Epoxybutane composition and preparation method thereof

A technology of butylene oxide and isobutane oxide, which is applied in the direction of organic chemistry, can solve the problems of limited output, long separation process, and low purity, and achieve the effects of low raw material cost, high product purity, and environmentally friendly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

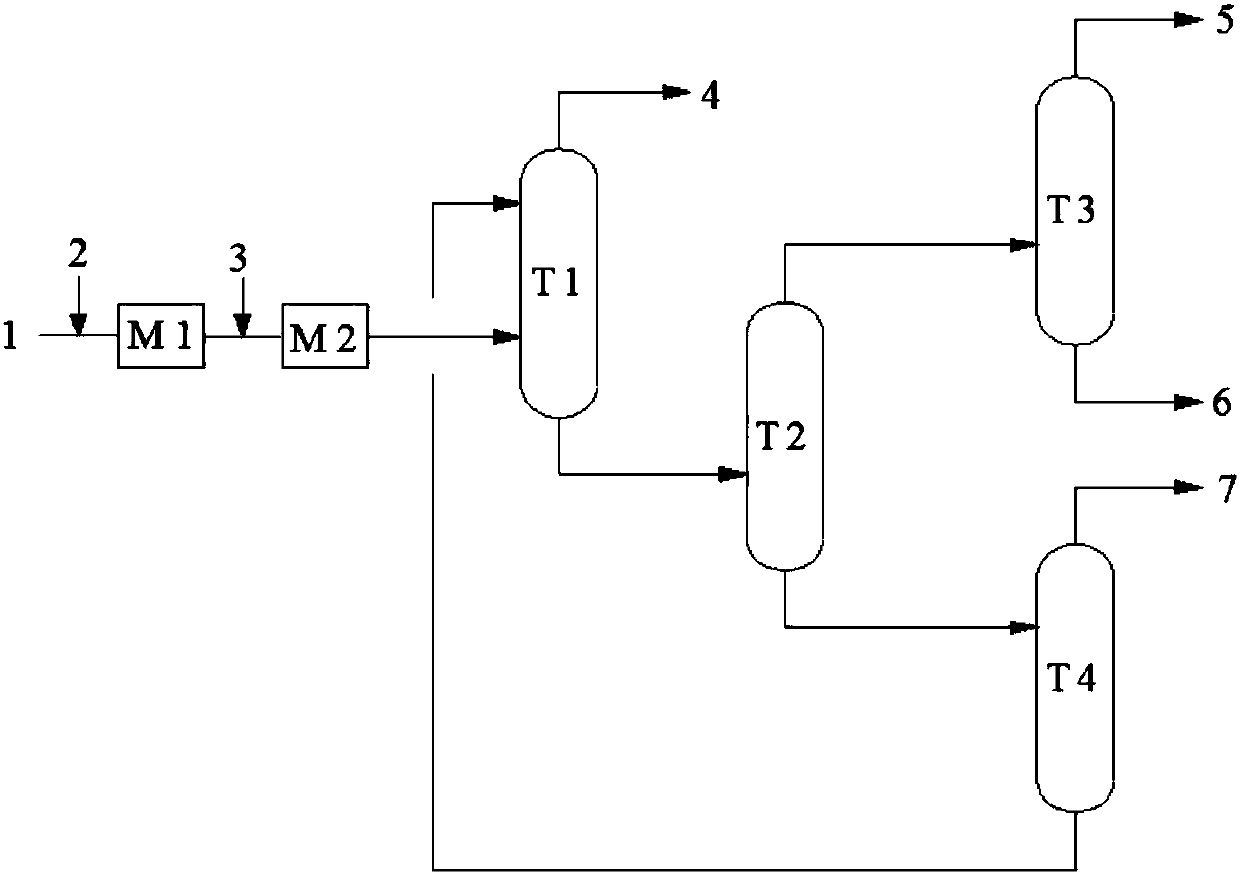

Method used

Image

Examples

Embodiment 1

[0053] Cumene undergoes peroxidation reaction with air to generate cumene hydroperoxide (CHP), and CHP undergoes epoxidation reaction with butene under the action of Ti-HMS catalyst to generate butylene oxide and α,α-di Methyl benzyl alcohol. In the presence of a proprietary palladium / carbon catalyst, α,α-dimethylbenzyl alcohol undergoes a hydrogenolysis reaction with hydrogen to generate cumene, and then cumene is returned to the peroxidation unit as a raw material for the preparation of CHP for recycling.

