Preparation method of piezoelectric ceramic/bone cement biological piezoelectric composite material

A technology of piezoelectric composite materials and piezoelectric ceramics, applied in ceramic products, tissue regeneration, application, etc., can solve problems such as poor bone conductivity and high piezoelectric phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

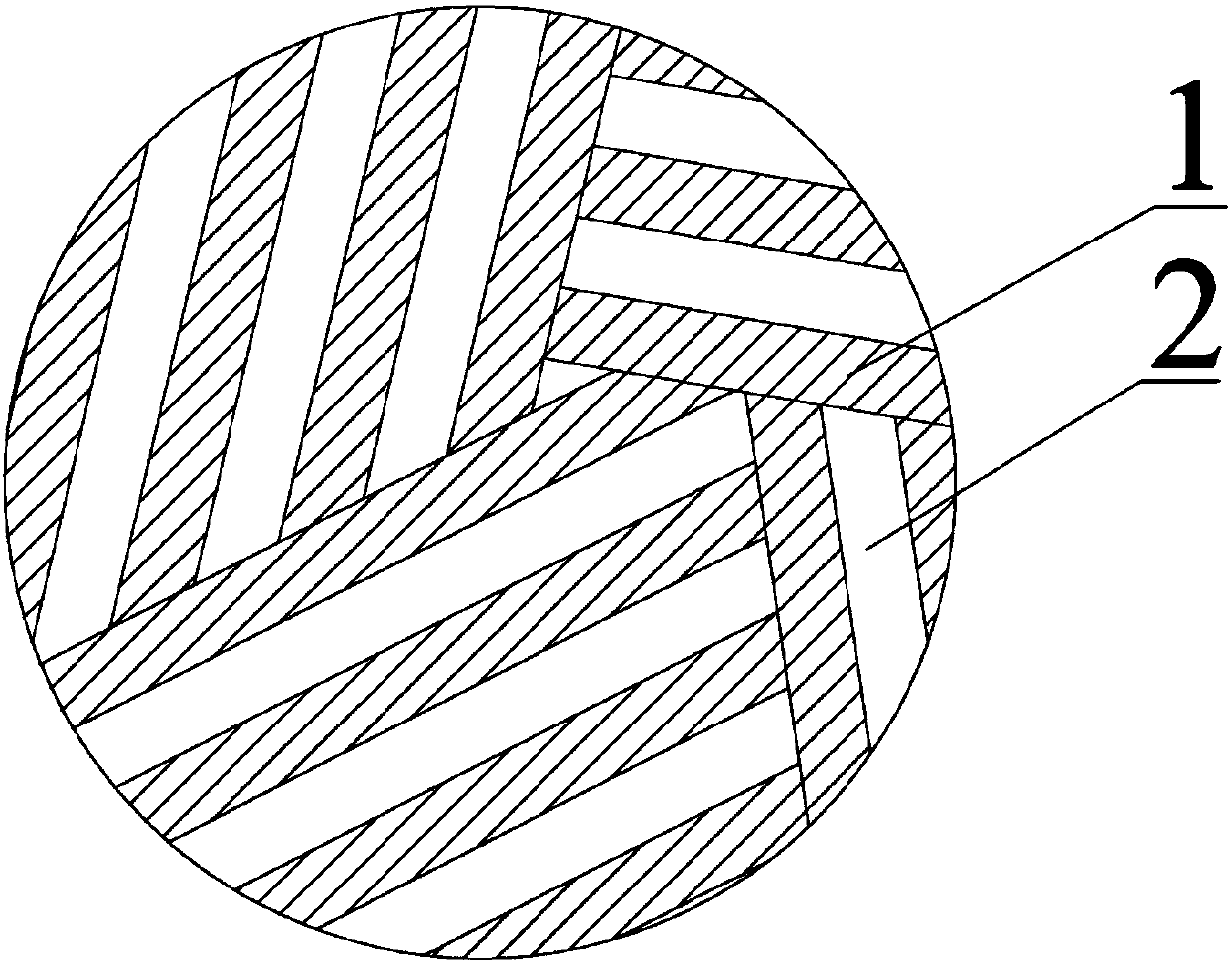

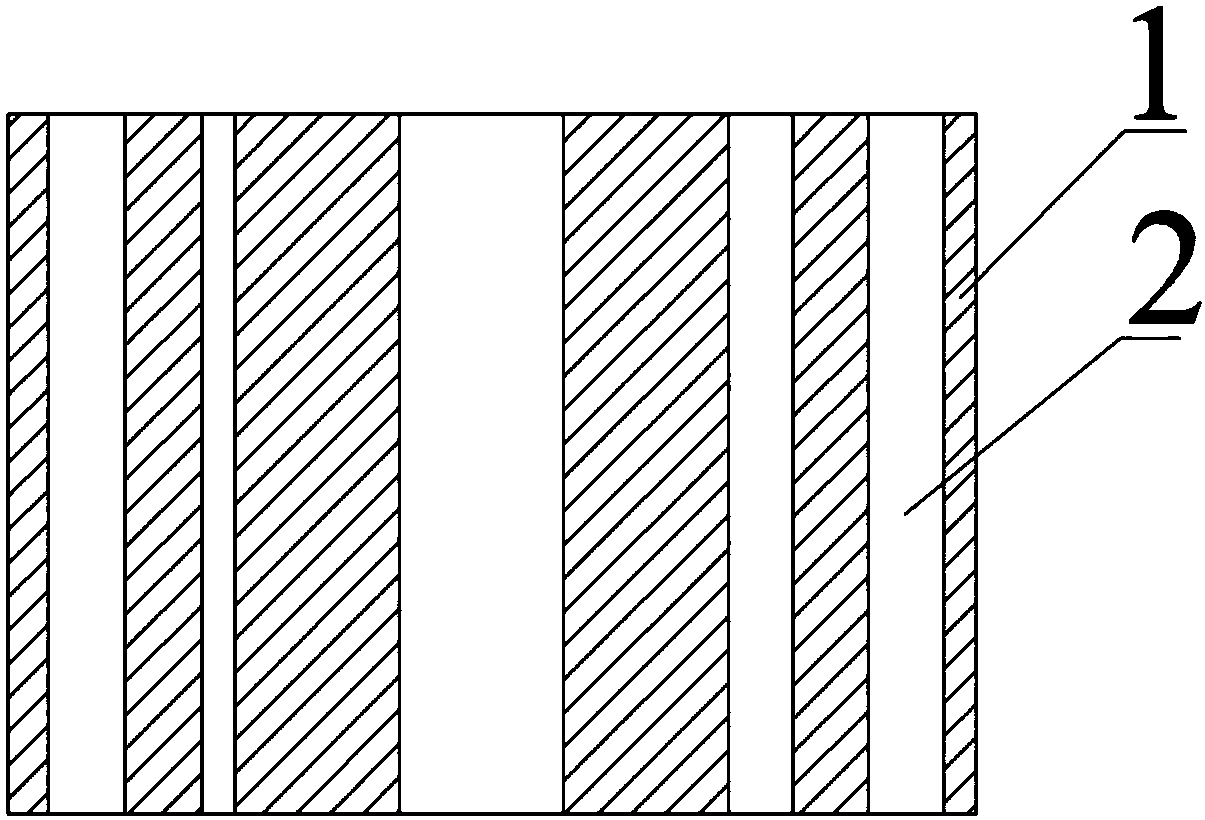

Image

Examples

preparation example Construction

[0032] A preparation method of a piezoelectric ceramic / bone cement biological piezoelectric composite material of the present invention comprises the following steps:

[0033] Step 1, prepare piezoelectric porous scaffold:

[0034] Step 1.1, weigh the following components according to volume percentage: piezoelectric ceramic powder 10%-30%, dispersant 1%-2%, binder 0.8%-1%, distilled water 67%-88.2%, the above components The sum of volume percentage is 100%;

[0035] In step 1.1, the piezoelectric ceramic powder is any one of barium titanate, calcium titanate, lithium sodium potassium niobate, potassium sodium niobate, bismuth sodium titanate, barium calcium zirconate titanate; the dispersant It is any one of sodium dodecylbenzenesulfonate, sodium polyacrylate, citric acid, polymethacrylic acid, sodium polymethacrylate; the binder is polyvinyl alcohol, polyvinylpyrrolidone, carboxymethyl One of cellulose and gum arabic;

[0036]Step 1.2, mix the components weighed in step 1...

