Near-zero-emission and CO2 recycling type fossil energy utilization method

A fossil energy, near-zero emission technology, applied in gasification process, petroleum industry, granular/powder fuel gasification, etc. and water consumption, improving energy efficiency and reducing combustion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

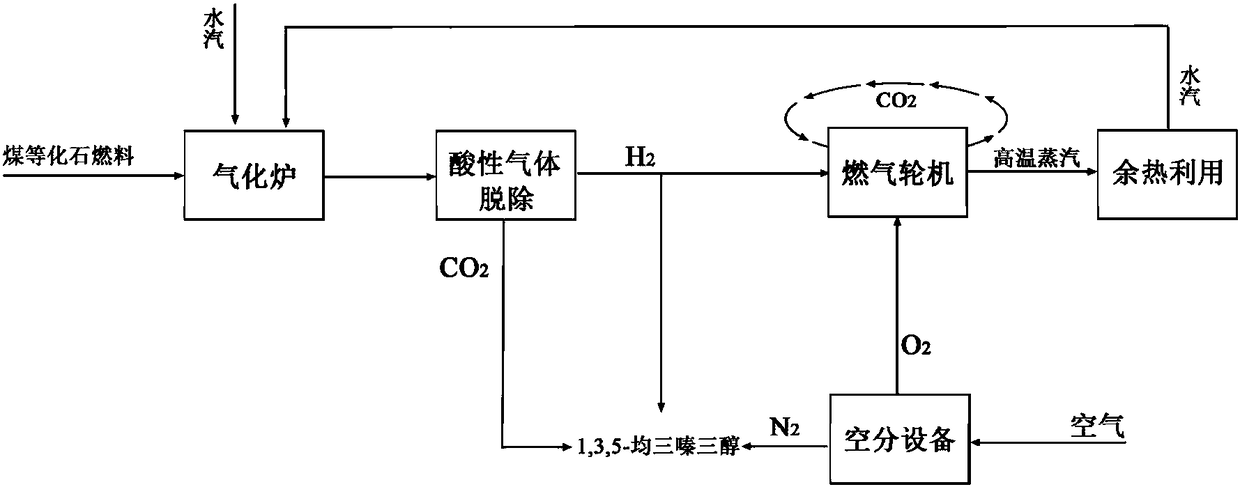

[0028] A near-zero emission, CO 2 Fossil energy utilization methods for resource utilization, CO produced in the process 2 Synthetic chemicals, a certain amount of CO 2 Return to the power generation system for ring use, no CO in the whole process 2 External discharge; including the following steps:

[0029] (1) 1000 tons of lignite (sulfur content 2.03%) is used as fluidization gas with water vapor, and the gasification reaction is carried out at a pressure of 9.3Mpa and a temperature of 1350°C to obtain crude reformed gas, which is at a pressure of 6.5Mpa Under the condition of temperature and 230 ℃, the shift reaction is carried out to obtain the crude shift gas;

[0030] (2) After the crude shift gas goes through the low-temperature methanol washing process, first about 165 tons of high-purity hydrogen with a concentration of 99.5% are obtained, and then about 1076 tons of high-purity CO with a concentration of 99.1% are obtained by decompression analysis 2 ;

[0031]...

Embodiment 2

[0035] A near-zero emission, CO 2 Fossil energy utilization methods for resource utilization, synthetic chemicals, a certain amount of CO 2 Input back to the power generation system, no CO in the whole process 2 External discharge; including the following steps:

[0036] (1) 1500 tons of lignite (sulfur content 2.10%) use water vapor as fluidization gas, carry out gasification reaction under the conditions of pressure of 8.5Mpa and temperature of 1330°C, obtain crude reformed gas, crude reformed gas at the pressure of 6.5Mpa Under the condition of temperature and 240 ℃, carry out the shift reaction to obtain the crude shift gas;

[0037] (2) After the crude shift gas goes through the low-temperature methanol washing process, about 248 tons of high-purity hydrogen with a concentration of 99.4% are first obtained, and then about 1,600 tons of high-purity CO with a concentration of 99.1% are obtained by decompression analysis 2 ;

[0038] (3) High-purity CO 2 and high-purity...

experiment example

[0050] Taking Dazhuang coal as an example, Dazhuang coal is one of the common types of coal with high carbon content and low hydrogen content. The elemental analysis of Dazhuang coal is as follows:

[0051] Table 1

[0052]

[0053] The method of embodiment 1-2 and comparative example 1-2: the impact of different gas distribution on product yield and power generation is shown in Table 2:

[0054] Table 2

[0055]

[0056] From the comparison in Table 2, it can be directly seen that the distribution of different proportions of gas directly leads to the reduction of the yield and power generation of 1,3,5-s-triazinetriol, and the gas distribution in the coupling process is unreasonable CO 2 recycling and underutilization of C atoms, CO 2 It will be emitted into the environment during the coupling process, resulting in the loss of C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com