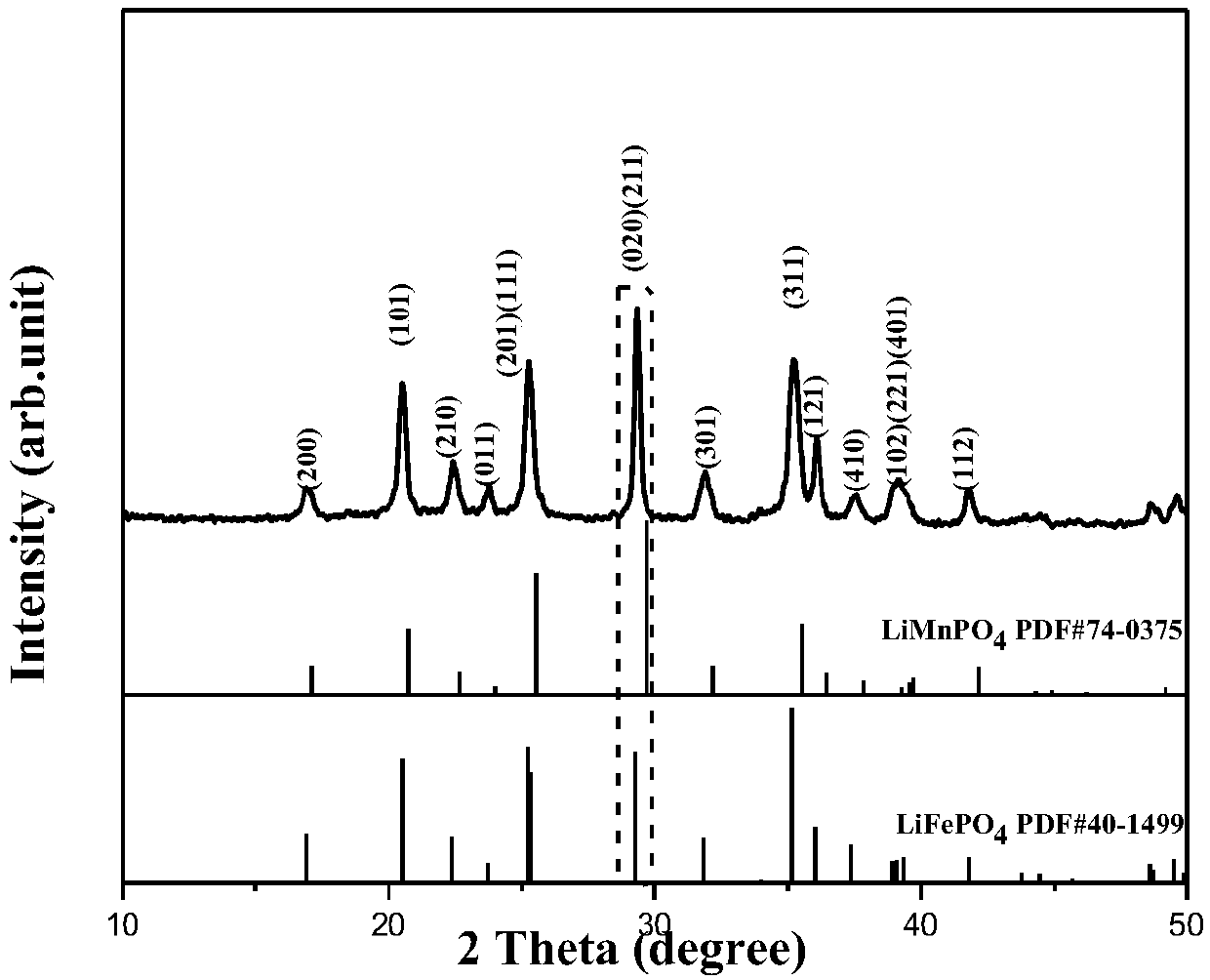

Preparation method of carbon-coated lithium iron manganese phosphate graphene composite nanomaterial

A technology of graphene composite and lithium iron phosphate, which is applied in the direction of graphene, nanotechnology for materials and surface science, nanocarbon, etc., can solve difficult problems such as positive electrode materials, and achieve compact structure, good stability, and full The effect of excellent discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a carbon-coated lithium iron phosphate lithium manganese graphene composite nanomaterial, comprising the following steps:

[0031] step one:

[0032] First measure concentrated sulfuric acid, then weigh graphite, sodium nitrate and potassium permanganate with a mass ratio of 1-2:1-2:3-5, wherein the total mass of graphite, sodium nitrate and potassium permanganate accounts for The mass fraction of 20%-30%, and then sequentially add concentrated sulfuric acid, graphite, sodium nitrate and potassium permanganate into the container to mix evenly and react at the first preset temperature for the first preset time, and then at the second preset temperature The first mixture is obtained after being left at the temperature for a second preset time, and then deionized water is added to the first mixture to react at a third preset temperature for a third preset time to obtain a second mixture, wherein the first mixture and the deioni...

Embodiment

[0051] step one:

[0052] First measure concentrated sulfuric acid, then weigh graphite, sodium nitrate and potassium permanganate with a mass ratio of 1:1:3, wherein the total mass of graphite, sodium nitrate and potassium permanganate accounts for 20% of the mass fraction of concentrated sulfuric acid, Then add concentrated sulfuric acid, graphite, sodium nitrate and potassium permanganate into the container in order to mix evenly and react at 10°C for 2h, then place it at 30°C for 0.5h to obtain the first mixture, and then add to the first mixture Ionized water was reacted at 90°C for 0.5h to obtain the second mixture, wherein the mass ratio of the first mixture to deionized water was 1:1, and then continue to take the total amount of concentrated sulfuric acid, graphite, sodium nitrate and potassium permanganate Hydrogen peroxide with a mass fraction of 25% was added to the second mixture, followed by washing with dilute hydrochloric acid and deionized water with a concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com