A kind of easy orientation, high-performance fluoro-silicon composite water-based aluminum powder paint and preparation method thereof

A high-performance, aluminum powder paint technology, applied in the direction of coating, etc., can solve the problems of poor simulation of aluminum-plastic panels, poor product storage stability, easy sinking of aluminum powder, etc., and achieve excellent rapid positioning function of aluminum powder , Eliminate the risk of coalescing and scrapping, and improve storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

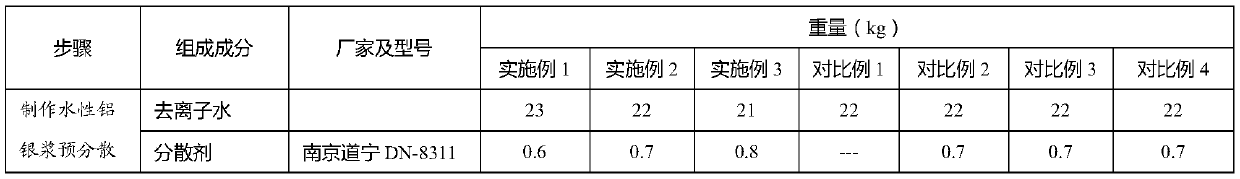

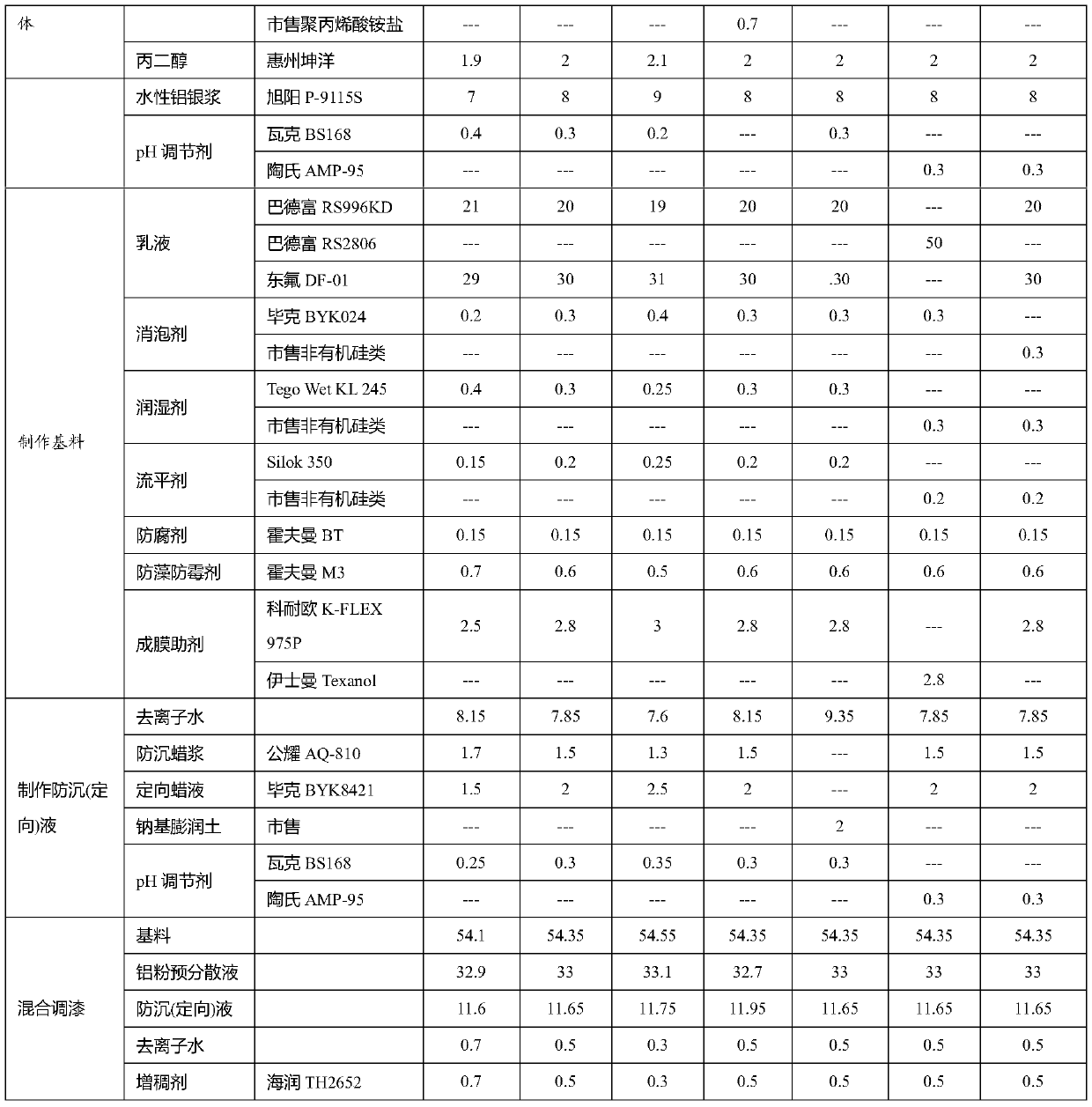

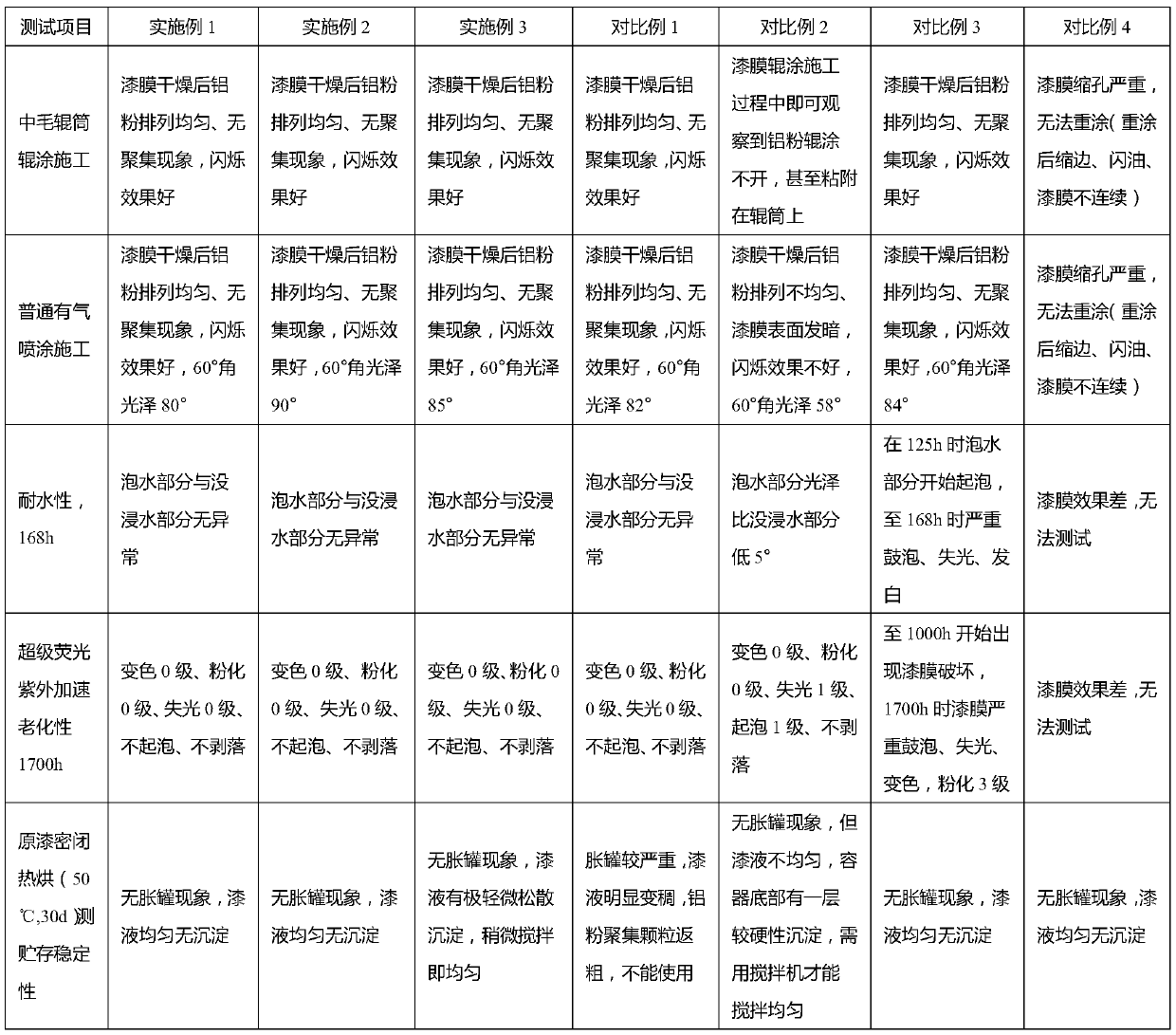

Embodiment 1

[0039] Making water-based aluminum-silver paste pre-dispersion:

[0040] Add 23kg of deionized water to the pre-dispersing tank, start stirring, and add Nanjing Daoning Chemical Co., Ltd. model DN in turn at a stirring speed of 400 rpm (it can also be a medium-speed stirring at 400-600 rpm). 0.6kg of linear block structure dispersant of -8311, 1.9kg of propylene glycol from Huizhou Kunyang Company, stir for 20min to mix evenly, and then add water-based aluminum silver model P-9115S