Phenylhydrazine hydrochloride production waste liquid treatment method and application thereof

A technology for phenylhydrazine hydrochloride and waste liquid treatment, applied in multi-stage water treatment, water/sewage treatment, natural water treatment and other directions, can solve problems such as environmental pollution and resource waste, improve economic benefits, avoid emissions, and save production The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

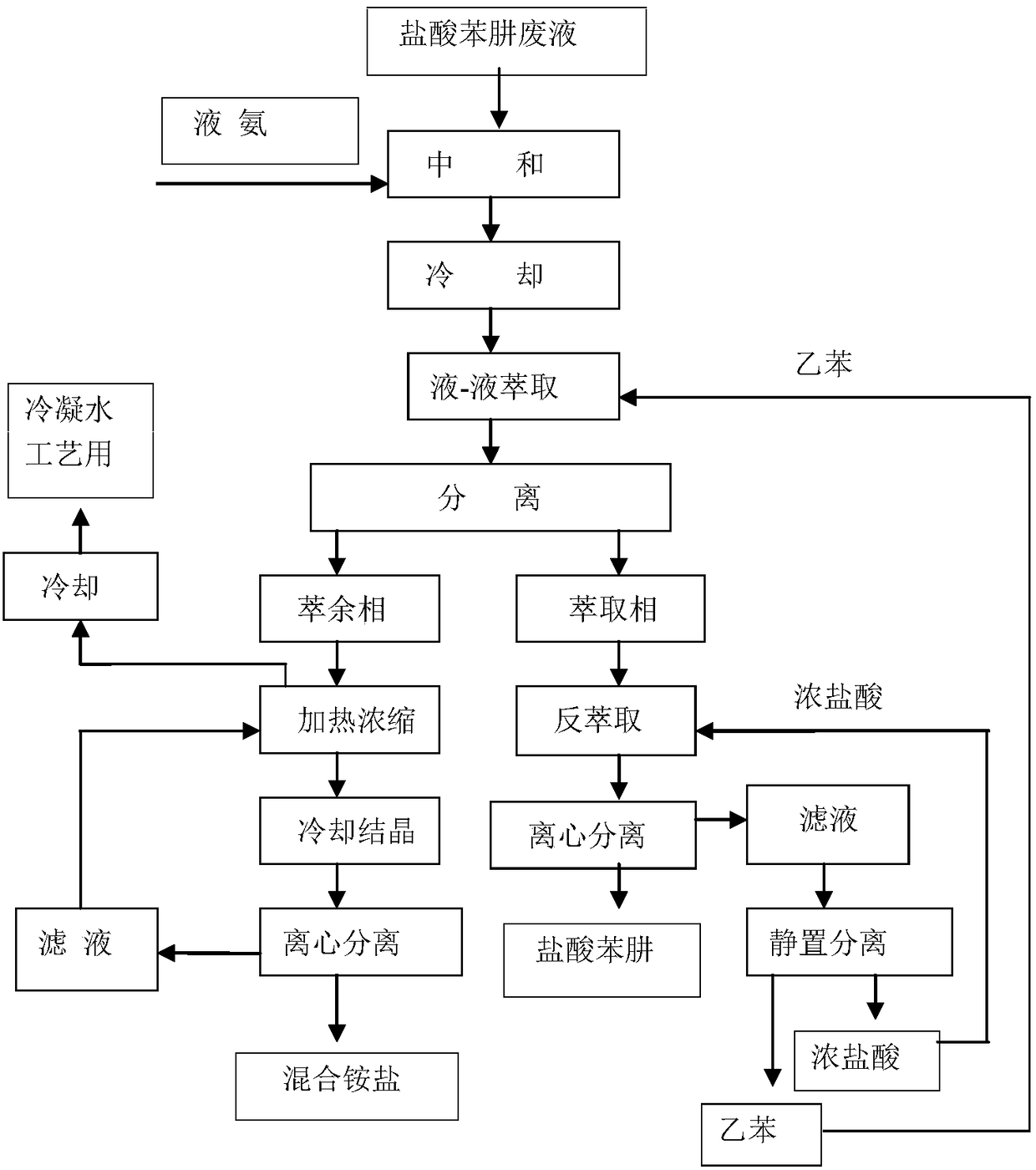

[0040] A kind of phenylhydrazine hydrochloride production waste liquid processing method, process step comprises:

[0041] 1) Transfer the waste liquid from the production of phenylhydrazine hydrochloride to the reaction kettle, add liquid ammonia while stirring at room temperature for neutralization reaction, until the pH value of the waste liquid reaches 9.5, stop adding liquid ammonia, and continue stirring for 20 minutes.

[0042] The neutralization reaction equation is:

[0043] Ar-NH-NH 2 ·HCl+NH 3 →Ar-NH-NH 2 +NH 4 Cl

[0044] HCl+NH 3 →NH 4 Cl

[0045] NH 4 HSO 4 +NH 3 →(NH 4 ) 2 SO 4

[0046] NH 4 HSO 3 +NH 3 →(NH 4 )2 SO 3 .

[0047] 2) The neutralized solution is transported to the extraction tower for extraction treatment, the flow rate of the solution and ethylbenzene extractant entering the extraction tower is controlled, and the extraction temperature is controlled within the range of 20°C to 25°C, so that the extraction operation can be carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com