Decorative slab for whole house decoration and its preparation method

A decorative plate and additive technology, applied in the field of building decoration materials and materials, can solve the problems of flame retardant, acid and alkali resistance, heat resistance, wear resistance, compression resistance, waterproof and moisture resistance, oil pollution resistance, high porosity, and resistance to oil pollution. Grinding, acid and alkali resistance, poor pressure resistance and other problems, to achieve the effect of simple decoration process, moderate softness, and long setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

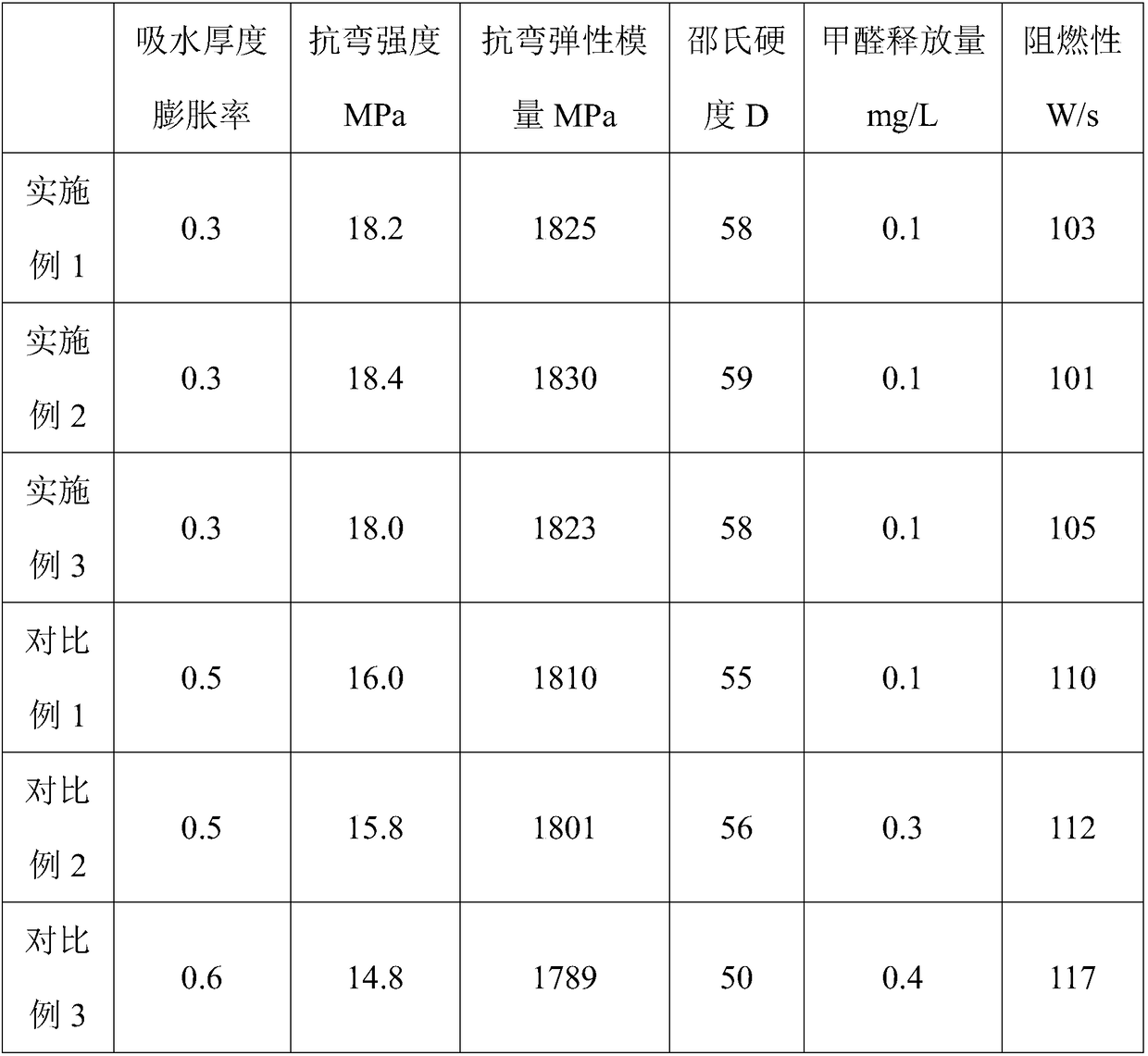

Embodiment 1

[0038] A decorative board for whole house decoration, which is made of the following materials by weight:

[0039] 37 parts of wood flour, 33 parts of polyvinyl chloride, 20 parts of light calcium powder, 4 parts of heavy calcium powder, 3 parts of polyisocyanate, 2 parts of calcium-zinc composite stabilizer, 1 part of additive, wherein the additive consists of 18.5 parts of polyethylene wax , 30 parts of AC yellow foaming agent, 18.5 parts of NC white foaming agent, 13 parts of stearic acid, 1.5 parts of Zhongluohuang, and 18 parts of bamboo fragrance powder are mixed according to the weight ratio.

[0040] The preparation process of the decorative board used for the whole house is as follows:

[0041] (1) Configure additives: input the raw materials contained in the additives and the specific amount of raw materials into the computer for material selection and proportioning, and stir evenly.

[0042] (2) Small material batching: Calculate the feeding amount of various stabi...

Embodiment 2

[0056] A decorative board for whole house decoration, which is made of the following materials by weight:

[0057] 36 parts of wood flour, 33 parts of polyvinyl chloride, 21 parts of light calcium powder, 5 parts of heavy calcium powder, 2 parts of polyisocyanate, 1.8 parts of calcium-zinc composite stabilizer, 1.2 parts of additives, wherein the additives consist of the following ingredients: polyethylene wax 18.5 parts , 30 parts of AC yellow foaming agent, 18.5 parts of NC white foaming agent, 13 parts of stearic acid, 1.5 parts of Zhongluohuang, and 18 parts of bamboo fragrance powder are mixed according to the weight ratio.

Embodiment 3

[0059] A decorative board for whole house decoration, which is made of the following materials by weight:

[0060] 38 parts of wood flour, 32 parts of polyvinyl chloride, 18 parts of light calcium powder, 6 parts of heavy calcium powder, 2.7 parts of polyisocyanate, 1.9 parts of calcium-zinc composite stabilizer, 1.4 parts of additives, wherein the additives consist of the following ingredients: polyethylene wax 18.5 parts , 30 parts of AC yellow foaming agent, 18.5 parts of NC white foaming agent, 13 parts of stearic acid, 1.5 parts of Zhongluohuang, and 18 parts of bamboo fragrance powder are mixed according to the weight ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com