Preparation method of single-layer flaky lithium-rich manganese-based positive electrode material of graphene template

A lithium-rich manganese-based, positive electrode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as poor cycle stability and rate performance, damage to the surface lattice structure of materials, and low initial Coulombic efficiency , achieving good rate performance, maintaining stability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

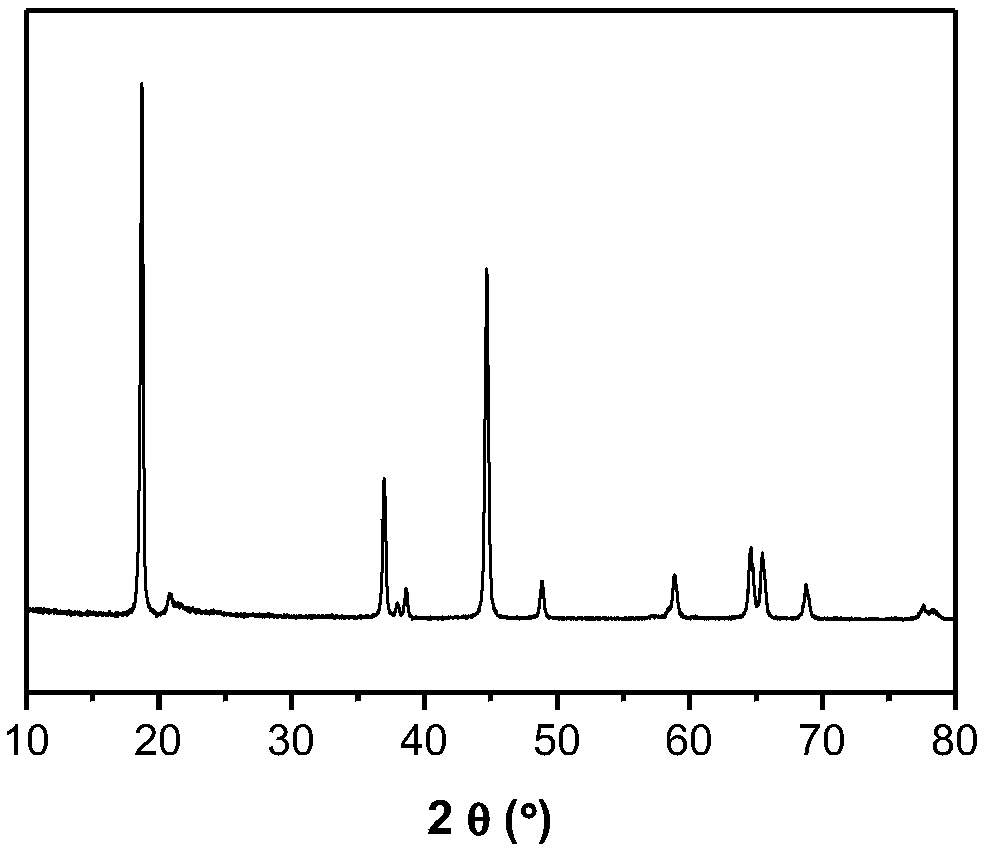

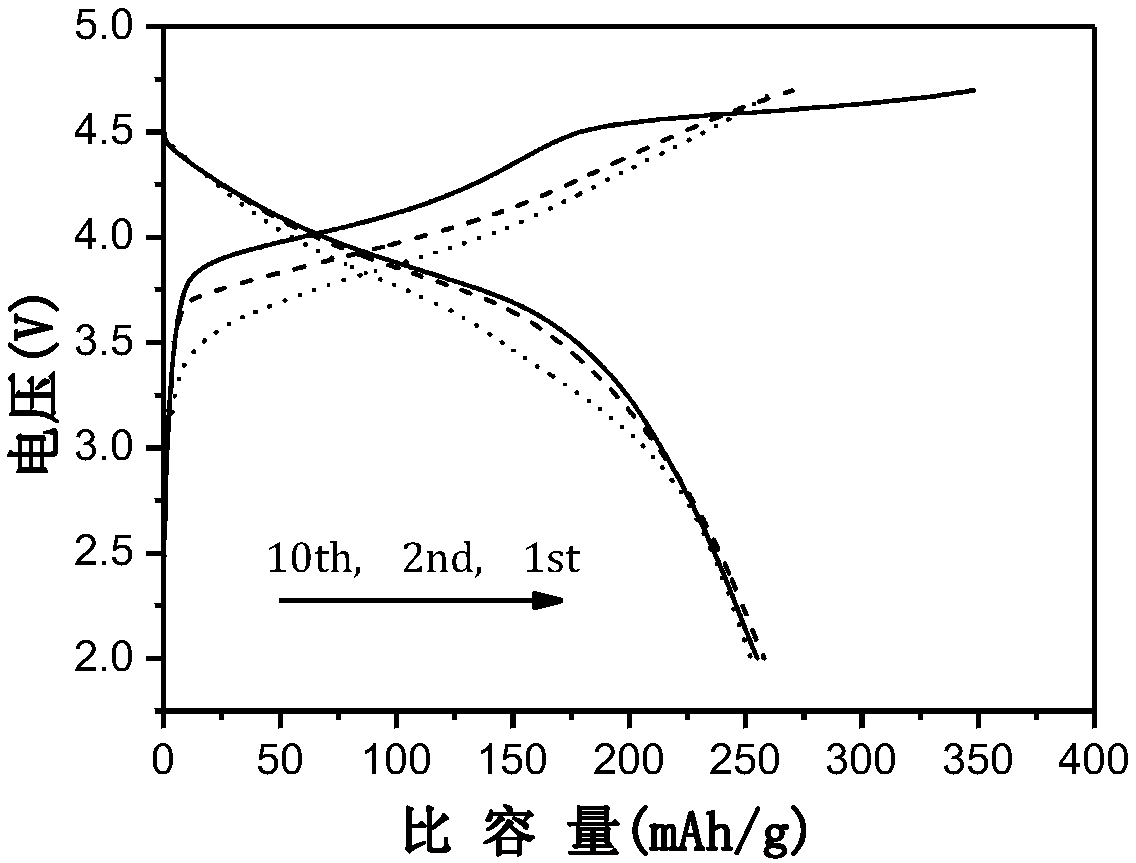

[0028] The preparation formula is 0.5Li 2 MnO 3· 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Graphene-templated single-layer flake lithium-rich manganese-based cathode materials

[0029] (1) Weigh 15.30g of lithium acetate dihydrate, 16.30g of manganese acetate tetrahydrate, 4.11g of cobalt acetate tetrahydrate, and 4.11g of nickel acetate tetrahydrate and mix them, add 200ml of deionized water, stir well to dissolve, and make mixed salt solution;

[0030] (2) Dissolve 5mg of graphene in 100ml of deionized water, ultrasonically disperse it evenly, add 10.5g of citric acid monohydrate, and continue ultrasonically to dissolve;

[0031] (3) Slowly add the mixed salt solution in step (1) dropwise to the solution in step (2) and stir thoroughly, and add ammonia water to adjust the pH value of the material to 8 to obtain a sol;

[0032] (4) Put the sol in a water bath, heat and stir at 100°C until the solution becomes gelatinous;

[0033] (5) Put the gel into a freeze dryer for freeze-dry...

Embodiment 2

[0038] The preparation formula is 0.5Li 2 MnO 3· 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Graphene-templated single-layer flake lithium-rich manganese-based cathode materials

