Method for inhibiting oxidation of pyrite in biological metallurgy process

A biometallurgy and pyrite technology is applied in the field of inhibiting pyrite oxidation, which can solve the problems of increased copper production cost, large consumption of extractant, and high environmental protection pressure, so as to reduce living space, inhibit excessive oxidation, and enhance the use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

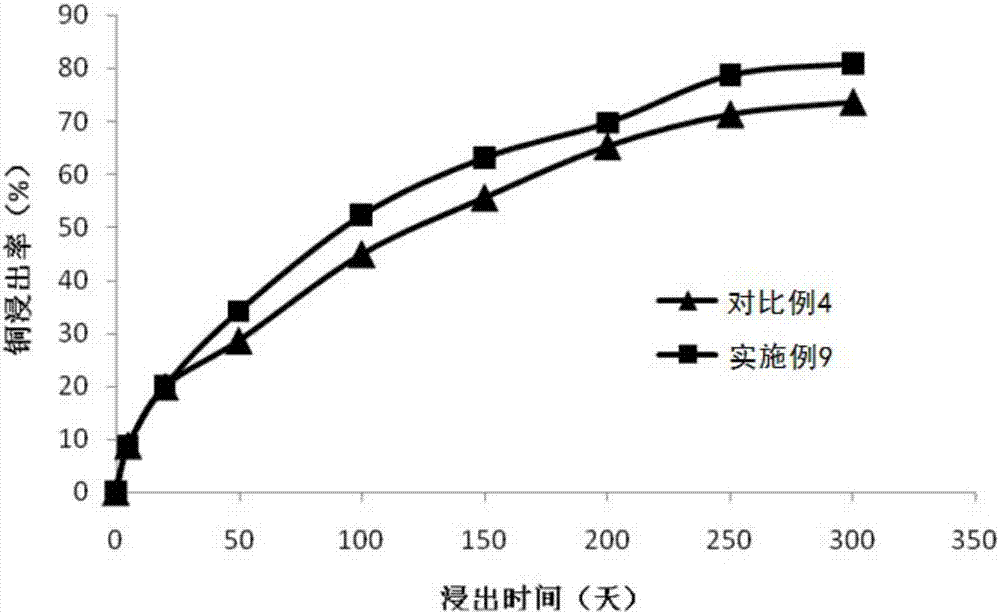

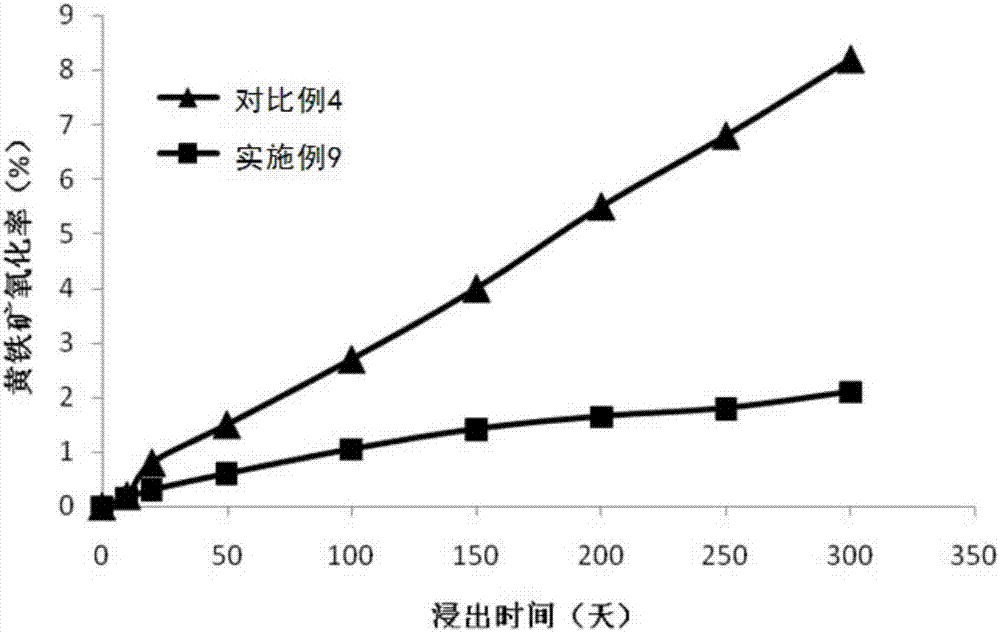

Embodiment 1

[0038] In the low-grade copper ore bioheap leaching test, the ore composition was Cu 0.35%, Fe 5.19%, and reduced S6.18%. The main copper minerals in the ore are chalcocite, copper blue and sulphur arsenic, among which chalcocite accounts for more than 90%, and the content of pyrite is 9.2%. The main gangue minerals are feldspar, quartz and sericite. The ore is crushed to a particle size of less than 50mm, and the inhibitor powder is evenly mixed into the inhibitor powder. The inhibitor is composed of: polyacrylamide, with a dosage of 200mg / kg ore; sodium benzoate, with a dosage of 500mg / kg ore; sodium metabisulfite, with a dosage 200mg / kg ore; acetic acid, the use dose is 1000mg / kg ore. After 150 days of leaching, the copper leaching rate was 86.6%, and the pyrite oxidation rate was 2.0%.

Embodiment 2

[0040] The only difference from Example 1 is that the inhibitor does not contain acetic acid. After 150 days of leaching, the copper leaching rate was 85.0%, and the pyrite oxidation rate was 3.4%.

Embodiment 3

[0042] The only difference from Example 1 is that the inhibitor does not contain sodium metabisulfite. After 150 days of leaching, the copper leaching rate was 85.5% and the pyrite oxidation rate was 3.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com