Aflatoxin-removed feed prepared from kitchen waste and production technology of aflatoxin-removed feed

A technology for aflatoxin and kitchen waste, applied in animal feed, animal feed, food processing, etc., can solve the problems of reduced economic and practical value, large feed safety problems, accumulation of aflatoxin, etc., and reduce the residence time. , reduce the content, accelerate the effect of intestinal peristalsis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

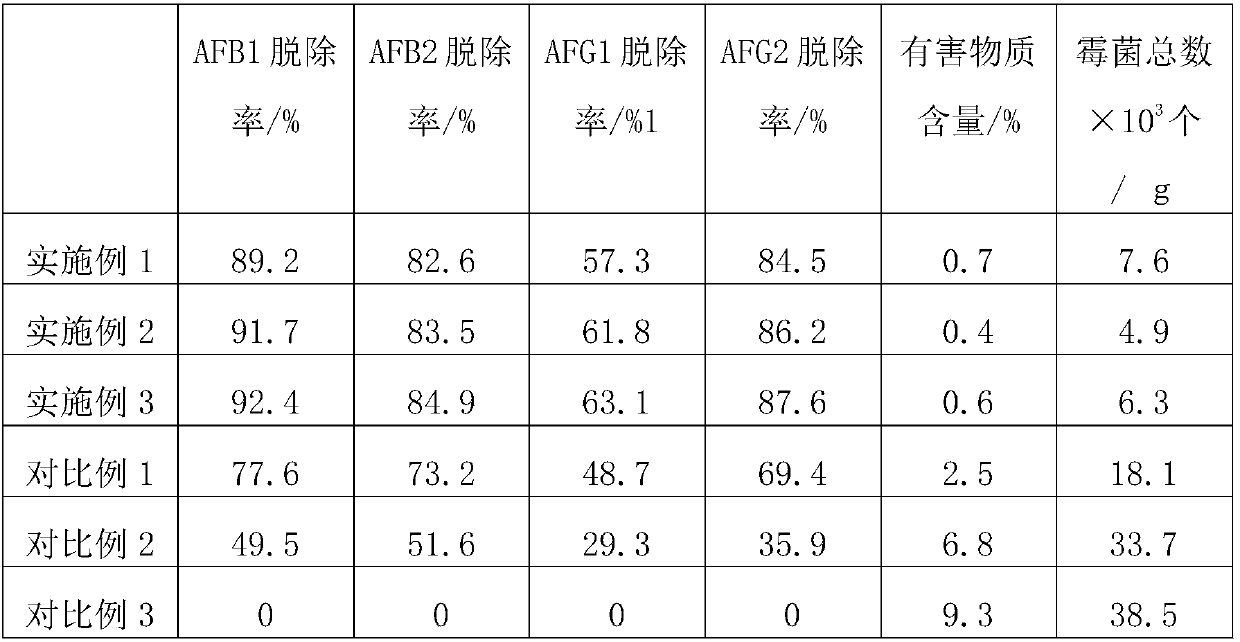

Embodiment 1

[0025] Step 1: Pre-treat the food waste so that the water content is ≦40% and the protein content is ≧25%;

[0026] Step 2: crush 40% of kitchen waste and 30% of wheat bran, and pass through a 25-mesh sieve to obtain a fermentation substrate;

[0027] Step 3: Mixing Bacillus subtilis, Lactobacillus casei and Flavobacterium aurantiacus according to the weight ratio of 1.5:2:1.8 to obtain mold-removing bacteria;

[0028] Step 4: At 35°C, after passing the air through the microporous ultrafiltration membrane, continuously pass it into the fermentation substrate, and mix it with 4% citric acid to adjust the pH to 6.3, add 10% mold removal bacteria, and stir for 30 minutes every 2 days , fermented for 10 days to obtain roughage;

