A kind of preparation method of nanometer rare earth oxide powder

A nano-rare earth and oxide technology, applied in the direction of rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, nanotechnology, etc., can solve the problems of uneven particle morphology and obtain nanoparticles, etc. Achieve low production cost, reduce surface tension, and improve the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Add 0.034g cocamidopropyl betaine to the neodymium chloride solution of 100mL0.5mol / L, prepare solution A, add 0.120g cocamidopropyl betaine in the ammonium bicarbonate solution of 350ml0.5mol / L Betaine, prepared to obtain solution B. Make the concentration of cocamidopropyl betaine in the solution be 0.001mol / L.

[0050] 2) Add solution A prepared in step 1) dropwise to solution B at a rate of 1 mL / min to obtain a rare earth precipitate. During the dropping process, the reaction system was stirred at a speed of 600rpm. After the dropping was completed, the stirring was continued for 1 hour, then aged for 4 hours, filtered, washed with deionized water for 2-5 times, and then washed with ethanol for 2-6 times to obtain Sediment filter cake. Put the above precipitate filter cake into a vacuum drying oven, and vacuum dry at 80° C. for 4 hours.

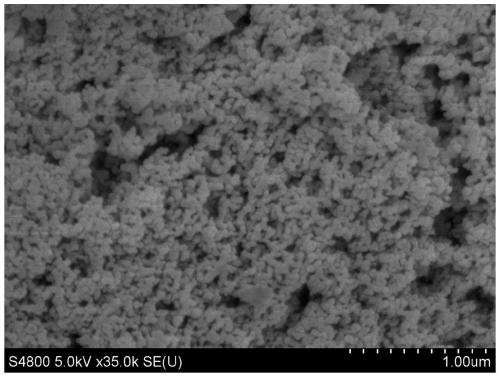

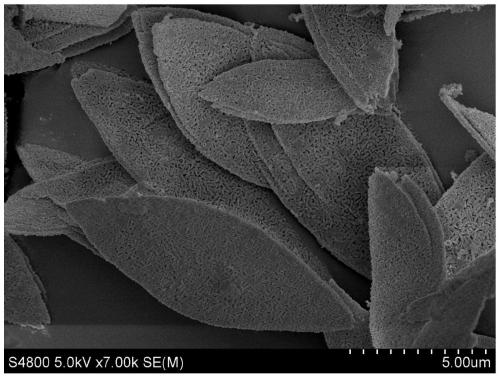

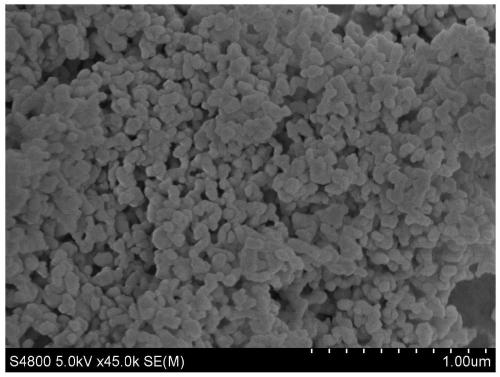

[0051] 3) Calcining the rare earth precipitate prepared in step 2) to obtain nano-neodymium oxide powder. The precipitate ...

Embodiment 2

[0054] 1) Add 0.34g cocamidopropyl betaine to the neodymium chloride solution of 100mL0.5mol / L, prepare solution A, add 1.2g cocamidopropyl betaine in the ammonium bicarbonate solution of 350ml0.5mol / L Betaine, prepared to obtain solution B. Make the concentration of cocamidopropyl betaine in the solution be 0.01mol / L.

[0055] 2) Add solution A prepared in step 1) dropwise to solution B at a rate of 1.5 mL / min to obtain a rare earth precipitate. During the dropping process, the reaction system was stirred at a speed of 700rpm. After the dropping was completed, the stirring was continued for 1 hour, then aged for 4 hours, filtered, washed with deionized water for 2-5 times, and then washed with ethanol for 2-6 times to obtain Sediment filter cake. Put the above precipitate filter cake into a vacuum drying oven, and vacuum dry at 100° C. for 4 hours.

[0056] 3) Calcining the rare earth precipitate prepared in step 2) to obtain nano-neodymium oxide powder. The precipitate w...

Embodiment 3

[0059] 1) Add 0.68g cocamidopropyl betaine to the neodymium chloride solution of 100mL0.5mol / L, prepare solution A, add 2.4g cocamidopropyl betaine in the ammonium bicarbonate solution of 350ml0.5mol / L Betaine, prepared to obtain solution B. Make the concentration of cocamidopropyl betaine in the solution be 0.02mol / L.

[0060] 2) Add solution A prepared in step 1) dropwise to solution B at a rate of 1 mL / min to obtain a rare earth precipitate. During the dropping process, the reaction system was stirred at a speed of 800rpm. After the dropping was completed, the stirring was continued for 2 hours, then aged for 3 hours, filtered, washed with deionized water for 2-5 times, and then washed with ethanol for 2-6 times to obtain Sediment filter cake. Put the above-mentioned precipitate filter cake into a vacuum drying oven, and vacuum-dry at 90° C. for 5 hours.

[0061] 3) Calcining the rare earth precipitate prepared in step 2) to obtain nano-neodymium oxide powder. The preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com