Preparation method of MoS2 ceramic target

A ceramic target material, the technology of step 2 is applied in the metal material coating process, ion implantation plating, coating and other directions, which can solve the problem of difficulty in obtaining a ceramic target material with uniform composition, large differences in melting point and density, and low target material purity. and other problems, to achieve the effect of being conducive to industrialized large-scale production, fine and uniform grain size, and stable target performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

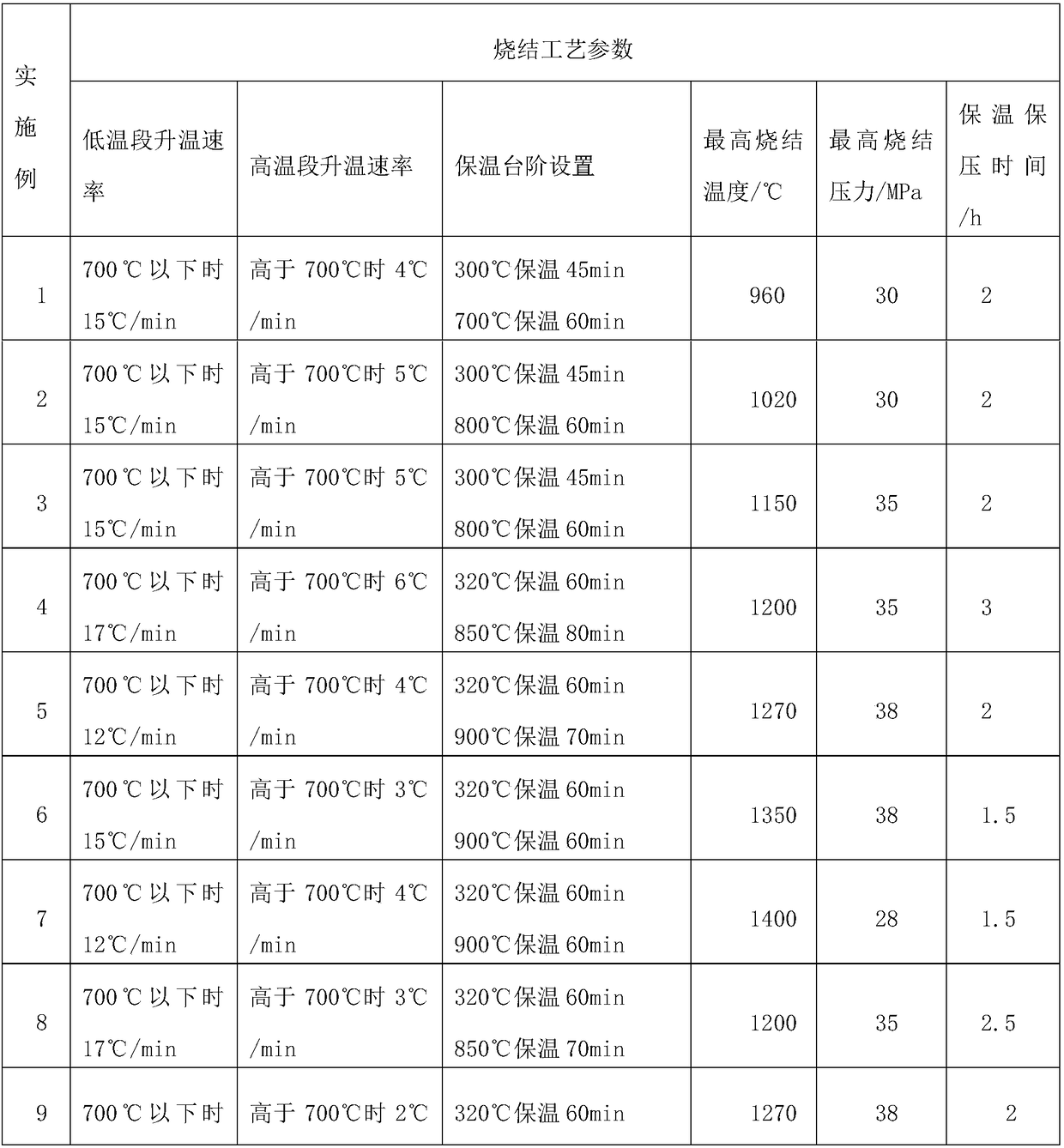

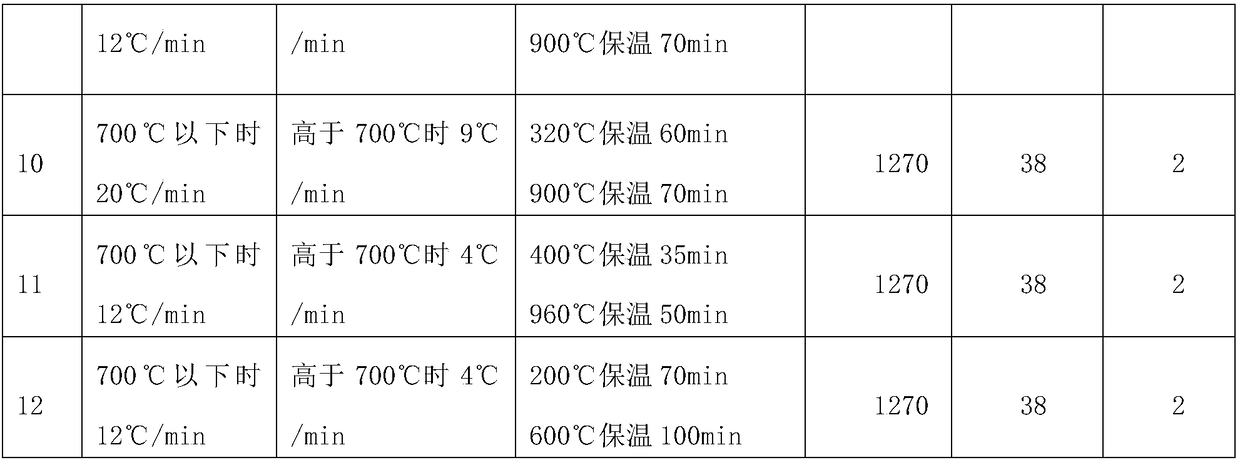

[0033] Table 1 has listed the hot-pressing sintering process parameter of embodiment 1-12, and concrete preparation steps are as follows:

[0034] (1) Powder pretreatment: use the above MoS 2 Raw material powder, the average Fischer particle size of the powder is 0.65 μm, and it is kept in a vacuum drying oven at 120°C for 3 hours; the dried powder is passed through a 150-mesh vibrating sieve to remove agglomerates and agglomerated phases, and the loose, evenly distributed powder under the sieve is taken spare;

[0035] (2) mold loading, the under-sieve powder that step (1) is obtained is evenly packed in the isostatic graphite mould;

[0036] (3) Hot-press sintering. After the mold loading is completed, place the mold in a hot-press furnace, add an initial pressure of 12MPa, evacuate to below 5Pa, heat up to the highest sintering temperature according to the method described in Table 1, and linearly increase the pressure, and heat Press sintering, the specific sintering par...