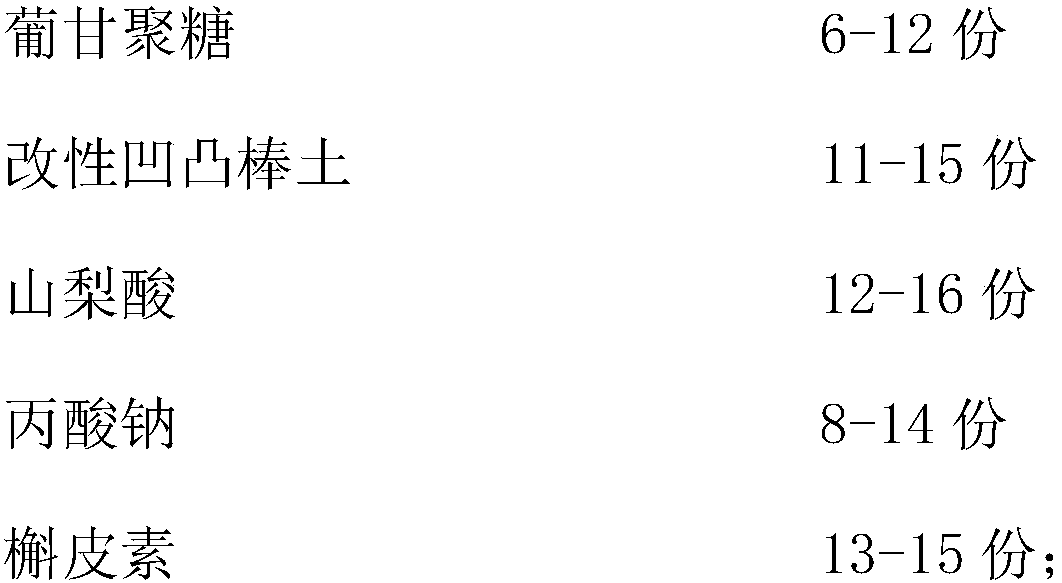

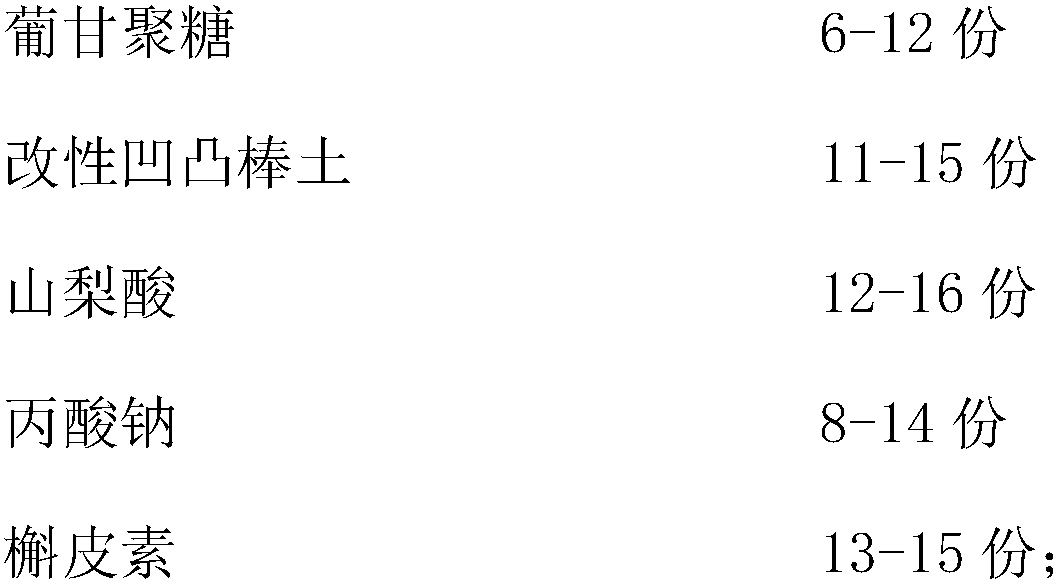

[0029] Step 5: After immersing 11-15 parts of attapulgite in dilute hydrochloric acid with a concentration of 0.5 mol / L for 3 hours, the modified attapulgite is obtained, and mixed with 6 parts of glucomannan, 12 parts of sorbic acid, 8 parts Sodium pro...

Embodiment 2

[0032] The operation is the same as in Example 1, wherein the mass percentages of food waste and wheat bran in step 2 are 50% and 45% respectively, and passed through a 37.5 mesh sieve; The temperature is 37°C, the pH is 6.5, the mass percentages of citric acid and mold-removing bacteria are 6% and 12.5% respectively, and fermentation is carried out for 12 days; The parts by weight of the components are 9 parts, 13 parts, 14 parts, 11 parts and 14 parts; in the step 6, the mass percentages of the mildew-removing agent, tea polyphenols and trace elements are 10%, 4.5%, and 0.2% respectively.

Embodiment 3

[0034] The operation is the same as in Example 1, wherein the mass percentages of food waste and wheat bran in step 2 are 60% and 37.5% respectively, and passed through a 50-mesh sieve; The temperature is 38°C, the pH is 6.8, the mass percentages of citric acid and mold-removing bacteria are 8% and 15% respectively, and fermentation is carried out for 15 days; in step 5, the concentration of dilute hydrochloric acid is 1mol / L, the soaking time is 6h, and the weight of each component of the mold-removing agent is The number of parts is 12 parts, 15 parts, 16 parts, 14 parts and 15 parts; in the step 6, the mass percentages of mold remover, tea polyphenols and trace elements are 12%, 6%, 0.3% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com