Improver for soil caking

A soil compaction and improver technology, which is applied in the preparation of organic fertilizers, fertilizers made from biological waste, and applications, can solve problems such as obstacles to sustainable agricultural development, soil damage, and yield reduction, and improve soil porosity and efficiency. The effect of water storage and fertilizer retention, improvement of soil nutrient structure, and improvement of soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

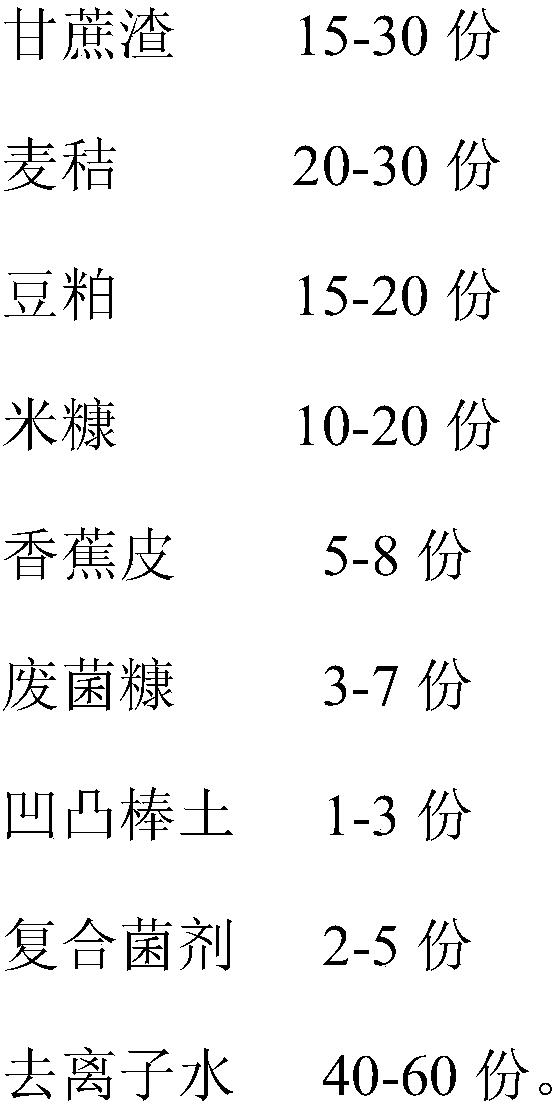

[0030] A kind of improving agent of soil compaction, comprises following raw material by weight:

[0031] The bagasse is sun-dried, crushed and passed through a 40-mesh sieve. The wheat straw is dried in the sun, cut into 4-5cm sections, sprinkled with lime powder, dried in the sun in a ventilated place, and crushed through a 20-mesh sieve. Banana peels are sun-dried and passed through a 20-mesh sieve. The spent fungus chaff was dried in the sun and passed through a 20-mesh sieve. Acid modification of attapulgite before use: attapulgite is ground through a 200-mesh sieve, 1kg is taken, mixed with 0.04kg sodium hexametaphosphate in 7L 1mol / L nitric acid solution, mixed well, ultrasonically treated at room temperature for 1h, filtered , dried at 105°C, ground through a 400-mesh sieve, and obtained. The attapulgite includes the following materials in terms of weight percentage: 50%-80% of attapulgite, 10-30% of dolomite, and the content of impurities of quartz and feldspar is ...