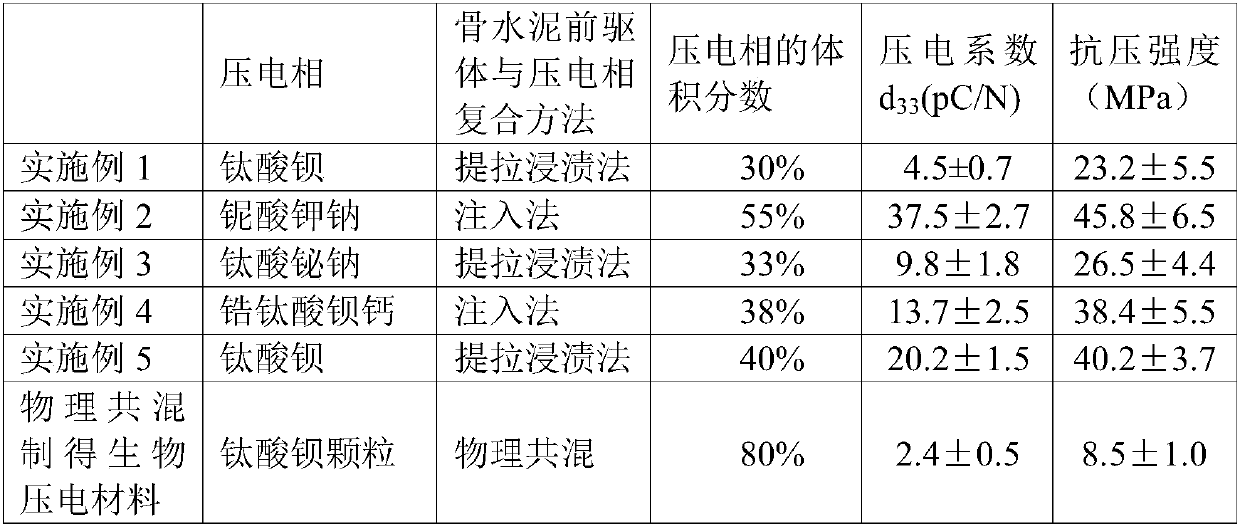

Embodiment 1

[0052] Step 1: Preparation of Piezoelectric Porous Scaffold

[0053] Take 10% of barium titanate powder, 1% of sodium dodecylbenzenesulfonate, 0.8% of polyvinyl alcohol, and 88.2% of distilled water according to the volume percentage. The volume percentage of each of the above components is 100%. After removing air bubbles in a vacuum environment, pour into a mold, freeze at -75°C for 2 hours, dry in a vacuum environment for 48 hours, and finally sinter at 1300°C for 2 hours to obtain a piezoelectric porous scaffold with a volume fraction of 30%;

[0054] Step 2: Preparation of calcium phosphate bone cement precursor

[0055] Take 30% of calcium hydrogen phosphate and 70% of tetracalcium phosphate according to the mass percentage, and the sum of the mass percentages of the above components is 100%, mix evenly to obtain the solid phase of calcium phosphate bone cement; take 64% of the solid phase of calcium phosphate bone cement according to the mass percentage , 36% phosphate...

Embodiment 2

[0061] Step 1: Preparation of Piezoelectric Porous Scaffold

[0062] Take 30% potassium sodium niobate powder, 2% citric acid, 1% polyvinylpyrrolidone, and 67% distilled water according to the volume percentage. The volume percentage of the above components is 100%. Mix the above ingredients evenly, and remove air bubbles in a vacuum environment Finally, pour it into the mold, freeze at -75°C for 2 hours, dry it in a vacuum environment for 48 hours, and finally sinter at 1300°C for 2 hours to obtain a piezoelectric porous scaffold with a volume fraction of 55%;

[0063] Step 2: Preparation of calcium phosphate bone cement precursor

[0064] Take 35% of calcium hydrogen phosphate and 65% of tetracalcium phosphate according to the mass percentage, and the sum of the mass percentages of the above components is 100%, mix evenly to obtain the solid phase of calcium phosphate bone cement; take 67% of the solid phase of calcium phosphate bone cement according to the mass percentage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com