[0054] The reaction temperature of the epoxidation reaction is 100°C, the reaction pressure is 3MPa, the molar ratio of butene to CHP is 5:1, and the space velocity of CHP is 5h -1 .

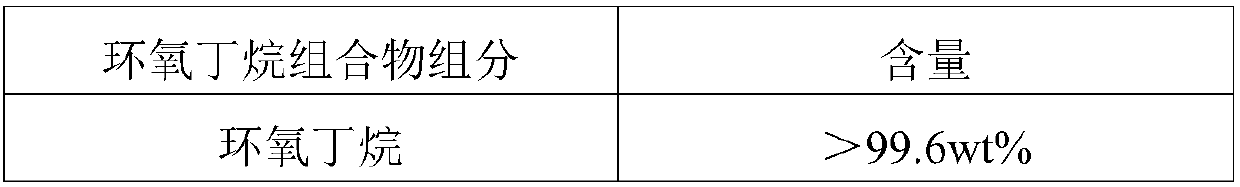

[0055] The butene epoxidation product is recovered butene, and the crude butylene oxide solution after separation of α,α-dimethylbenzyl alcohol contains 97.3wt% butylene oxide, water, propionaldehyde, acetone, butyraldehyde, epoxy Isobutane, methanol, methyl formate, C 5 ~C 8 Hydrocarbo...

Embodiment 2

[0062] Embodiment is the same as embodiment 1.

[0063] The difference is that the catalyst for the epoxidation reaction is Ti-KIT, the reaction temperature is 120°C, the reaction pressure is 3.5MPa, the molar ratio of butene to CHP is 6:1, and the space velocity of CHP is 4h -1 .

[0064] The butylene epoxidation product is recovered butene, and the crude butylene oxide solution after separating α,α-dimethylbenzyl alcohol contains 95.7wt% butylene oxide, water, propionaldehyde, acetone, butyraldehyde, epoxy Isobutane, methanol, methyl formate, C 5 ~C 8 Hydrocarbon impurities totaled 4.3 wt%.

[0065] The butylene oxide composition is obtained by refining crude butylene oxide. Among them, the extractant is n-heptane, the theoretical plate number of the extraction tower is 70, the operating pressure is 160kPa, the operating temperature of the tower kettle is 120°C, the reflux ratio is 40, and the solvent ratio is 6; the theoretical plate number of the separation tower It i...

Embodiment 3

[0071] Embodiment is the same as embodiment 1.

[0072] The difference is that the catalyst for the epoxidation reaction is Ti-SiO 2 , the reaction temperature is 110°C, the reaction pressure is 3.2MPa, the molar ratio of butene to CHP is 8:1, and the CHP space velocity is 4.5h -1 .

[0073] The butene epoxidation product is recovered butene, and the crude butylene oxide solution after separation of α,α-dimethylbenzyl alcohol contains 96.5wt% butylene oxide, water, propionaldehyde, acetone, butyraldehyde, epoxy Isobutane, methanol, methyl formate, C 5 ~C 8 Hydrocarbon impurities totaled 3.5 wt%.

[0074] The butylene oxide composition is obtained by refining crude butylene oxide. Among them, the extraction agent is n-octane, the theoretical plate number of the extraction tower is 65, the operating pressure is 150kPa, the operating temperature of the tower kettle is 117°C, the reflux ratio is 80, and the solvent ratio is 8; the theoretical plate number of the separation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com