Method for preparing nano-scale reproducible antibacterial medical porous titanium-magnesium skeleton material

A porous titanium, nano-scale technology, applied in medical science, prosthesis, etc., can solve the problems of reducing the strength of titanium, bio-affinity and corrosion resistance, not being widely used in clinical medicine, and the pore size and shape cannot be controlled. , to achieve good antibacterial and antivirus performance, good renewable performance, and improve the effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

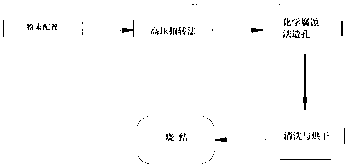

[0024] The diagram of the steps of the implementation case is as follows: image 3 .

[0025] 1. Selection of powder: choose metal titanium powder, magnesium powder, silver powder, zinc powder, calcium powder, potassium powder with a content greater than 99.99%, and non-metallic silicon powder and white phosphorus powder with a content greater than 99.99%.

[0026] 2. Powder configuration: The mass fraction of titanium is 55%, the mass fraction of magnesium is 16%, the mass fraction of silver is 1%, the mass fraction of zinc is 0.3%, the mass fraction of calcium is 2%, and the mass fraction of potassium 0.7%, the mass fraction of silicon is 24%, the mass fraction of phosphorus is 1%, and the powder mixture is 500g.

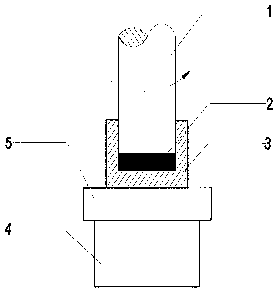

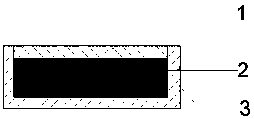

[0027] 3. Preliminary twisting process: place a certain mass of the metal powder mixture 2 prepared in the 2 process on the figure 1 of Die 3, using figure 1 The torque of the indenter 1 is set to 900Nm, the rotation speed of the indenter is 2r / min, the twist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com