Embodiment 13-16

[0048] In Examples 13-16, except that the particle size of the powder is different from that of Example 5, other process parameters are the same as those of Example 5, specifically MoS 2 The particle size of the raw material powder and the properties of the target material are shown in Table 3.

[0049] The performance of the target material prepared by the embodiment 13-16 of table 3

[0050]

Embodiment 17

[0052] The target material of this embodiment is prepared by the following method:

[0053] (1) Powder pretreatment: use the above MoS 2 Raw material powder, the average Fischer particle size of the powder is 0.65 μm, and it is kept in a vacuum drying oven at 120°C for 3 hours; the dried powder is passed through a 150-mesh vibrating sieve to remove agglomerates and agglomerated phases, and the loose, evenly distributed powder under the sieve is taken spare;

[0054] (2) mold loading, the under-sieve powder that step (1) is obtained is evenly packed in the isostatic graphite mould;

[0055] (3) Hot pressing sintering. After the mold loading is completed, place the mold in a hot pressing furnace, add an initial pressure of 12MPa, evacuate to below 5Pa, and then raise the temperature to the highest sintering temperature of 1270℃ at a heating rate of 9℃ / min in one step, and directly Quickly increase the pressure to 38MPa, keep the pressure for 2 hours;

[0056] (4) Demoulding. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com