A kind of silk nanofiber membrane and its preparation method and application in supercapacitor

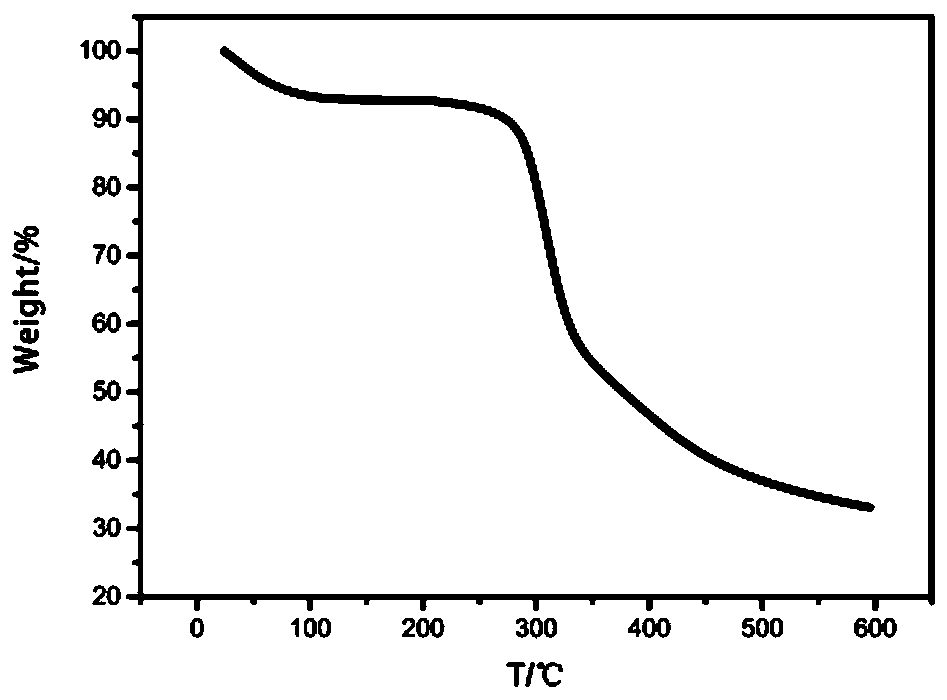

A nanofiber film and silk technology, applied in the field of materials, can solve the problems of silk fibroin products such as poor mechanical properties, poor electrolyte wettability, poor thermal dimensional stability, etc., to achieve excellent thermal stability and mechanical properties, good electrolyte Affinity, the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Mix 0.1g of degummed silk with urea / guanidine hydrochloride (molar ratio 1:1) deep eutectic solvent (mass ratio of degummed silk to deep eutectic solvent 1:100), then place the whole system at 80°C and stir for 24h, get a slurry;

[0045] Add 2000 mL of deionized water into 50 mL of the slurry, stir evenly, vacuum filter (vacuum degree is 0.1 MPa), wash with a certain amount of water to remove the deep eutectic solvent to obtain pretreated silk;

[0046] Add the pretreated silk to a certain amount of deionized water (the mass ratio of pretreated silk to deionized water is 1:100), and stir evenly; ultrasonicate the obtained suspension for 4 hours, and the ultrasonic power is 400W; centrifuge the ultrasonically obtained silk suspension , the centrifugal speed is 1000RPM, the time is 30min, the supernatant is collected, and the silk nanofiber dispersion is obtained;

[0047] The dispersion liquid was vacuum filtered and dried at 60° C. for 12 hours to obtain a silk nanofi...

Embodiment 2

[0050] Mix 0.1g of degummed silk with urea / guanidine hydrochloride (molar ratio 1:1) deep eutectic solvent (mass ratio of degummed silk to deep eutectic solvent 1:100), then place the whole system at 100°C and stir for 24h, get a slurry;

[0051] Add 2000 mL of deionized water into 50 mL of the slurry, stir evenly, vacuum filter (vacuum degree is 0.1 MPa), wash with a certain amount of water to remove the deep eutectic solvent to obtain pretreated silk;

[0052] Add the pretreated silk to a certain amount of deionized water (the mass ratio of pretreated silk to deionized water is 1:100), and stir evenly;

[0053] Sonicate the obtained suspension for 4 hours with an ultrasonic power of 400W; centrifuge the ultrasonicated silk suspension at a speed of 1000 RPM for 30 minutes, collect the supernatant to obtain a silk nanofiber dispersion;

[0054] The dispersion liquid was vacuum filtered and dried at 60° C. for 12 hours to obtain a silk nanofiber membrane.

[0055] The thickne...

Embodiment 3

[0057] Mix 0.1g of degummed silk with choline chloride / urea (molar ratio 1:2) deep eutectic solvent (mass ratio of degummed silk to deep eutectic solvent 1:100), and then place the whole system at 100°C and stir for 24h , to obtain slurry;

[0058] Add 2000 mL of deionized water into 50 mL of the slurry, stir evenly, vacuum filter (vacuum degree is 0.1 MPa), wash with a certain amount of water to remove the deep eutectic solvent to obtain pretreated silk;

[0059] Add the pretreated silk to a certain amount of deionized water (the mass ratio of pretreated silk to deionized water is 1:100), and stir evenly;

[0060] Sonicate the obtained suspension for 4 hours with an ultrasonic power of 400W; centrifuge the ultrasonicated silk suspension at a speed of 2000 RPM for 20 minutes, collect the supernatant to obtain a silk nanofiber dispersion;

[0061] The dispersion liquid was vacuum filtered and dried at 60° C. for 12 hours to obtain a silk nanofiber membrane.

[0062] The thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com