Embodiment 2

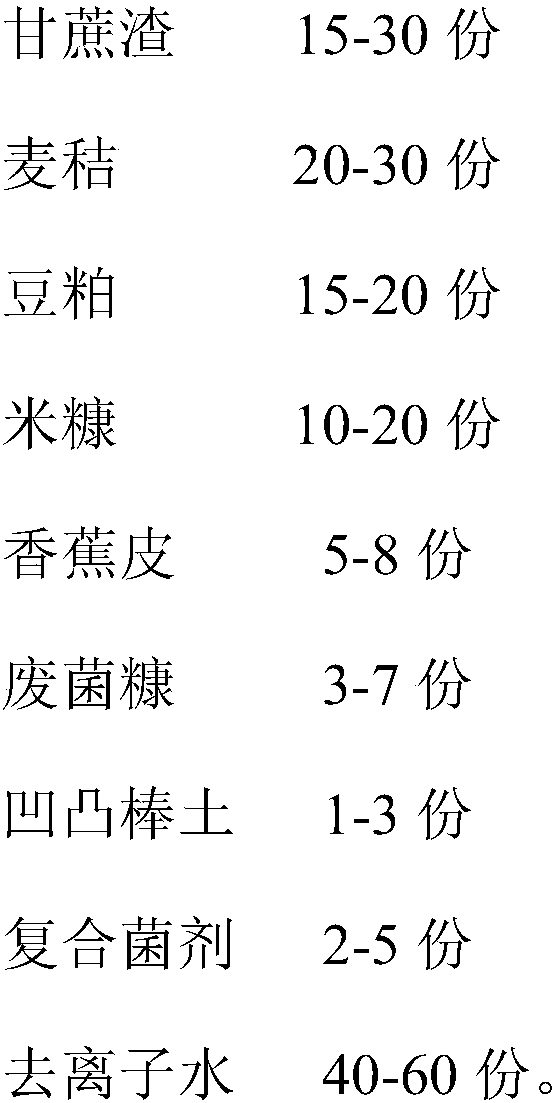

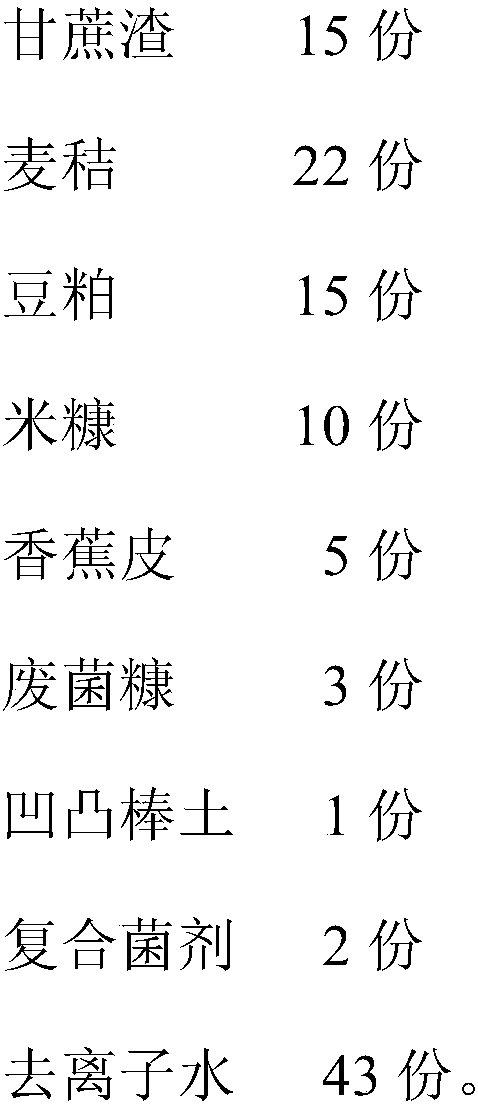

[0041] A kind of improving agent of soil compaction, comprises following raw material by weight:

[0042] The bagasse is sun-dried, crushed and passed through a 20-mesh sieve. The wheat straw is dried in the sun, cut into 4-5cm sections, sprinkled with lime powder, dried in the sun in a ventilated place, and crushed through a 20-mesh sieve. Banana peels are sun-dried and passed through a 20-mesh sieve. The spent fungus chaff was dried in the sun and passed through a 20-mesh sieve. Acid modification of attapulgite before use: attapulgite is ground through a 200-mesh sieve, 1kg is taken, mixed with 0.05kg sodium hexametaphosphate in 8L 1mol / L nitric acid solution, mixed well, ultrasonically treated at room temperature for 1h, filtered , dried at 105°C, ground through a 400-mesh sieve, and obtained. The attapulgite includes the following materials in terms of weight percentage: 50%-80% of attapulgite, 10-30% of dolomite, and the content of impurities of quartz and feldspar is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com