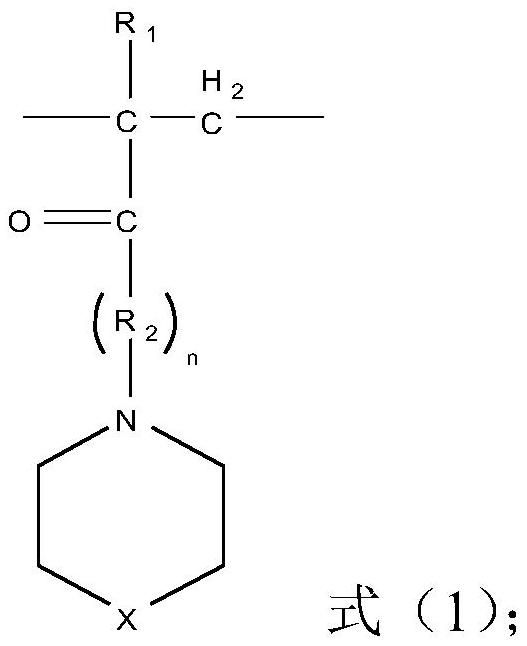

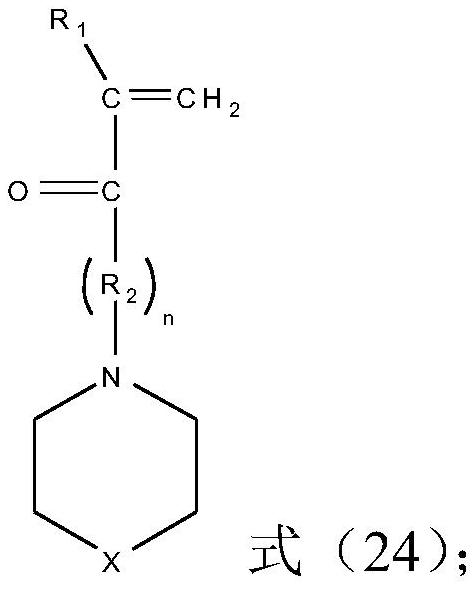

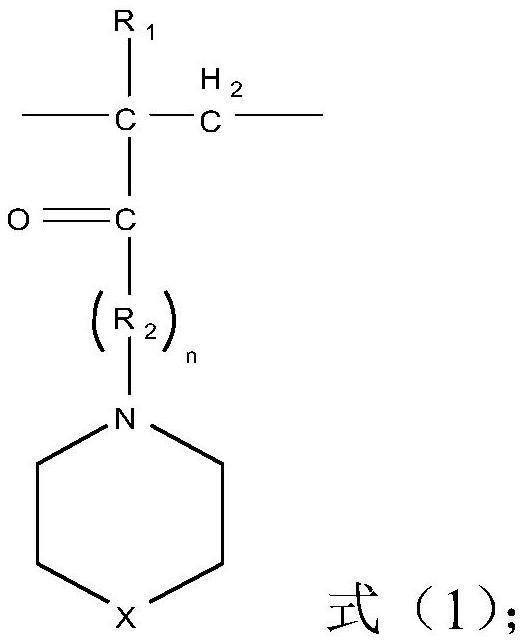

A kind of alkali-soluble resin polymer, its preparation method and photosensitive resin composition

A technology of alkali-soluble resin and photosensitive resin, which is applied in the field of alkali-soluble resin polymer and photosensitive resin composition, and can solve the problems of reduced stability of resin composition, insufficient pixel line width, precipitation of precipitates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of the above-mentioned color filter may include: coating the above-mentioned photosensitive resin composition on a substrate, and sequentially undergoing steps of pre-baking, exposure, development and post-baking to obtain the color filter.

[0067] The present disclosure is further illustrated by examples below, but the present disclosure is not limited thereby.

Embodiment 1

[0069] In a 200mL flask, add 28g monomer acryloyl morpholine (Bainwei), 37g benzyl methacrylate, 20g N-phenylmaleimide, 240g propylene glycol methyl ether acetate, 0.3mL molecular weight regulator, nitrogen protection, Heat the system to 80°C, and add 17 g of propylene glycol methyl ether acetate solution and 15 g of methacrylic acid in 1.0 g of azobisisobutyronitrile into the three-necked flask dropwise within 30 minutes using a constant pressure dropping funnel , followed by constant temperature stirring for 3 hours, the temperature was lowered to room temperature, and the solvent was removed to obtain the alkali-soluble resin polymer B1. The weight-average molecular weight of the polymer measured by GPC was 8360, the molecular weight distribution was 2.13, and the acid value was 106.3 mgKOH / g.

Embodiment 2

[0071] In a 200mL flask, add 28g monomer acryloyl morpholine (Bainwei), 34g benzyl methacrylate, 20g N-phenylmaleimide, 240g propylene glycol methyl ether acetate, 0.3mL molecular weight regulator, nitrogen protection, Heat the system to 85°C, and under stirring, use a constant pressure dropping funnel to drop 17g of propylene glycol methyl ether acetate solution and 18g of methacrylic acid dissolved in 1.05g of azobisisobutyronitrile into the three-necked flask within 30min. , followed by constant temperature stirring for 3 hours, the temperature was lowered to room temperature, and the solvent was removed to obtain the alkali-soluble resin polymer B2. The weight-average molecular weight of the polymer measured by GPC was 8100, the molecular weight distribution was 1.95, and the acid value was 113.2 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com