Method for preparing nonenzymatic biosensor based on microelectrode array

A technology of microelectrode array and biosensor, which is applied in the field of photolithography and electrochemical sensors, can solve the problems of uncontrollable porous structure and composite microstructure, unfavorable large-scale promotion, large batch-to-batch difference, etc., and achieve excellent stability Performance and detection performance, avoiding radiation hazards, and increasing the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

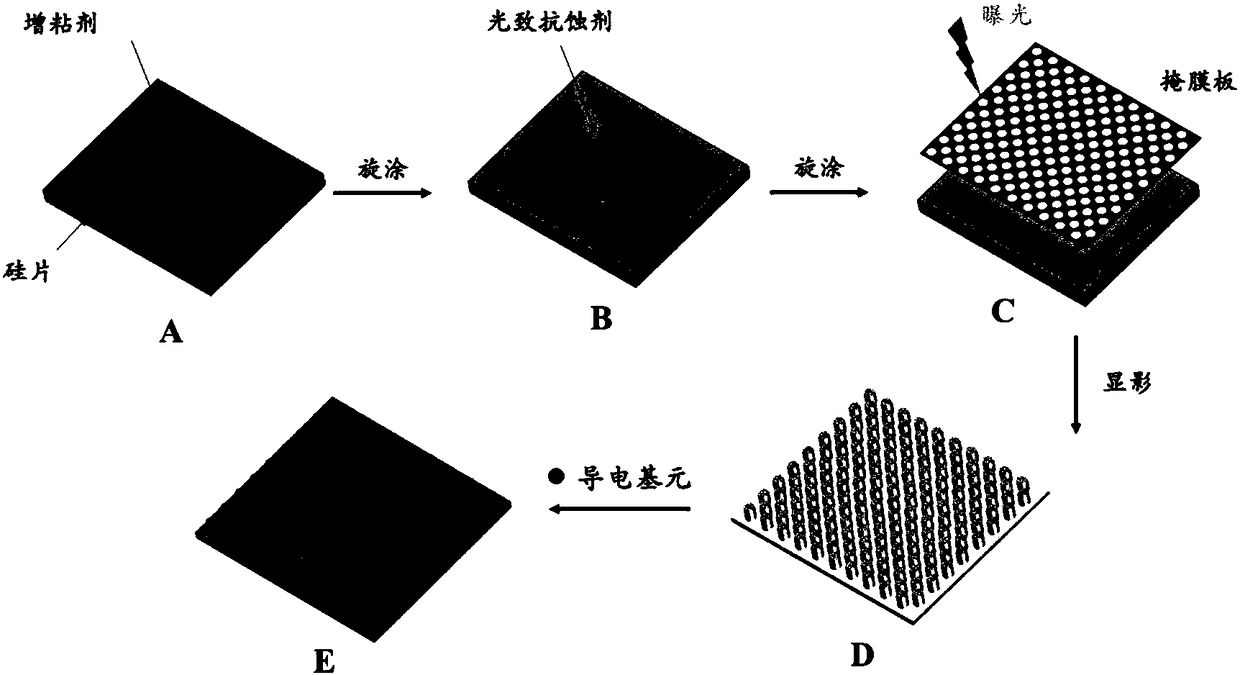

[0044] (1) Fabrication of photolithographic microelectrode arrays

[0045]Spin-coat a layer of adhesion promoter (OMNICOAT) on the silicon wafer after pretreatment, and apply negative photoresist SU-82025 on it after drying, and perform pre-baking, exposure, post-baking, development, and hardening processes to complete the process. The process of transferring the pattern on the mask plate to the surface of the substrate to obtain the required array pattern. The lithography process is:

[0046] Coating film: spin coating method, forward rotation at 600r / min for 10s, back rotation at 2600r / min for 40s, wet film thickness is 50μm;

[0047] Pre-baking: keep in an oven at 65°C for 1min, heat up to 95°C for 6min, then cool down to 65°C for 1min, and let stand for 15min;

[0048] Exposure: Use a mask with a hole diameter and spacing of 50 μm, an exposure wavelength of 365 nm, and a light intensity of 12.9 mw / cm 2 , the time is 9s;

[0049] Post-baking: Keep in an oven at 65°C for...

Embodiment 2

[0057] (1) Fabrication of photolithographic microelectrode arrays

[0058] Spin-coat a layer of adhesion promoter (OMNICOAT) on the silicon wafer after pretreatment, and apply negative photoresist SU-82025 on it after drying, and perform pre-baking, exposure, post-baking, development, and hardening processes to complete the process. The process of transferring the pattern on the mask plate to the surface of the substrate to obtain the required array pattern. The lithography process is:

[0059] Coating film: spin coating method, forward rotation at 600r / min for 10s, back rotation at 4350r / min for 40s, wet film thickness is 20μm;

[0060] Pre-baking: place the photoresist film in an oven at 65°C for 1 minute, raise the temperature to 95°C for 5 minutes, then cool down to 65°C for 1 minute, and let it stand for 15 minutes;

[0061] Exposure: Use a mask with a hole diameter and spacing of 10 μm, an exposure wavelength of 365 nm, and a light intensity of 12.9 mw / cm 2 , the time...

Embodiment 3

[0070] (1) Fabrication of photolithographic microelectrode arrays

[0071] Spin-coat a layer of adhesion promoter (OMNICOAT) on the silicon wafer after pretreatment, and apply negative photoresist SU-82050 on it after drying, and perform pre-baking, exposure, post-baking, development, and hardening processes to complete The process of transferring the pattern on the mask plate to the surface of the substrate to obtain the required array pattern. The lithography process is:

[0072] Coating film: spin coating method, forward rotation at 600r / min for 10s, back rotation at 1000r / min for 40s, wet film thickness is 100μm;

[0073] Pre-baking: place the photoresist film in an oven at 65°C for 5 minutes, raise the temperature to 95°C for 10 minutes, then cool down to 65°C for 1 minute, and let stand for 15 minutes;

[0074] Exposure: Use a mask with a hole diameter and spacing of 5 μm, an exposure wavelength of 365 nm, and a light intensity of 12.9 mw / cm 2 , the time is 11s;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com