Metal powder coating capable of enhancing decorative effect and preparation method thereof

A metal powder and decorative effect technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of difficult coating defects, uneven powder coating on corners, high curing conditions, etc., and achieve low construction costs and high decorative effects Good, the effect of improving low temperature toughness and heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

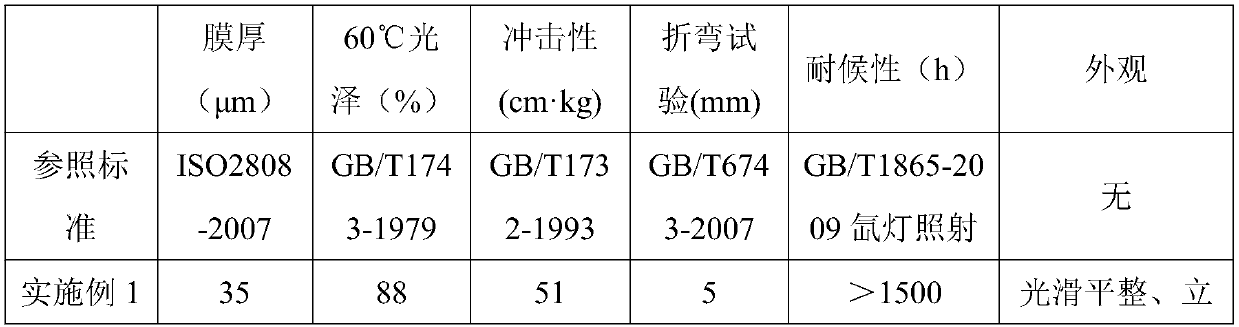

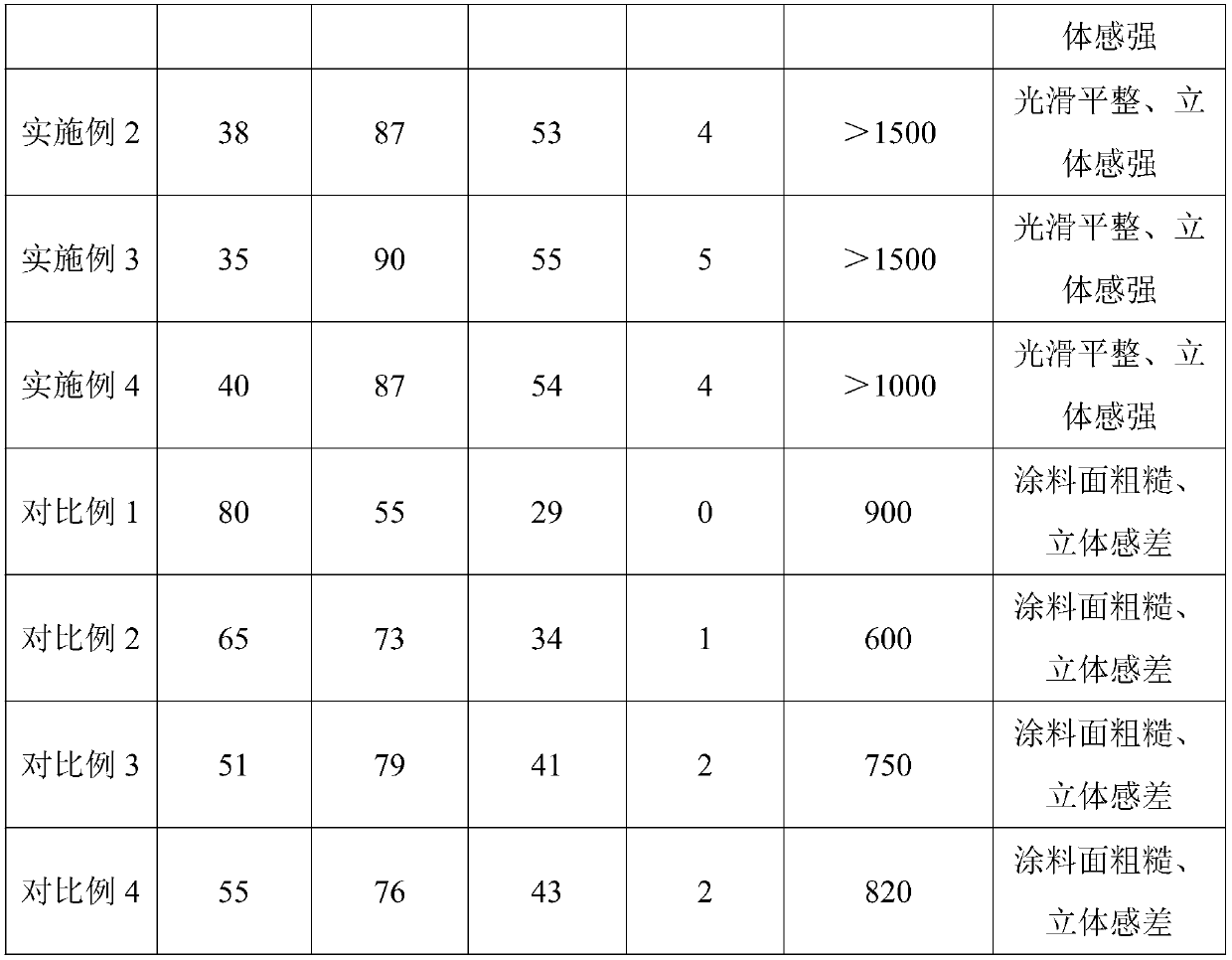

Examples

Embodiment 1

[0023] The metal powder coating for enhancing the decorative effect is characterized in that: in parts by weight, it includes the following raw materials: 15 parts of modified polyester compound, 1 part of bentonite, 0.5 part of power enhancer, 1.5 parts of metallic pigment, and 0.5 part of degassing agent , 0.2 part of dispersant, 0.5 part of toughening agent, 0.2 part of brightening agent, 0.1 part of wetting agent, 0.1 part of preservative, 0.1 part of antioxidant, 0.2 part of light stabilizer, and the charge enhancer is β-hydroxyalkane base amide, the degassing agent is stearic acid, the dispersant is sulfur zinc, the toughening agent is pvc toughening agent, the wetting agent is heptadecyl imidazoline, and the preservative is 5-chloro-2- Methyl-4-isothiazolin-3-one, the antioxidant is a phosphite, and the light stabilizer is a hindered amine light stabilizer.

[0024] The modified polyester compound, in parts by weight, includes the following raw materials: 10.5 parts of ...

Embodiment 2

