A kind of gel material and preparation method thereof

A gel material and raw material technology, applied in the field of gel material and its preparation, can solve the problems of poor impact resistance, poor mechanical properties, low temperature resistance, etc., achieve excellent impact hardening performance, and the preparation method is simple and easy to expand The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

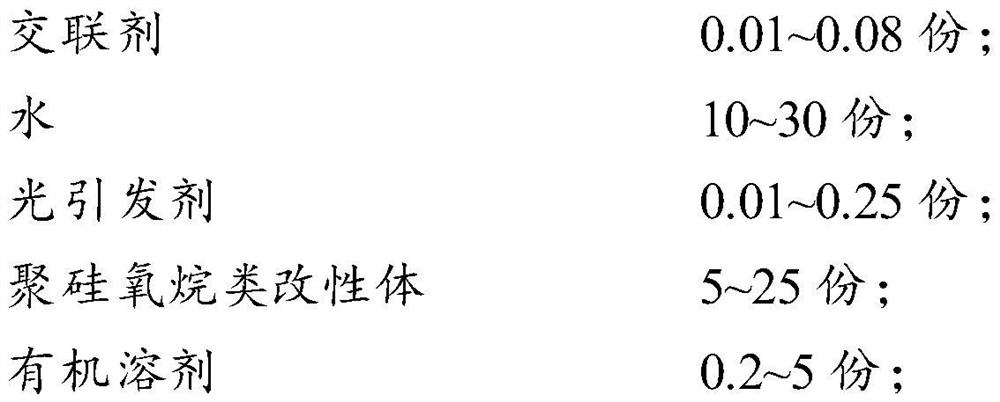

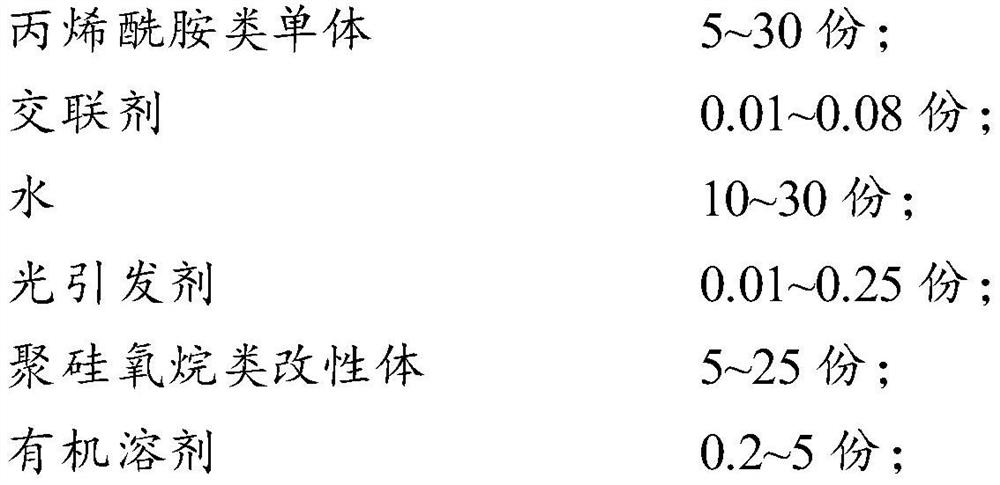

[0089] The present invention also provides a preparation method of the gel material described in the above technical solution, comprising the following steps:

[0090] a) mixing the polysiloxane modified body with an organic solvent to obtain a modified body solution;

[0091] mixing acrylamide monomers, a crosslinking agent and water to obtain a monomer solution;

[0092] b) Mixing the modifier solution, the monomer solution and the photoinitiator, and irradiating with ultraviolet light to form a gel material.

[0093] Wherein, the type, dosage and source of the polysiloxane modified body, organic solvent, acrylamide monomer, crosslinking agent, water and photoinitiator are all consistent with those described in the above technical scheme. This will not repeat them one by one.

[0094] In the step a), the mixing method of the polysiloxane modified body and the organic solvent is preferably ultrasonic dispersion. The mixing temperature of the polysiloxane-based modified bod...

Embodiment 1

[0100] 1.1 Sample preparation

[0101] After mixing 20 parts by mass of diamino-terminated polydimethylsiloxane (molecular weight: 20,000, viscosity: 800cst) and 1.5 parts of trimethoxyboroxane evenly, stir and react at 120°C for 4 hours to obtain a prepolymer solution ; Then add 0.4 parts of isophorone diisocyanate, stir and react at 90°C for 4 hours to obtain a reaction product. After the product was dried at 120°C for 36 hours, it was extruded through a twin-screw extruder at 100°C to obtain a polysiloxane modified body.

[0102] Add 10 g of modified polysiloxane into 1 g of ethanol, ultrasonically disperse at 25° C. for 0.5 h, and place at room temperature for 2 h to obtain a modified solution. 10g of N,N-dimethylacrylamide, 0.01g of aziridine and 20g of water were uniformly mixed at 30°C, and then cooled to room temperature to obtain a monomer solution. After mixing the obtained modified body solution, monomer solution and 0.01g 1-hydroxy-cyclohexyl-phenyl ketone evenly...

Embodiment 2

[0107] 20 parts by mass of vinyl-terminated hydroxyl-terminated polydimethylsiloxane (dihydroxy-terminated polydimethylsiloxane with vinyl side groups, molecular weight 3000, viscosity 80cst) and 1.5 parts of trimethoxyboroxine After the hexacyclic rings are evenly mixed, stir and react at 120°C for 4 hours to obtain a prepolymer solution; then add 0.4 parts of isophorone diisocyanate, stir and react at 90°C for 4 hours to obtain a reaction product. After the product was dried at 120°C for 36 hours, it was extruded through a twin-screw extruder at 100°C to obtain a polysiloxane modified body.

[0108] Add 8 g of modified polysiloxane into 1 g of tetrahydrofuran, ultrasonically disperse at 35° C. for 1 hour, and then place at room temperature for 3 hours to obtain a modified solution. 12g of N-isopropylacrylamide, 0.05g of citric acid and 20g of water were uniformly mixed at 35°C, and then cooled to room temperature to obtain a monomer solution. After mixing the obtained modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com