Positive electrode material for sodium-ion battery and preparation method thereof

A sodium-ion battery and cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as low voltage and lower battery energy density, and achieve the effects of simple operation, low cost, and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

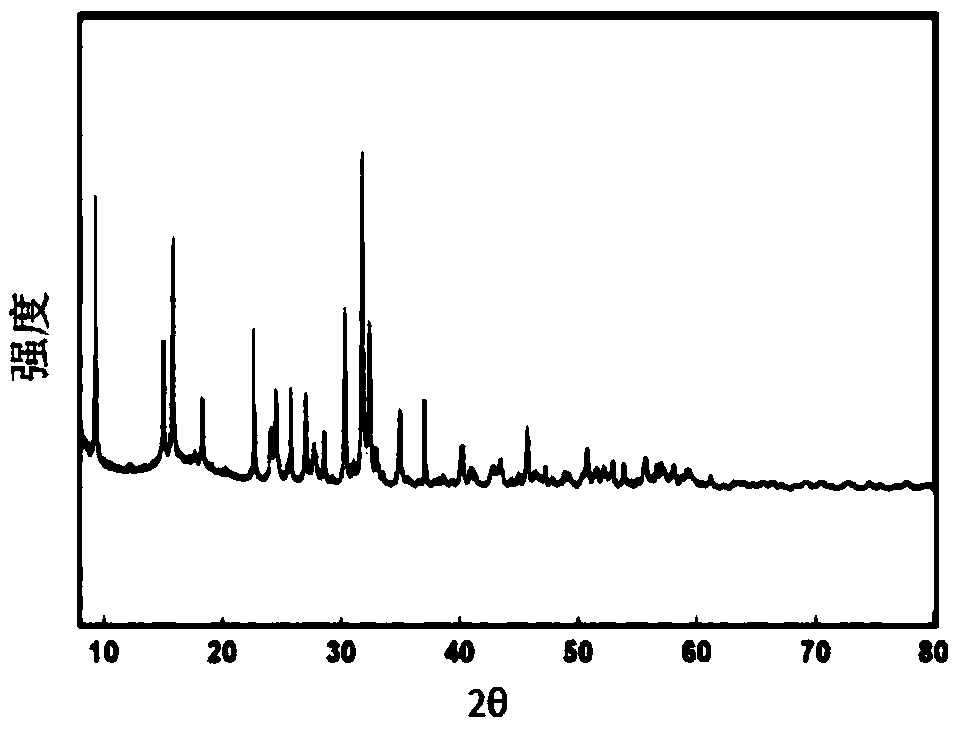

[0048] Take 0.01mol of sodium pyrophosphate, 0.02mol of ferrous oxalate, 0.01mol of manganese acetate and 0.02mol of ammonium dihydrogen phosphate in 80ml of deionized water, stir and dissolve, add 0.05mol of tetraethylene glycol, heat and stir in a water bath at 80°C until a colloid is formed, and then Dry the precursor powder in an oven at 120°C; calcinate the precursor at 550°C for 10h under an inert atmosphere to obtain the product Na 4 Fe 2 Mn(PO 4 ) 2 (P 2 o 7 ).

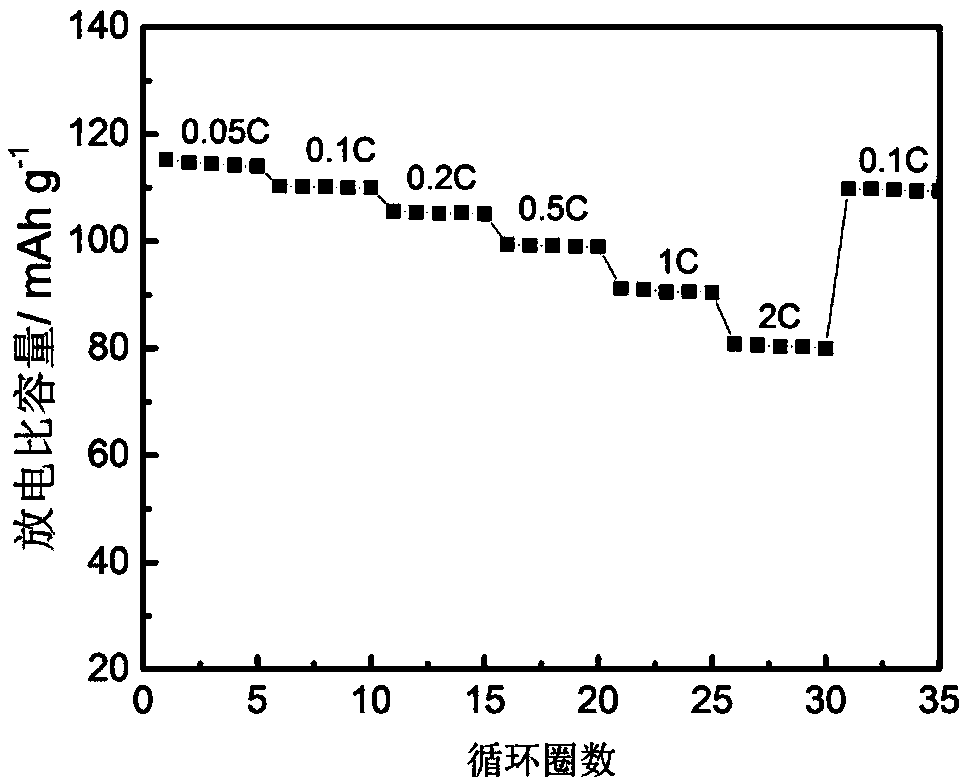

[0049] The produced Na 4 Fe 2 Mn(PO 4 ) 2 (P 2 o 7 ) Morphology (SEM) of the material see figure 1 , is a three-dimensional sheet-like porous material. The sodium ion battery composite positive electrode material prepared in this embodiment and the sodium sheet are assembled into a button battery, from image 3 It can be seen that the rate performance of the material is superior, even at a rate of 2C, it still has a capacity of 82mAh / g. From Figure 4 It can be seen from the rate cycle diagram t...

Embodiment 2

[0051] Take 0.01 mol of sodium pyrophosphate, 0.02 mol of ferrous oxalate, 0.01 mol of manganese acetate and 0.02 mol of ammonium dihydrogen phosphate in 80 ml of deionized water, stir and dissolve, add 0.08 mol of tetraethylene glycol, heat and stir in a water bath at 80°C until a colloid is formed, and then Dry the precursor powder in an oven at 120°C; calcinate the precursor at 550°C for 10h under an inert atmosphere to obtain the product Na 4 Fe 2 Mn(PO 4 ) 2 (P 2 o 7 ). The composite positive electrode material of the sodium ion battery prepared in this example and the sodium sheet were assembled into a button battery, and the specific capacity was 73.2mAh / g at a rate of 2C. The capacity retention rate was 88%.

Embodiment 3

[0053] Take 0.01mol of sodium pyrophosphate, 0.02mol of ferrous oxalate, 0.01mol of manganese acetate and 0.02mol of ammonium dihydrogen phosphate in 40ml of deionized water, stir and dissolve, add 0.05mol of tetraethylene glycol, heat and stir in a water bath at 80°C until a colloid is formed, and then Dry the precursor powder in an oven at 120°C; calcinate the precursor at 550°C for 10h under an inert atmosphere to obtain the product Na 4 Fe 2 Mn(PO 4 ) 2 (P 2 o 7 ). The composite positive electrode material of the sodium ion battery prepared in this example and the sodium sheet were assembled into a button battery, and the specific capacity was 72.8mAh / g at a rate of 2C. The capacity retention rate was 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com