Preparation method of industrial high-grade pure potassium nitrate

A preparation process, the technology of potassium nitrate, applied in the field of preparation of industrialized superior pure potassium nitrate, can solve the problems that cannot be directly applied to industrialized production, the process steps are complicated, and the production efficiency is low, so as to shorten the preparation cost and cycle, and optimize the purification Efficiency, the effect of large product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

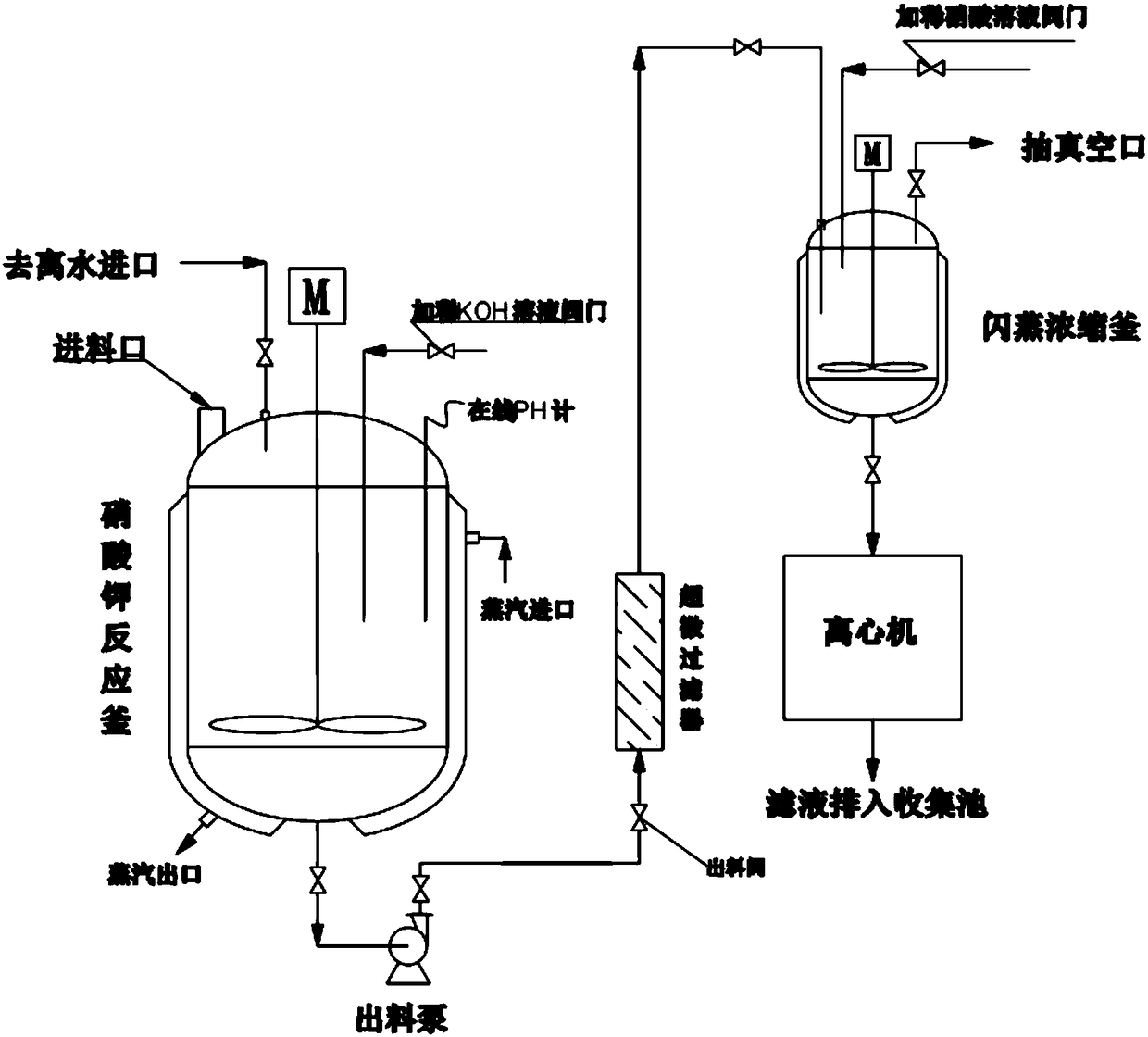

[0019] Embodiment 1, a kind of preparation technology of industrialized superior grade pure potassium nitrate, the steps are as follows:

[0020] (1) Preparation of purified potassium nitrate aqueous solution

[0021] Pour quantitative deionized water into the potassium nitrate reaction kettle, then turn on the potassium nitrate reaction kettle to stir, after stirring for 2-5 minutes, open the jacketed steam valve of the potassium nitrate reaction kettle to heat, and add deionized water from the feeding hole while heating. The industrial potassium nitrate of 1-1.5 times the water quality, when the temperature of the solution rises to 60-80 ° C, the potassium hydroxide solution with a mass fraction of 20-40% prepared by pure potassium hydroxide is used to adjust the pH of the solution in the potassium nitrate reactor The value is 8.0-8.5, then turn on the discharge pump and related valves, so that the hot solution with a temperature of 60-80 ° C is first filtered through an ult...

Embodiment 2

[0026] Embodiment 2, a kind of preparation technology of industrialized superior grade pure potassium nitrate, the steps are as follows:

[0027] (1) Preparation of purified potassium nitrate aqueous solution

[0028] Pour 100L of deionized water into a 300L potassium nitrate reactor, and then turn on the potassium nitrate reactor to stir. After stirring for 2-5 minutes, open the jacketed steam valve of the potassium nitrate reactor for heating. Add 100Kg of industrial potassium nitrate, when the temperature of the solution rises to 60°C, adjust the pH value of the solution in the potassium nitrate reactor to 8.0 with a potassium hydroxide solution with a mass fraction of 20% prepared by superior pure potassium hydroxide, and then open Discharge pump and related valves, so that the hot solution with a temperature of 60 ° C is first filtered through an ultra-micro filter with a pore size of 0.2 μm, and then enters the flash concentration tank with a mass fraction of 20% prepare...

Embodiment 3

[0031] Embodiment 3, a kind of preparation technology of industrialized superior grade pure potassium nitrate, the steps are as follows:

[0032] (1) preparation of potassium nitrate aqueous solution

[0033] Pour 150L of deionized water into a 500L potassium nitrate reactor, and then turn on the potassium nitrate reactor to stir. After stirring for 2-5 minutes, turn on the jacketed steam valve of the potassium nitrate reactor for heating. Add 220Kg of industrial potassium nitrate, when the temperature of the solution rises to 80°C, adjust the pH value of the solution in the potassium nitrate reactor to 8.5 with a potassium hydroxide solution with a mass fraction of 40% prepared by superior pure potassium hydroxide, and then open The discharge pump and related valves, so that the hot solution with a temperature of 80 ° C is first filtered through an ultra-micro filter with a pore size of 1 μm, and then enters the flash concentration tank with a dilute solution with a mass frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com