[0032] The metal powder coating for enhancing the decorative effect is characterized in that: in parts by weight, it includes the following raw materials: 20 parts of modified polyester compound, 3 parts of bentonite, 1 part of power enhancer, 4.5 parts of metallic pigment, and 1 part of degassing agent , 0.5 part of dispersant, 1 part of toughening agent, 0.5 part of brightening agent, 0.5 part of wetting agent, 0.3 part of preservative, 0.3 part of antioxidant, 0.5 part of light stabilizer, and the charge enhancer is β-hydroxyalkane base amide, the degassing agent is stearic acid, the dispersant is sulfur zinc, the toughening agent is pvc toughening agent, the wetting agent is heptadecyl imidazoline, and the preservative is 5-chloro-2- Methyl-4-isothiazolin-3-one, the antioxidant is a phosphite, and the light stabilizer is a hindered amine light stabilizer.

[0033] The modified polyester compound, in parts by weight, includes the following raw materials: 13 parts of polyeth...

Embodiment 3

[0041] The metal powder coating for enhancing the decorative effect is characterized in that: in parts by weight, it includes the following raw materials: 18 parts of modified polyester compound, 2 parts of bentonite, 0.8 part of power enhancer, 3 parts of metallic pigment, and 0.8 part of degassing agent , 0.4 part of dispersant, 0.7 part of toughening agent, 0.4 part of brightening agent, 0.3 part of wetting agent, 0.2 part of preservative, 0.14 part of antioxidant, 0.4 part of light stabilizer, and the described charging agent is β-hydroxyalkane base amide, the degassing agent is stearic acid, the dispersant is sulfur zinc, the toughening agent is pvc toughening agent, the wetting agent is heptadecyl imidazoline, and the preservative is 5-chloro-2- Methyl-4-isothiazolin-3-one, the antioxidant is a phosphite, and the light stabilizer is a hindered amine light stabilizer.

[0042] The modified polyester compound, in parts by weight, includes the following raw materials: 12 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com