[0039] (1) Weigh 15.30g of lithium acetate dihydrate, 16.30g of manganese acetate tetrahydrate, 4.11g of cobalt acetate tetrahydrate, and 4.11g of nickel acetate tetrahydrate, and mix them, add 100ml of deionized water, stir well to dissolve, and make mixed salt solution;

[0040] (2) Dissolve 10mg of expanded graphite in 100ml of deionized water, disperse it evenly with ultrasound, add 9g of glucose, and continue to dissolve it with ultrasound;

[0041] (3) Slowly add the mixed salt solution of step (1) dropwise into the solution of step (2), stir well, and add ammonia water to adjust the pH value of the material to 7 to obtain a sol;

[0042] (4) Put the sol in a water bath, heat and stir at 100°C until the solution becomes gelatinous;

[0043] (5) Put the gel into a freeze dryer for freeze-drying until ...

Embodiment 3

[0047] The preparation formula is 0.5Li 2 MnO 3· 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Graphene-templated single-layer flake lithium-rich manganese-based cathode materials

[0048] (1) Weigh 15.30g of lithium acetate dihydrate, 16.30g of manganese acetate tetrahydrate, 4.11g of cobalt acetate tetrahydrate, and 4.11g of nickel acetate tetrahydrate, and mix them, add 100ml of deionized water, stir well to dissolve, and make mixed salt solution;

[0049] (2) Dissolve 5mg of graphene in 100ml of deionized water, ultrasonically disperse it evenly, add 10.5g of citric acid monohydrate, and continue ultrasonically to dissolve;

[0050] (3) Slowly add the mixed salt solution in step (1) dropwise to the solution prepared in step (2), stir well, add ammonia water to adjust the pH value of the material to 8.5, and obtain a sol;

[0051] (4) Put the sol in a water bath, heat and stir at 110°C until the solution becomes gel;

[0052] (5) Put the gel into a freeze dryer for freeze-drying un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com