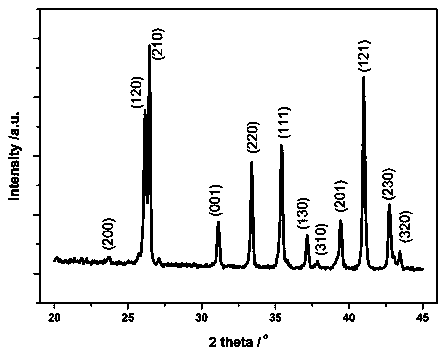

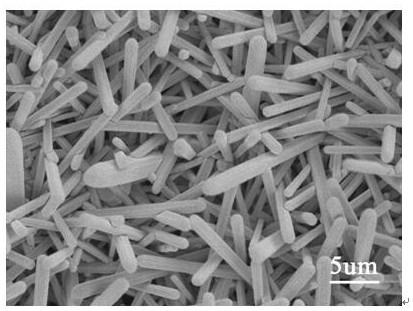

A kind of preparation method of mullite whisker ceramic material with high aspect ratio

A technology for mullite whiskers and ceramic materials, which is applied in the field of preparation of mullite whisker ceramic materials with high aspect ratio, can solve the problem that it is difficult to obtain equal mullite with high aspect ratio, and achieve dimensional stability, Effects of improved mechanical properties and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is a method for synthesizing ceramic materials with high aspect ratio mullite whiskers as the main crystal phase, and the steps are as follows:

[0026] (1) The mullite ceramic material contains the following components by weight: quartz glass powder 22%, Al 2 o 3 75%, Y 2 o 3 1.0%, metal tungsten powder 1.0%, amorphous silicon powder 1.0%, impurity K 2 O and Na 2 The sum of O contents is less than 0.5%.

[0027] (2) Quartz glass powder in the above raw materials requires SiO 2 Content greater than 98%, Al 2 o 3 Purity greater than 97%, Y 2 o 3 The purity of metal tungsten powder is greater than 99%, the Si content in amorphous silicon is not less than 98%, and all raw materials pass through a 200-mesh standard sieve.

[0028] (3) Preliminary ball milling is carried out with zirconia ball mills after weighing and mixing evenly according to the proportion. The mass ratio of the ball mills to the mixture is 2:1, the ball milling speed is 400 r / m...

Embodiment 2

[0035] This embodiment is a method for synthesizing ceramic materials with high aspect ratio mullite whiskers as the main crystal phase, and the steps are as follows:

[0036] (1) The mullite ceramic material contains the following components by weight: 25% of quartz glass powder, Al 2 o 3 73%, Y 2 o 3 0.7%, metal tungsten powder 0.5%, amorphous silicon powder 0.8%. K in impurities 2 O and Na 2 The sum of O contents is less than 0.5%.

[0037] (2) Quartz glass powder in the above raw materials requires SiO 2 Content greater than 98%, Al 2 o 3 Purity greater than 97%, Y 2 o 3 The purity of metal tungsten powder is greater than 99%, the Si content in amorphous silicon is not less than 98%, and all raw materials pass through a 200-mesh standard sieve.

[0038] (3) Preliminary ball milling is carried out with zirconia ball mills after being weighed and mixed evenly according to the proportion. The mass ratio of the ball mills to the mixture is 4:1, the ball milling speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com