Graphene nanocomposite material and preparation method thereof

A nano-composite material and graphene technology, applied in the field of graphene nano-composite materials and its preparation, can solve the unsatisfactory, energy supply that can only be maintained for a period of time, the energy storage effect of the electronic cloth has not been improved, and the flexibility is not good. It can reduce the phenomenon of agglomeration, improve the efficiency of energy storage, and achieve the effect of reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

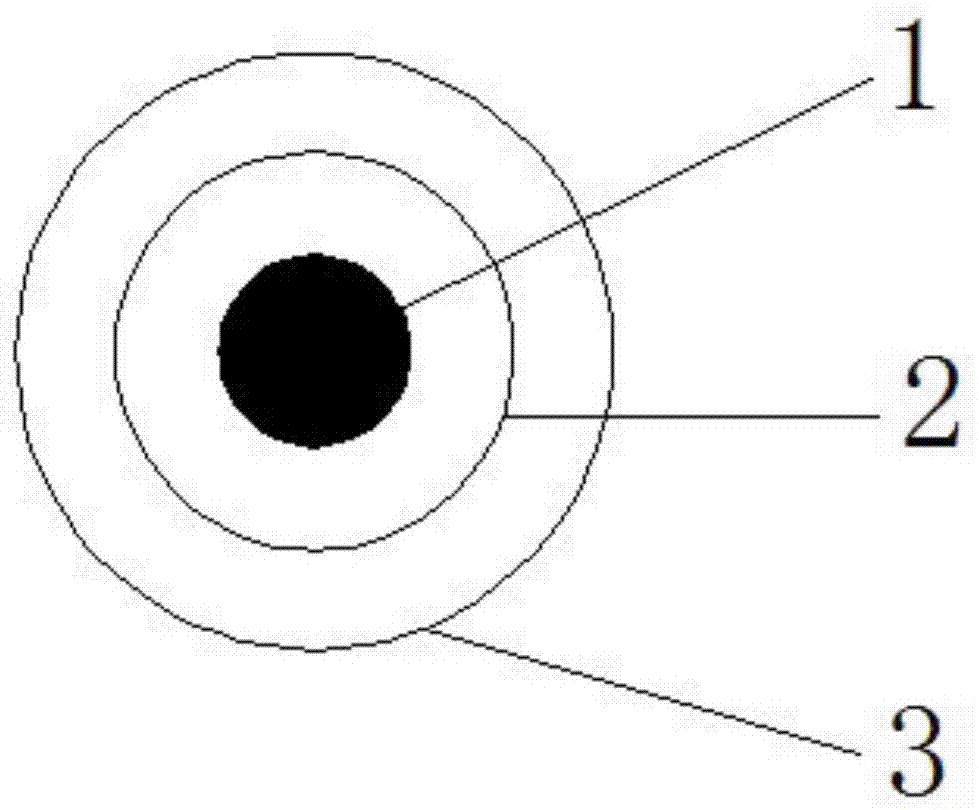

[0023] A graphene nanocomposite material proposed by the present invention is braided by graphene nanofibers, and gallium oxide chips are inserted during the weaving process. The gallium oxide chips are prefabricated into filaments and programmed before use. program, the graphene nanofiber is composed of a conductive rib layer 1, an insulating layer 2 and a graphene layer 3, and the insulating layer 2 is coated on the conductive rib layer 1, and the graphene layer 3 is coated on the insulating layer 2 , the conductive tendon layer 1 is copper wire, and the graphene layer 3 is composed of graphene, polyurethane, ethanol, acetone, nano-silver with a mass ratio of 0.02:50:58:30:0.1:0.3:0.1:0.02:0.01 , nano-copper, nano-aluminum, titanium and rare earth metals;

[0024] The preparation method of graphene nano composite material comprises the following steps:

[0025] S1. Preparation of raw materials: according to the mass ratio of graphene, polyurethane, ethanol, acetone, nano-si...

Embodiment 2

[0030] A graphene nanocomposite material proposed by the present invention is braided by graphene nanofibers, and gallium oxide chips are inserted during the weaving process. The gallium oxide chips are prefabricated into filaments and programmed before use. program, the graphene nanofiber is composed of a conductive rib layer 1, an insulating layer 2 and a graphene layer 3, and the insulating layer 2 is coated on the conductive rib layer 1, and the graphene layer 3 is coated on the insulating layer 2 , the conductive rib layer 1 is a mixture of copper wire and silver wire, and the graphene layer 3 is composed of graphene, polyurethane, ethanol with a mass ratio of 0.03:55:60:28:0.1:0.2:0.2:0.01:0.015 , acetone, nano-silver, nano-copper, nano-aluminum, titanium and rare earth metals;

[0031] The preparation method of graphene nano composite material comprises the following steps:

[0032] S1. Preparation of raw materials: according to the mass ratio of graphene, polyurethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com