from Anhui Xuyang Company at 400 rpm Slurry 7kg and disperse for 30min, then add 0.4kg of Wacker's BS168 silicone pH adjuster to adjust the pH to 8.5-9.5, continue stirring for 5min after adding, and then keep it closed for 24h.

[0041] In order to solve the problem of tank expansion during the storage process of composite water-based aluminum powder paint, when making the water-based aluminum-silver paste pre-dispersion, firstly mix water, linear block structure dispersant and propylene glycol eve...

Embodiment 2

[0052] Take each component according to the weight shown in Example 2 in Table 1, and repeat the method described in Example 1 to prepare fluorosilicon composite base material, water-based aluminum-silver paste pre-dispersion, anti-settling and rapid orientation liquid, according to Table 1. In the middle mixing and letdown step, the proportions of the fluorine-silicon composite base material, the water-based aluminum silver paste pre-dispersion liquid, the anti-settling and rapid orientation liquid, deionized water, and the thickener are evenly mixed to obtain a composite water-based aluminum powder paint, and then follow the steps of implementing The method of Example 1 is constructed, and the performance test results are shown in the corresponding data of Example 2 in Table 2. The pre-mixing and diluting thickener refers to diluting the thickener in the same weight of deionized water.

Embodiment 3

[0054] Take each component according to the weight shown in Example 3 in Table 1, and repeat the method described in Example 1 to prepare fluorosilicon composite base material, water-based aluminum-silver paste pre-dispersion, anti-settling and rapid orientation liquid, according to Table 1. In the middle mixing and letdown step, the proportions of the fluorine-silicon composite base material, the water-based aluminum silver paste pre-dispersion liquid, the anti-settling and rapid orientation liquid, deionized water, and the thickener are evenly mixed to obtain a composite water-based aluminum powder paint, and then follow the steps of implementing The method of Example 1 was constructed. The performance test results are shown in the corresponding data of Example 3 in Table 2. The pre-mixing and diluting thickener refers to diluting the thickener in the same weight of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com