Manufacturing method of silicon electrode for lithium ion battery based on selective melting technology

A silicon electrode and lithium battery technology, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as cracks on the electrode surface and electrode failure, and achieve the effect of fine structure and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

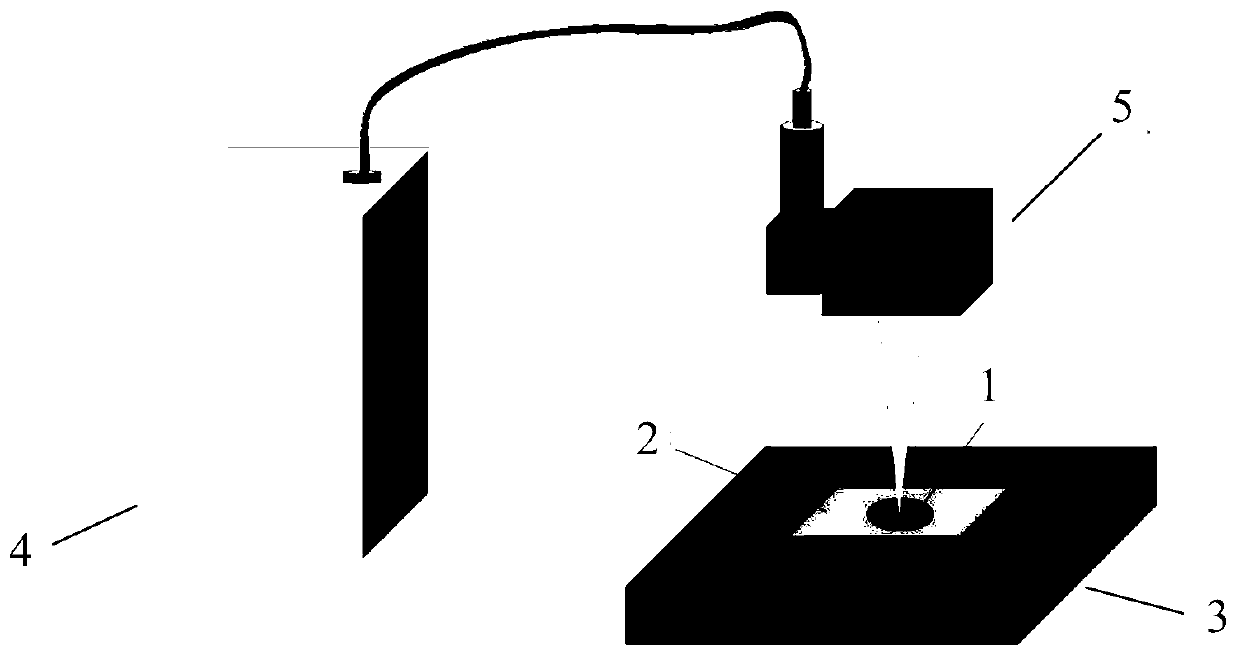

Method used

Image

Examples

Embodiment 1

[0049] 1. Raw materials:

[0050] (1) Pure copper: the purity is higher than 99.99%; Al-Si powder: the particle size is 30-80 μm, and the powder ratio is 50wt% Si;

[0051] (2) Solvent: alcohol solution;

[0052] (3) Etching solution: 3mol / L HCl solution.

[0053] 2. Manufacturing method

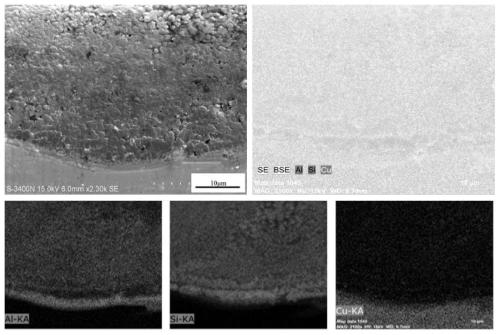

[0054] (1) Pre-place the powder on the copper current collector, use the YLS-3000 fundamental mode fiber laser to clad the aluminum-silicon powder to prepare the electrode precursor, laser power: 400W, scanning speed: 1500mm / s, laser spot: 100μm, scanning interval : 50 μm. A precursor alloy with a diameter of 8 mm and a thickness of about 50 μm was obtained. Example 1 Precursor alloy section SEM diagram and EDS element distribution diagram are as follows image 3 shown.

[0055] (2) Dealloying the precursor alloy with 3mol / L HCl solution for 4h, the cross-section and surface SEM images of the porous silicon electrode after dealloying in Example 1 are as follows Figure 4 shown. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com