperse 30 mg of sodium alginate powder into 40 ml of distilled water, mix with the dispersion in step (1), and then work for 15 minutes under the cell pulverizer.

[0064] (3) The mixed solution obtained in the step (2) is vacuum filtered to obtain a composite film, which is left to dry at normal temperature and pressure for 12 hours.

[0065] (4) Remove the film obtained in step (3), seal it and place it in a polytetrafluoroethylene-lined stainless steel autoclave to which 4 drops of hydrazine hydrate has been added dropwise, heat it to 120°C and keep it at a constant temperature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com